In the realm of industrial mixing, static mixers stand out as ingenious devices that facilitate the blending of fluids without the need for any moving parts. These mixers, also known as motionless or inline mixers, offer a simple yet highly efficient solution for homogenizing Polyurea, a versatile material widely used in coating, sealing, and lining applications.

What are Static Mixers?

Static mixers are devices designed to blend two or more components by exploiting the energy present in the flow of the materials themselves. Unlike dynamic mixers, which rely on mechanical agitation, static mixers achieve mixing through a series of stationary elements within a pipe or tube. These elements, known as mixing elements or baffles, are strategically placed to induce chaotic advection, thereby ensuring thorough blending of the components.

How do Static Mixers Work?

The operation of static mixers is based on the principle of dividing and recombining flow streams to promote mixing. As the components flow through the mixer, they are split and redirected multiple times by the mixing elements. This process creates layers of fluid that continuously fold over each other, resulting in intimate mixing without the need for external agitation.

Benefits of Using Static Mixers for Polyurea

Static mixers offer a range of benefits that make them an ideal choice for mixing Polyurea in industrial applications. Here are some key advantages:

1. Efficient Mixing

Static mixers provide efficient and thorough mixing of Polyurea components. The static mixing elements create turbulence and shearing forces that help break down any agglomerates and ensure uniform distribution of the components. This results in a homogenous mixture with consistent properties.

2. Consistent Quality

The precise design of static mixers ensures that the mixing process is consistent, leading to uniformity in the final product. This is crucial for applications where product quality and performance are paramount, such as in coatings, adhesives, and sealants.

3. Simple Design and Operation

Static mixers have a simple design and do not require any external power source or moving parts. This makes them easy to install, operate, and maintain. They can be easily integrated into existing processing lines with minimal disruption.

4. Versatility

Static mixers are versatile and can handle a wide range of flow rates and viscosities. This makes them suitable for various types of Polyurea formulations, from low-viscosity coatings to high-viscosity sealants. They can also be used with different sizes of pipes and tubing.

5. Cost-Effective

Due to their simple design and efficient operation, static mixers are cost-effective compared to other mixing methods. They require less maintenance and consume less energy, leading to overall cost savings in the long run.

6. Environmentally Friendly

Static mixers are environmentally friendly as they do not require the use of additional mixing agents or chemicals. This reduces waste and minimizes the environmental impact of the mixing process.

Types of Static Mixers for Polyurea

Static mixers come in various designs, each suited for different applications and mixing requirements. When it comes to Polyurea mixing, several types of static mixers are commonly used. Here are some of the most common types:

1. Helical Static Mixers

Helical static mixers, also known as twisted static mixers, are among the most popular choices for Polyurea mixing. They feature a series of twisted elements within a tube that create a swirling motion, promoting thorough mixing of the components. Helical mixers are effective for a wide range of viscosities and flow rates.

2. Tab Static Mixers

Tab static mixers consist of flat, rectangular tabs or elements that are stacked in a tube. The tabs create turbulence and shearing forces, ensuring thorough mixing of Polyurea components. Tab mixers are suitable for applications requiring precise mixing and can handle high-viscosity materials.

3. High-Flow Static Mixers

High-flow static mixers are designed to handle large volumes of material while maintaining efficient mixing. They feature a larger diameter and longer mixing elements compared to standard mixers, allowing for higher flow rates. High-flow mixers are ideal for applications where speed and volume are crucial.

4. Low-Pressure Drop Static Mixers

Low-pressure drop static mixers are designed to minimize pressure drop while ensuring effective mixing. They feature a streamlined design that reduces resistance to flow, making them suitable for applications where maintaining a consistent flow rate is important.

5. Multi-Element Static Mixers

Multi-element static mixers combine multiple mixing elements in a single unit to enhance mixing efficiency. By using different types of elements in sequence, these mixers can achieve thorough mixing in a compact space. Multi-element mixers are ideal for applications where space is limited or where a high degree of mixing is required.

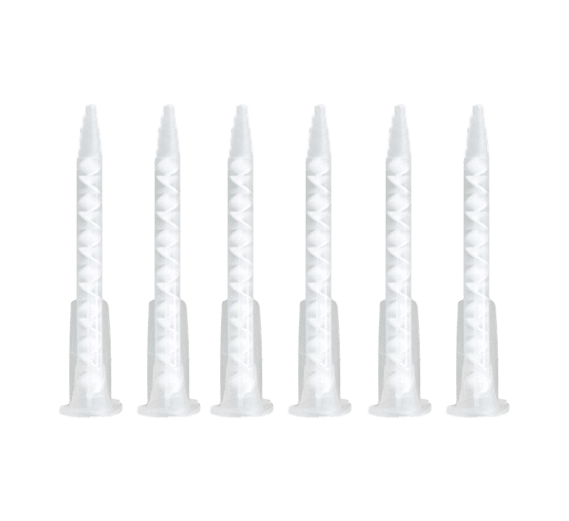

6. Disposable Static Mixers

Disposable static mixers are designed for single-use applications where cross-contamination or cleaning is a concern. These mixers are often used with cartridge-based dispensing systems for convenient and hygienic mixing of Polyurea components.

These are just a few examples of the types of static mixers available for Polyurea mixing. The choice of mixer depends on the specific requirements of the application, including viscosity, flow rate, and mixing precision.

