In the world of fluid mixing and dispensing, static mixing nozzles have become a common tool used in a variety of industries. These nozzles offer a reliable and efficient method of mixing two or more fluids together, which is important for a wide range of applications. Whether it’s for chemical processing, food and beverage production, or medical device manufacturing, static mixing nozzles are an essential component of many production processes.

In this blog post, we will take a closer look at static mixing nozzles, including how they work, their various applications, and the advantages they offer. We will also explore the features of a high-quality static mixing nozzle and provide some tips for selecting the right one for your application.

What is Static Mixing Nozzle?

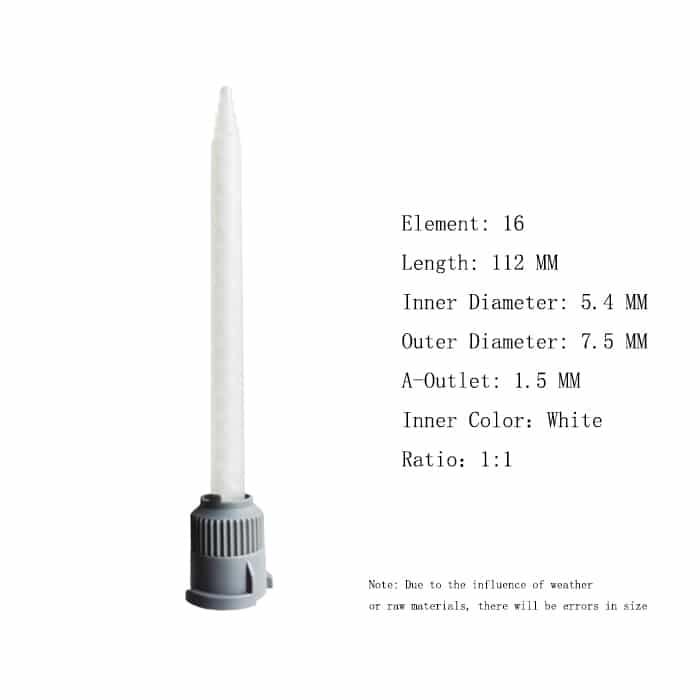

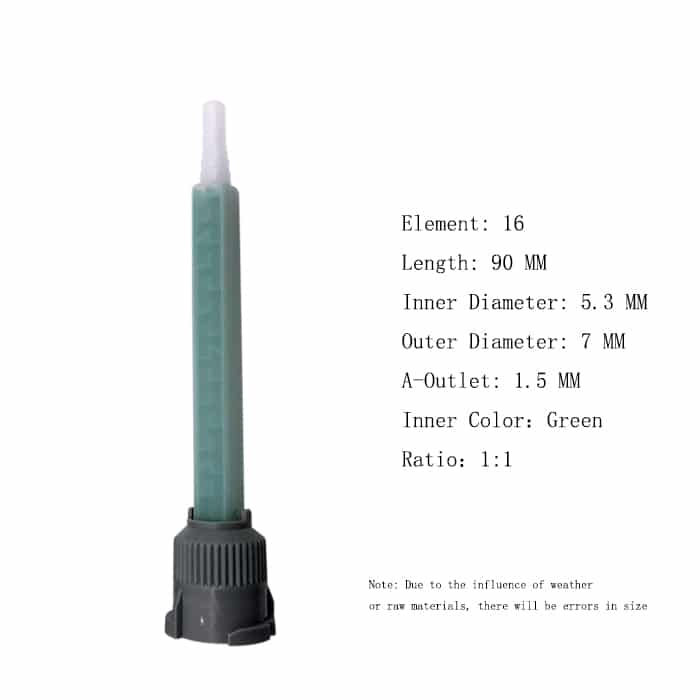

The static mixing nozzle is a device that is designed to mix two or more fluids together as they pass through the nozzle. These nozzles consist of a series of static mixing elements, which are arranged in a specific pattern to promote thorough mixing of the fluids. The elements are typically made from a variety of materials, including plastic, stainless steel, and ceramic.

