Static mixing nozzles are used to mix two or more components together in a precise and controlled manner. They are commonly used in various industries including adhesive, sealant, and coatings industries. Static mixing nozzles are known for their efficiency and accuracy in mixing, which is why they are preferred over other mixing methods. In this blog, we will provide you with tips for using static mixing nozzles.

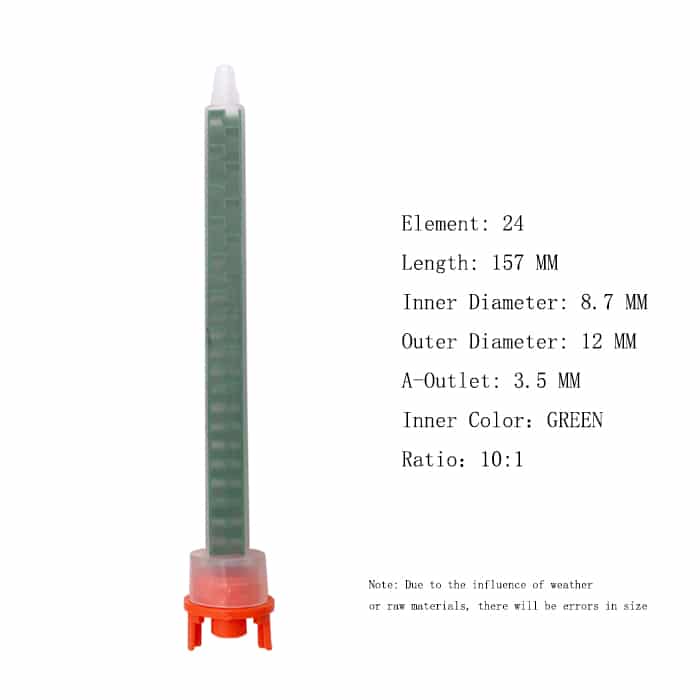

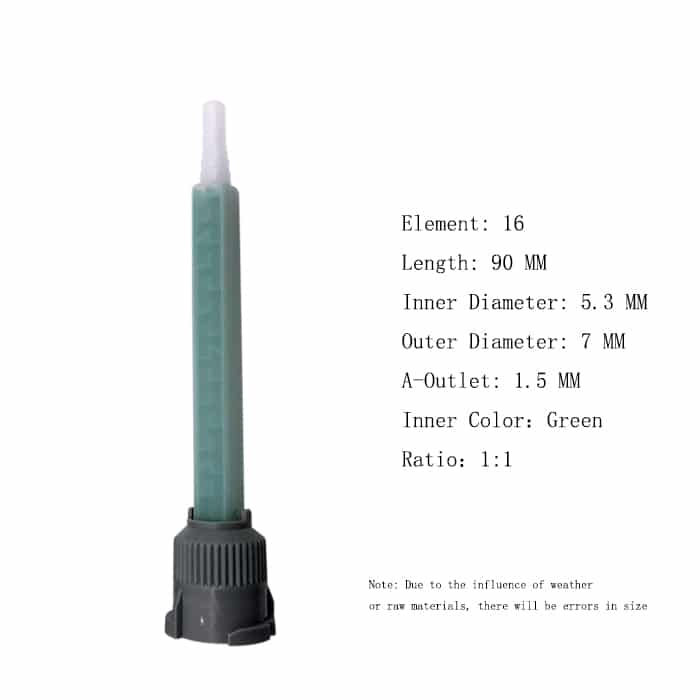

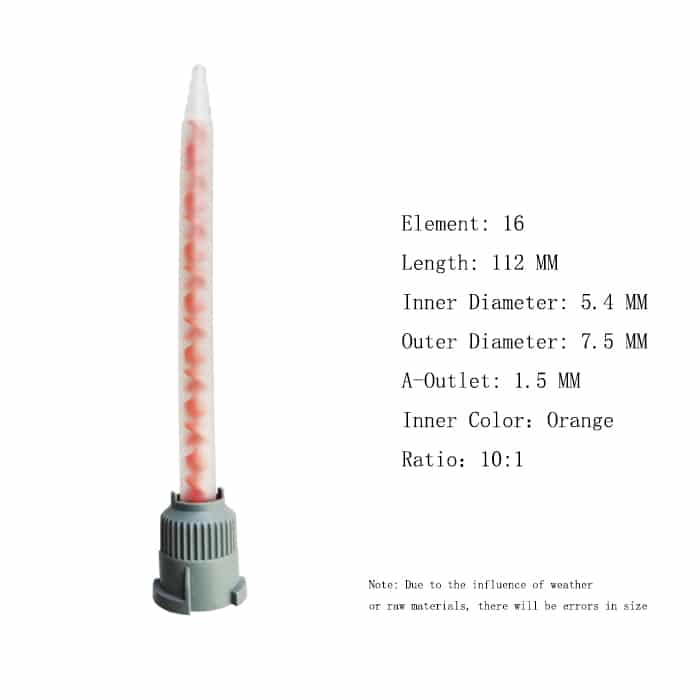

Choose the right size nozzle

Choosing the right size nozzle is important to ensure that the right amount of material is dispensed and mixed. Nozzles come in different sizes, and the size of the nozzle should be based on the amount of material that needs to be dispensed. A larger nozzle will dispense more material, while a smaller nozzle will dispense less material.

Check the flow rate

The flow rate of the material being dispensed is important to ensure that the nozzle is working correctly. The flow rate can be checked by using a flow meter, which will give an accurate reading of the flow rate. If the flow rate is too low, the material may not be mixed properly, while a flow rate that is too high may cause the material to be dispensed too quickly.

Use the right pressure

The pressure used to dispense the material through the nozzle is also important. The pressure should be adjusted to ensure that the material is being dispensed at the correct rate. If the pressure is too low, the material may not be dispensed at the right rate, while a pressure that is too high may cause the material to be dispensed too quickly.

Use the correct mixing ratio

The correct mixing ratio should be used to ensure that the material is mixed properly. The mixing ratio is the ratio of the two or more components that are being mixed together. The mixing ratio can be found on the product label, and it is important to follow the manufacturer’s instructions for the correct mixing ratio.

Clean the nozzle

Cleaning the nozzle after use is important to ensure that it is ready for the next use. If the nozzle is not cleaned properly, it may cause the material to be dispensed improperly, and the mixing ratio may be off. The nozzle should be cleaned with a solvent that is compatible with the material being dispensed.