How to Choose the Right Static Mixer for Polyurea

Choosing the right static mixer for your Polyurea application is crucial to ensure optimal mixing performance and product quality. Here are some key factors to consider when selecting a static mixer:

1. Viscosity of Polyurea

The viscosity of the Polyurea material plays a significant role in determining the type of static mixer needed. For low-viscosity materials, a mixer with fewer mixing elements and larger flow channels may be suitable, while high-viscosity materials may require a mixer with more elements and smaller channels to achieve thorough mixing.

2. Flow Rate

The flow rate of the Polyurea material will determine the size of the static mixer required. Higher flow rates may necessitate a larger diameter mixer with longer mixing elements to ensure adequate mixing within the given time frame.

3. Mixing Precision

The level of mixing precision required for your application will influence the choice of static mixer. For applications where precise mixing is critical, such as in coatings or adhesives, a mixer with more mixing elements and a higher level of turbulence may be necessary.

4. Material Compatibility

It’s important to ensure that the static mixer is compatible with the Polyurea material being used. Some materials may react with certain mixer materials or coatings, leading to contamination or degradation of the final product.

5. Operating Conditions

Consider the operating conditions of your application, such as temperature and pressure, when selecting a static mixer. Some mixers may be better suited for high-temperature or high-pressure environments, while others may be more suitable for ambient conditions.

6. Budget and Cost Considerations

Finally, consider your budget and cost constraints when choosing a static mixer. While higher-end mixers may offer more advanced features and performance, they may also come at a higher cost. Evaluate the cost-effectiveness of the mixer based on your specific application requirements.

By considering these factors, you can select the right static mixer for your Polyurea application, ensuring efficient mixing and high-quality end products.

Installation and Maintenance of Static Mixers for Polyurea

Proper installation and maintenance of static mixers are essential for ensuring optimal performance and longevity. Here are some key tips for installing and maintaining static mixers used in Polyurea applications:

Installation Tips:

Positioning: Install the static mixer in a straight section of the pipeline, away from elbows or other obstructions that could disrupt the flow.

Orientation: Ensure that the static mixer is installed in the correct orientation, with the flow direction indicated by the arrow on the mixer.

Support: Provide adequate support for the mixer to prevent excessive vibration or movement during operation.

Alignment: Align the mixer properly with the piping system to ensure smooth flow and prevent leaks.

Maintenance Tips:

Regular Inspection: Periodically inspect the static mixer for signs of wear or damage, such as corrosion or erosion.

Cleaning: Clean the mixer regularly to remove any buildup or residue that could affect mixing performance. Use a suitable solvent or cleaning agent recommended by the mixer manufacturer.

Replacement of Elements: If the mixing elements become worn or damaged, replace them promptly to maintain optimal mixing efficiency.

Avoid Overloading: Avoid exceeding the maximum flow rate or pressure rating of the mixer, as this could lead to premature failure.

Safety Precautions:

Lockout/Tagout: Follow proper lockout/tagout procedures when installing or servicing the mixer to prevent accidental startup.

Personal Protective Equipment (PPE): Wear appropriate PPE, such as gloves and safety glasses, when handling Polyurea or performing maintenance on the mixer.

Ventilation: Ensure adequate ventilation in the area where the mixer is installed to prevent the buildup of fumes or vapors from the Polyurea.

By following these installation and maintenance tips, you can ensure that your static mixer operates efficiently and reliably, providing consistent mixing performance for your Polyurea applications.

Common Issues and Troubleshooting of Static Mixers for Polyurea

While static mixers are known for their reliability, they can encounter issues that affect their performance. Here are some common problems associated with static mixers used in Polyurea applications and how to troubleshoot them:

1. Poor Mixing Efficiency

Cause: This can be caused by improper installation, incorrect mixer size or type, or worn-out mixing elements.

Troubleshooting: Ensure the mixer is installed correctly and is the appropriate size for the flow rate and viscosity of the Polyurea. Replace any worn or damaged mixing elements.

2. Material Buildup or Clogging

Cause: Buildup of Polyurea material or contaminants within the mixer.

Troubleshooting: Clean the mixer regularly using a suitable solvent or cleaning agent to remove any buildup. Consider using a purge material to flush out the mixer.

3. Leaks or Sealing Issues

Cause: Improper sealing or damage to the mixer or piping.

Troubleshooting: Check for leaks and ensure all connections are properly sealed. Replace any damaged seals or components.

4. Flow Rate Variations

Cause: Changes in flow rate or pressure can affect the mixing efficiency.

Troubleshooting: Ensure the mixer is rated for the operating conditions and adjust the flow rate and pressure as needed.

5. Mixer Damage

Cause: Excessive wear, corrosion, or mechanical damage.

Troubleshooting: Inspect the mixer regularly for signs of damage and replace any worn or damaged parts. Consider upgrading to a more durable mixer if damage is a recurring issue.

6. Contamination

Cause: Introduction of foreign materials or contaminants into the Polyurea.

Troubleshooting: Maintain a clean environment and use clean materials to prevent contamination. Consider using filters or screens to remove contaminants from the material before it enters the mixer.

By addressing these common issues and following the troubleshooting tips, you can ensure that your static mixer operates efficiently and reliably, providing consistent mixing performance for your Polyurea applications.