The design of a static mixing nozzle can vary depending on the application. For example, some nozzles may have a straight or spiral design, while others may feature a helical or quad helix design. Regardless of the specific design, all static mixing nozzles are designed to provide efficient and consistent mixing of fluids.

How Does the Static Mixing Nozzle Work?

Static mixing nozzles work by using a series of static mixing elements to promote thorough mixing of fluids. The elements are designed to cause turbulent flow, which helps to distribute the fluids evenly and ensure that they are thoroughly mixed.

When two or more fluids are introduced into the nozzle, they are forced through the mixing elements, which causes them to mix together. The number and arrangement of the mixing elements can vary depending on the application and the desired level of mixing.

One of the key advantages of static mixing nozzles is that they don’t require any external energy source to mix the fluids. Instead, they rely on the flow of the fluids through the nozzle to promote mixing. This makes them an efficient and cost-effective solution for a wide range of applications.

Applications of Static Mixing Nozzles

Static mixing nozzles are used in a wide range of applications across various industries. Some of the most common applications include:

-

Chemical processing

Static mixing nozzles are commonly used in chemical processing to mix two or more chemicals together. This is important for ensuring that the chemicals are properly blended and that the desired chemical reaction occurs.

-

Food and beverage production

Static mixing nozzles are used in the production of a variety of food and beverage products, such as soft drinks and dairy products. They are used to mix ingredients together to ensure that they are properly blended and that the final product has the desired consistency and texture.

-

Medical device manufacturing

Static mixing nozzles are used in the manufacturing of medical devices, such as catheters and syringes. They are used to mix together two or more components of the device, such as a polymer and a hardener, to create a strong and durable product.

Advantages of Static Mixing Nozzles

There are several advantages to using static mixing nozzles for fluid mixing and dispensing, including:

-

Efficient mixing

Static mixing nozzles provide efficient and consistent mixing of fluids, which is important for ensuring that the final product meets the desired specifications.

-

Cost-effective

Static mixing nozzles don’t require any external energy source to mix fluids, which makes them a cost-effective solution for a wide range of applications.

-

Easy to use

Static mixing nozzles are easy to install and use, which makes them a convenient solution for many production processes.

-

Reduced waste

Static mixing nozzles help to minimize waste by ensuring that fluids are thoroughly mixed and evenly distributed, which reduces the likelihood of overuse or underuse of materials.

-

Versatile

Static mixing nozzles can be used for a wide range of applications and can handle a variety of fluid types, including viscous liquids, high solids content, and abrasive materials.

Features of a High-Quality Static Mixing Nozzle

When selecting a static mixing nozzle for your application, there are several features to consider:

-

Material

The material used to construct the mixing elements should be appropriate for the type of fluids being mixed. For example, if the fluids are abrasive, a ceramic or tungsten carbide mixing element may be more appropriate than a plastic element.

-

Mixing element design

The design of the mixing elements can vary depending on the application. For example, a helical design may be more appropriate for low viscosity fluids, while a quad helix design may be more appropriate for high viscosity fluids.

-

Size

The size of the nozzle should be appropriate for the desired flow rate and the size of the mixing chamber.

-

Compatibility

The nozzle should be compatible with the materials being used and the equipment being used for dispensing.

-

Durability

The nozzle should be made from high-quality materials and be designed to withstand the wear and tear of regular use.

Conclusion

Static mixing nozzles are an important tool for fluid mixing and dispensing in a variety of industries. They offer efficient and consistent mixing of fluids, which is important for ensuring that the final product meets the desired specifications. When selecting a static mixing nozzle for your application, it’s important to consider factors such as material, mixing element design, size, compatibility, and durability. By selecting the right static mixing nozzle, you can ensure that your production processes run smoothly and efficiently.