Epoxy is a commonly used adhesive in various industries for its excellent bonding properties. Epoxy adhesives are made of two parts – resin and hardener, which are mixed in a certain ratio to activate the adhesive. The mixing of epoxy is a critical step in achieving a strong bond. Mixing nozzles and syringe barrels are two essential tools used to mix and apply epoxy adhesive. This article aims to discuss the relationship between epoxy mixing nozzles and syringe barrels and provide instructions on how to use them.

Understanding Epoxy Mixing Nozzles

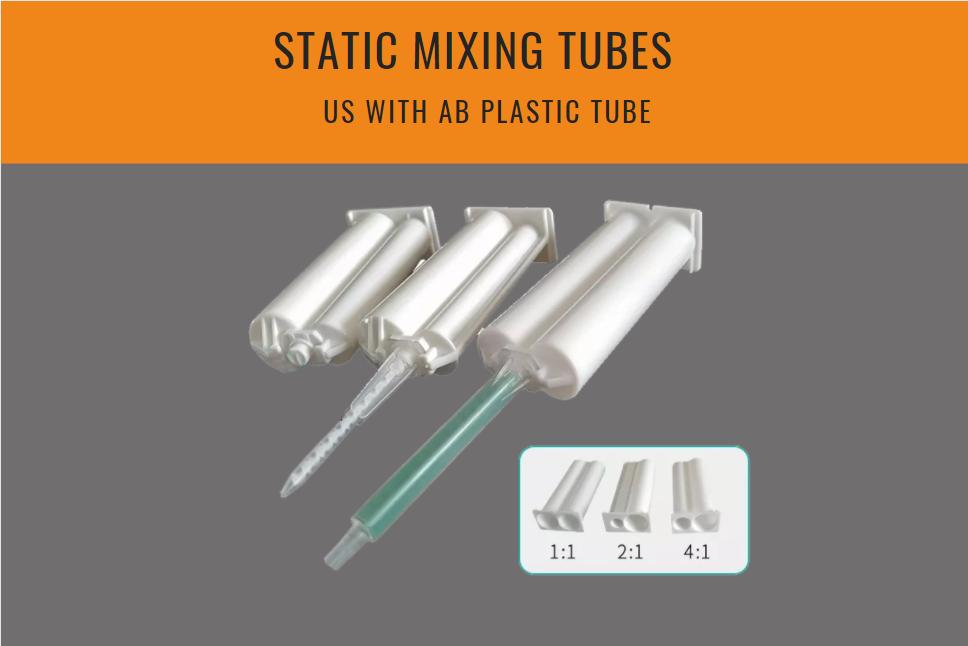

Epoxy mixing nozzles are disposable plastic attachments that fit onto the end of a syringe barrel. They are designed to mix the two parts of the epoxy adhesive thoroughly and evenly. Mixing nozzles have a series of internal chambers and helical elements that ensure the complete mixing of the epoxy resin and hardener.

Mixing nozzles come in different sizes, shapes, and designs, depending on the application. Some have a straight, tapered tip, while others have a bend or curve for hard-to-reach areas. The size of the mixing nozzle is also essential, as it determines the flow rate and the amount of epoxy dispensed.

Understanding Syringe Barrels

Syringe barrels are plastic containers used to dispense the epoxy adhesive. They come in different sizes, ranging from 1cc to 60cc, depending on the application. Syringe barrels are typically made of clear or opaque plastic and have a plunger at one end that is used to push the epoxy adhesive out of the barrel.

Syringe barrels can be used with or without mixing nozzles, but using a mixing nozzle is recommended for most applications. Using a mixing nozzle ensures the proper mixing of the epoxy adhesive and reduces waste.

The Relationship between Epoxy Mixing Nozzles and Syringe Barrels

The relationship between epoxy mixing nozzles and syringe barrels is essential for achieving the proper mix of the epoxy adhesive. Mixing nozzles are designed to fit onto the end of a syringe barrel, and the two work together to dispense and mix the epoxy adhesive.

When the two parts of the epoxy adhesive are mixed, a chemical reaction occurs, causing the adhesive to harden and bond. The speed at which the adhesive hardens depends on the temperature, humidity, and the ratio of the resin and hardener. Mixing nozzles and syringe barrels must be used correctly to ensure the proper mix of the epoxy adhesive and to achieve the desired bond strength.

How to Use Epoxy Mixing Nozzles and Syringe Barrels

Using epoxy mixing nozzles and syringe barrels is relatively simple, but it requires attention to detail to achieve the best results. Here are the steps to follow:

-

Step 1: Select the Right Mixing Nozzle and Syringe Barrel

Before you begin, select the right mixing nozzle and syringe barrel for your application. Consider the size of the area you need to cover, the flow rate of the epoxy, and the viscosity of the adhesive.

-

Step 2: Load the Syringe Barrel with Epoxy Adhesive

Remove the plunger from the syringe barrel and load it with the epoxy adhesive. Be sure to follow the manufacturer’s instructions for the correct mixing ratio.

-

Step 3: Attach the Mixing Nozzle to the Syringe Barrel

Attach the mixing nozzle to the end of the syringe barrel, making sure it fits snugly. Twist the nozzle until it is fully seated on the syringe barrel.

-

Step 4: Dispense the Epoxy Adhesive

Squeeze the plunger on the syringe barrel to dispense the epoxy adhesive. Be sure to apply an even amount of adhesive, and apply it quickly before the adhesive begins to harden.

-

Step 5: Mix the Epoxy Adhesive

After dispensing the epoxy adhesive, continue to squeeze the plunger on the syringe barrel to mix the two parts of the adhesive thoroughly. The mixing nozzle will ensure that the two parts are mixed evenly and thoroughly. Continue mixing until the epoxy adhesive is a uniform color and consistency.

-

Step 6: Apply the Epoxy Adhesive

Once the epoxy adhesive is thoroughly mixed, apply it to the surface to be bonded. Apply an even coat of adhesive, ensuring that it covers the entire surface to be bonded. Use a clean, dry cloth to wipe away any excess adhesive.

-

Step 7: Allow the Epoxy Adhesive to Cure

The curing time of the epoxy adhesive will depend on the temperature and humidity of the environment. Follow the manufacturer’s instructions for the recommended curing time.

Conclusion:

In conclusion, using epoxy mixing nozzles and syringe barrels is essential for achieving the proper mix of epoxy adhesive. Mixing nozzles are designed to fit onto the end of a syringe barrel, and the two work together to dispense and mix the epoxy adhesive. When used correctly, these tools ensure a strong bond and reduce waste. Following the steps outlined in this article will help you use epoxy mixing nozzles and syringe barrels correctly and achieve the desired bond strength.

We strongly recommend that you choose a reliable manufacturer when purchasing mixing nozzles and syringe barrels, as different manufacturers have their own standards for mixing nozzles and syringe barrels, and choosing a reliable manufacturer will not only save you the time of searching for matching products, but also get professional advice to get the best solution.

Btektech has extensive experience in manufacturing and selling mixing nozzles and syringe barrels, and our products have been sold worldwide for the past few years. Contact us and get a quote now!