The Ultimate Guide to Dispensing Equipment

Dispensing guns are handheld tools designed for applying adhesives, sealants, and other viscous materials.

The following are selected blog posts about our products. If you do not find the information you need, you can contact us and we will get back to you within 24 hours.

Dispensing guns are handheld tools designed for applying adhesives, sealants, and other viscous materials.

In the world of adhesives and sealants, precision and efficiency are crucial. Dispensing accessories play a vital role in ensuring that materials are applied accurately,

Square-grid mixers are suitable for high-viscosity adhesives and provide efficient mixing with minimal pressure drop.

A caulking gun is a handheld tool designed to hold and dispense tube sealants, adhesives, or caulk.

Manual adhesive applicators are handheld tools that allow for precise control over the application process.

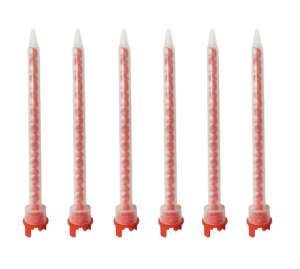

The right dispensing tip ensures proper mixing of the adhesive components, consistent application, and minimal waste, thereby enhancing the overall performance and efficiency of the adhesive system.

Syringe barrels are versatile and can be used with a variety of Polyurea formulations, making them suitable for a wide range of applications.

Dispensing tips for silicone applications come in various types and sizes, each suited for different dispensing needs.

One of the key features of dispensing syringe barrels is their ability to maintain the correct ratio of the two components throughout the dispensing process.

Static mixing nozzles are commonly used to apply silicone sealants and adhesives for sealing and bonding applications.

Dual cartridge syringe barrels are typically made of high-quality plastic or metal to ensure compatibility with a wide range of materials.

Epoxy mixing nozzles play a critical role in 2K dispensing systems by facilitating the thorough mixing of two-component materials before they are applied.

Address: Room 1305,

Tiandu Building,

No. 211 Changjiang Road,

Huqiu District,

Suzhou, Jiangsu,

China

Tel: +8618706202541

Emails: info@btektech.com