Dispensing tips are crucial for various industries that require precision dispensing of fluids such as adhesives, solvents, paints, and other materials. They come in various shapes and sizes, each designed for a specific task. In this ultimate guide to dispensing tips, we will explore seven types of dispensing tips, their features, and their ideal applications.

Angled Dispensing Tips

Angled dispensing tips are designed to dispense fluids at a specific angle, making them ideal for applications that require precision dispensing. These tips are commonly used in industries such as electronics, automotive, and medical devices. Angled dispensing tips come in various angles, including 45, 90, and 120 degrees, to provide flexibility in the application process.

One of the main advantages of angled dispensing tips is their ability to reach difficult areas that may be challenging to access with straight tips. These tips can also be used to dispense materials at a specific location, reducing the need for additional equipment or tools.

Brush Dispensing Tips

Brush dispensing tips are ideal for applications that require precise and controlled application of fluids. They come with a brush-like tip that allows the fluid to be applied evenly and smoothly, making them ideal for applications such as painting, gluing, and sealing.

One of the main advantages of brush dispensing tips is their versatility. They can be used for a wide range of applications, including those that require fine detail work. They are also ideal for use with materials that require a thin and even layer of application, such as coatings or adhesives.

Flexible Dispensing Tips

Flexible dispensing tips are designed to provide flexibility in the application process, allowing the user to reach difficult areas or apply fluids at specific angles. They are commonly used in industries such as electronics and medical devices, where precision and flexibility are critical.

One of the main advantages of flexible dispensing tips is their ability to bend and flex without breaking. This makes them ideal for use with materials that require precise application but may be challenging to access with straight tips. Flexible dispensing tips also come in various lengths, making them ideal for use with long and narrow areas.

Oval Dispensing Tips

Oval dispensing tips are designed to provide a wide and even application of fluids, making them ideal for applications such as coating, gluing, and sealing. They come in various sizes and are commonly used in industries such as automotive, aerospace, and construction.

One of the main advantages of oval dispensing tips is their ability to provide a wide and even application of fluids. This makes them ideal for use with materials that require a thin and even layer of application. Oval dispensing tips are also easy to clean and maintain, making them a popular choice for industries that require frequent use.

PTFE Dispensing Tips

PTFE dispensing tips are made from a high-quality material known as polytetrafluoroethylene (PTFE). This material is known for its non-stick properties, making it ideal for use with materials that are difficult to dispense or clean.

One of the main advantages of PTFE dispensing tips is their ability to provide a consistent and even application of fluids. They are also easy to clean and maintain, making them ideal for industries that require frequent use. PTFE dispensing tips are commonly used in industries such as electronics, medical devices, and automotive.

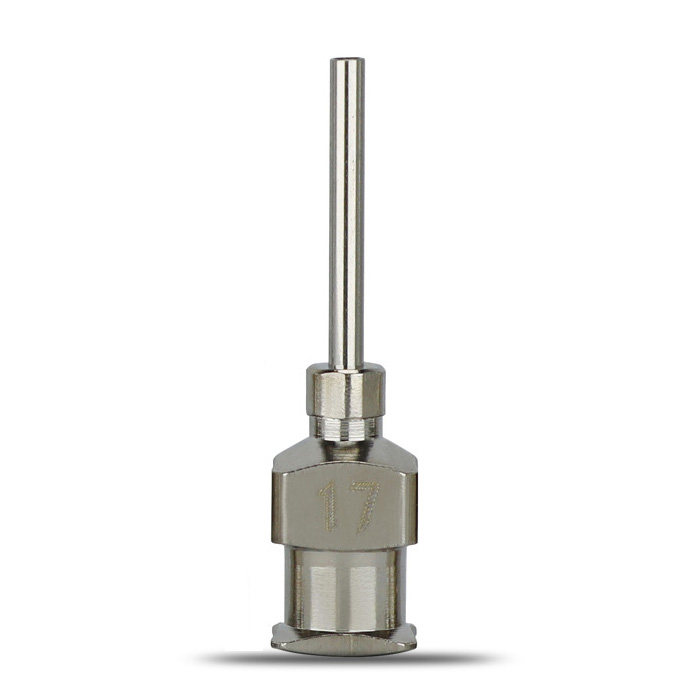

Stainless Steel Dispensing Tips

Stainless steel dispensing tips are designed to provide durability and longevity, making them ideal for applications that require frequent use. They come in various sizes and are commonly used in industries such as aerospace, pharmaceutical, and food and beverage.

One of the main advantages of stainless steel dispensing tips is their durability. They are resistant to corrosion, making them ideal for use with materials that may be corrosive. Stainless steel dispensing tips are also easy to clean and maintain, making them a popular choice for industries that require frequent use.

Tapered Dispensing Tips

Tapered dispensing tips are designed to provide a precise and controlled flow of fluids, making them ideal for applications that require accuracy and consistency. They come in various sizes and are commonly used in industries such as automotive, aerospace, and electronics.

One of the main advantages of tapered dispensing tips is their ability to provide a precise and controlled flow of fluids. This makes them ideal for use with materials that require a consistent flow rate. Tapered dispensing tips are also easy to clean and maintain, making them a popular choice for industries that require frequent use.

Conclusion

In conclusion, dispensing tips are an essential component for industries that require precision and accuracy in the application of fluids. The seven types of dispensing tips we have explored in this ultimate guide each offer unique features and advantages for specific applications. By understanding the different types of dispensing tips and their ideal applications, you can choose the right tip for your specific needs and achieve optimal results in your work.