The History of Static Mixing Nozzles

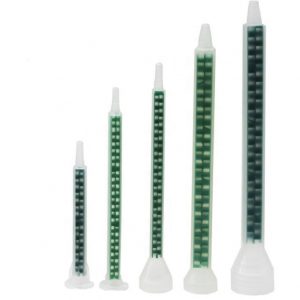

In the 1960s, the development of helical elements marked a significant milestone in the evolution of static mixing technology. These elements were designed to be inserted into pipelines or nozzles, featuring carefully engineered twists and turns.