Use the nozzle at the correct temperature

The temperature at which the material is dispensed is important to ensure that it is mixed properly. If the material is dispensed at a temperature that is too low or too high, it may affect the mixing ratio and cause the material to be dispensed improperly. The temperature should be checked and adjusted accordingly.

Store the nozzles properly

Storing the nozzles properly is important to ensure that they are ready for use when needed. The nozzles should be stored in a dry and cool place, away from direct sunlight. It is also important to ensure that the nozzles are stored in a way that they do not get damaged.

Use the nozzle once

Static mixing nozzles are designed for single use only. They should not be reused as this may affect the accuracy of the mixing and cause the material to be dispensed improperly. After use, the nozzle should be discarded.

Use the nozzle at the right time

Using the nozzle at the right time is important to ensure that the material is mixed properly. The nozzle should be used immediately after it is attached to the cartridge or syringe. If the material is left to sit for too long, it may start to harden, making it difficult to dispense and mix.

Use the right type of nozzle

There are different types of nozzles that are designed for different applications. It is important to use the right type of nozzle for the specific application. For example, if you are working with a thick material, you may need a nozzle with larger mixing elements to ensure that the material is mixed properly. On the other hand, if you are working with a thinner material, you may need a nozzle with smaller mixing elements to ensure that the material is mixed efficiently.

Conclusion

Static mixing nozzles are a very common and easy to use tool, but paying attention to the tips mentioned above during use will allow you to achieve higher efficiency. Of course it is also very important to choose a professional static mixing nozzle manufacturer so that you can ensure that your production schedule will not be delayed due to the quality and availability of static mixing nozzles