A Guide to Maintenance and Storage of Epoxy Mixing Nozzles

In this blog, we will provide you with valuable tips and guidelines to maintain and store epoxy mixing nozzles effectively.

The following are selected blog posts about our products. If you do not find the information you need, you can contact us and we will get back to you within 24 hours.

In this blog, we will provide you with valuable tips and guidelines to maintain and store epoxy mixing nozzles effectively.

In this blog post, we will discuss the different ratios for mixing epoxy and how to mix epoxy properly.

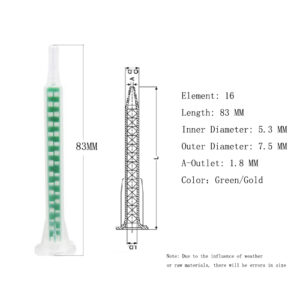

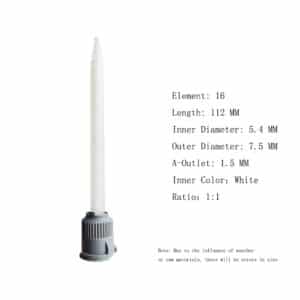

In this blog, we will discuss the benefits of using epoxy mixing nozzles, the different types of nozzles available, and the proper use and maintenance of these tools.

In this blog post, we will discuss epoxy mixing nozzles in detail, including their features, benefits, and how to use them effectively.

In this blog, we will explore the design and functionality of epoxy mixing nozzles, their advantages and applications, and how to properly use them.

In this blog, we will explore the differences between plastic and stainless steel dispensing tips, including their advantages and disadvantages.

This article aims to discuss the relationship between epoxy mixing nozzles and syringe barrels and provide instructions on how to use them.

In this blog post, we will discuss what dental mixing tips are, how they work, and why they are important in the dental industry.

In this blog, we will provide you with tips for using static mixing nozzles. 1.Choose the right size nozzle; 2.Check the flow rate; 3.Use the right pressure.

In this blog post, we will take a closer look at static mixing nozzles, including how they work, their various applications, and the advantages they offer.

In this ultimate guide to dispensing tips, we will explore seven types of dispensing tips, their features, and their ideal applications.

In this ultimate guide, we will explore the basics of two-component mixer nozzles, including their design, functionality, and applications.

Address: Room 1305,

Tiandu Building,

No. 211 Changjiang Road,

Huqiu District,

Suzhou, Jiangsu,

China

Tel: +8618706202541

Emails: info@btektech.com