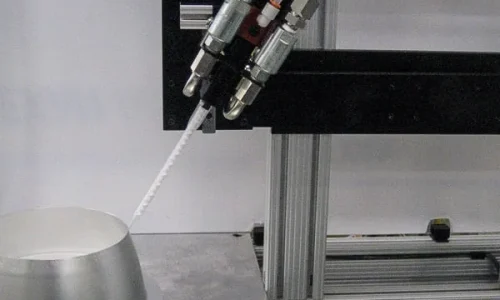

Discover similar options and compatible equipment, accessories, and consumables that pair seamlessly with this product—helping you evaluate alternatives or integrate complementary components for consistent, reliable, and precise dispensing performance.

Optical Communications and Connector Dispensing

-

Bonding fiber optic connectors with low-residue epoxies for clear signal transmission

-

Sealing optical devices against environmental factors using precise ratio control

-

Assembly of compact communication modules with minimal material waste