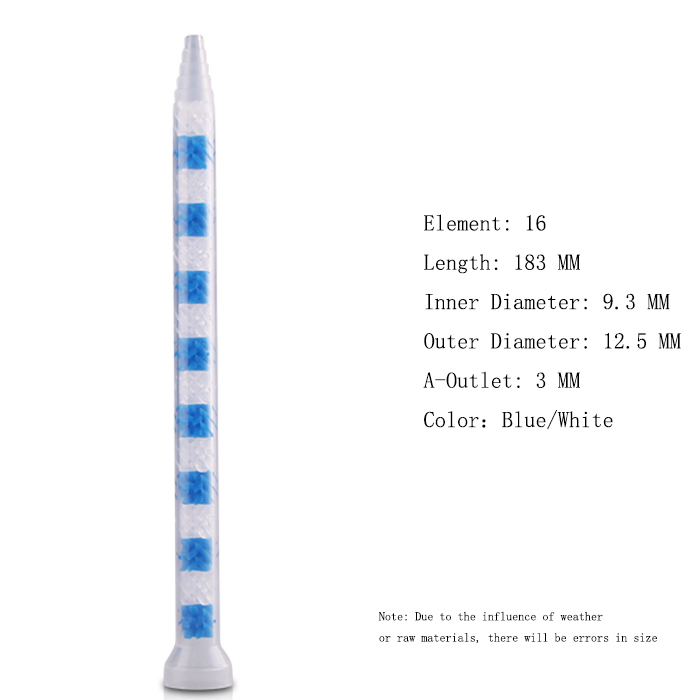

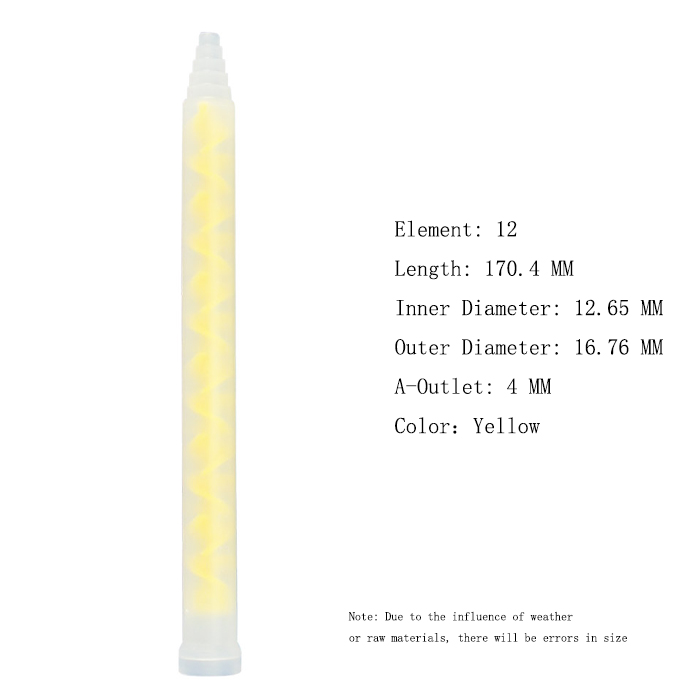

Discover similar options and compatible equipment, accessories, and consumables that pair seamlessly with this product—helping you evaluate alternatives or integrate complementary components for consistent, reliable, and precise dispensing performance.

Medical Device Assembly, Industrial Prototyping & Precision Repair

-

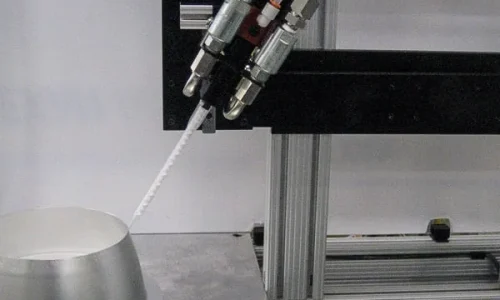

Consistent, contamination-minimized dispensing for controlled production environments

-

Rapid material switching during prototyping and low-volume production

-

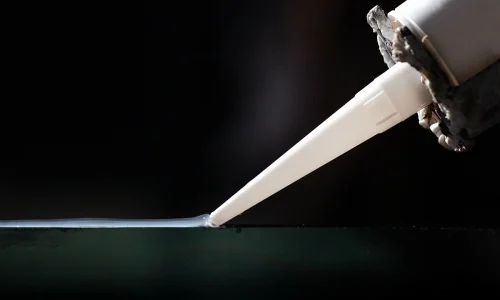

Pin-point adhesive placement for miniature assemblies and delicate repairs