Choosing the right mixing nozzle for two-part epoxy adhesives and coatings is critical for achieving a strong and durable bond. There are several types of mixing nozzles available, each designed for a specific application. This blog will go over how to choose the right epoxy mixing nozzle for your application.

Consider the Epoxy Type

The first factor to consider when selecting an epoxy mixing nozzle is the type of epoxy being used. The viscosity of various epoxies varies, and the mixing nozzle should be selected accordingly. A low viscosity epoxy, for example, may require a different mixing nozzle than a high viscosity epoxy. When selecting the appropriate mixing nozzle for the specific type of epoxy, it is critical to consult the manufacturer’s recommendations.

Determine the Mixing Ratio

The mixing ratio of the epoxy is also important in selecting the right mixing nozzle. The mixing ratio determines how much of each epoxy component is required to achieve the desired bond strength. The mixing nozzle should be chosen based on the mixing ratio of the epoxy. Some mixing nozzles are made for a 1:1 mixing ratio, whereas others are made for a 2:1 mixing ratio.

Consider the Application

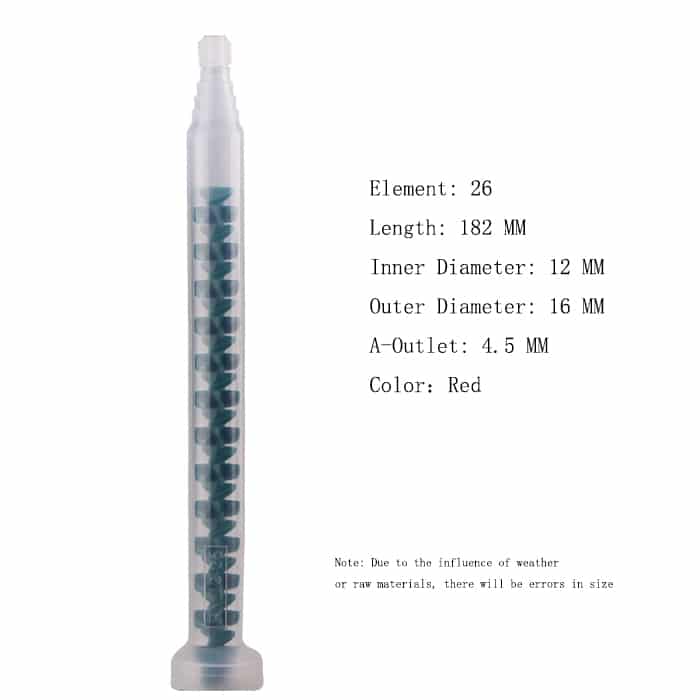

The application method is another factor to consider when selecting an epoxy mixing nozzle. The mixing nozzle must be compatible with the dispensing equipment, which could be a manual gun or a pneumatic dispenser. The size and shape of the mixing nozzle should also be considered because they influence the flow rate and coverage area. A longer mixing nozzle, for example, may be required for difficult-to-reach areas, whereas a shorter mixing nozzle may be appropriate for smaller areas.

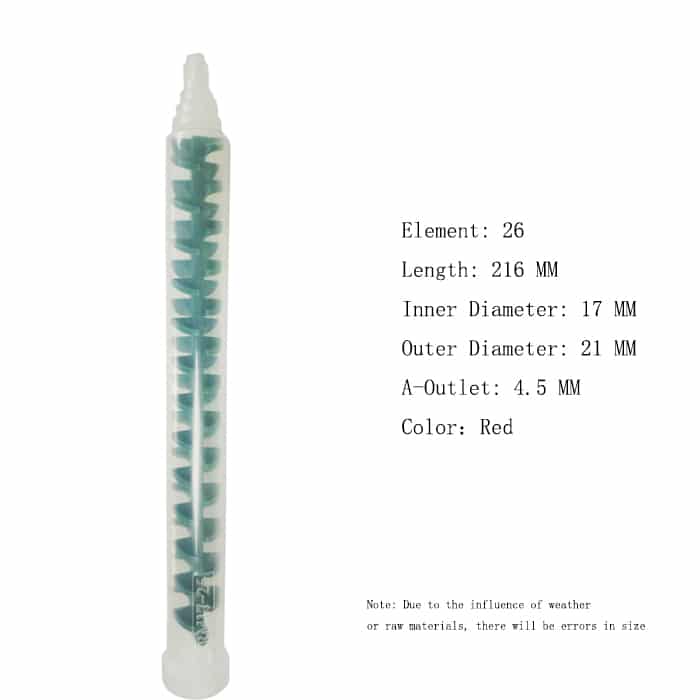

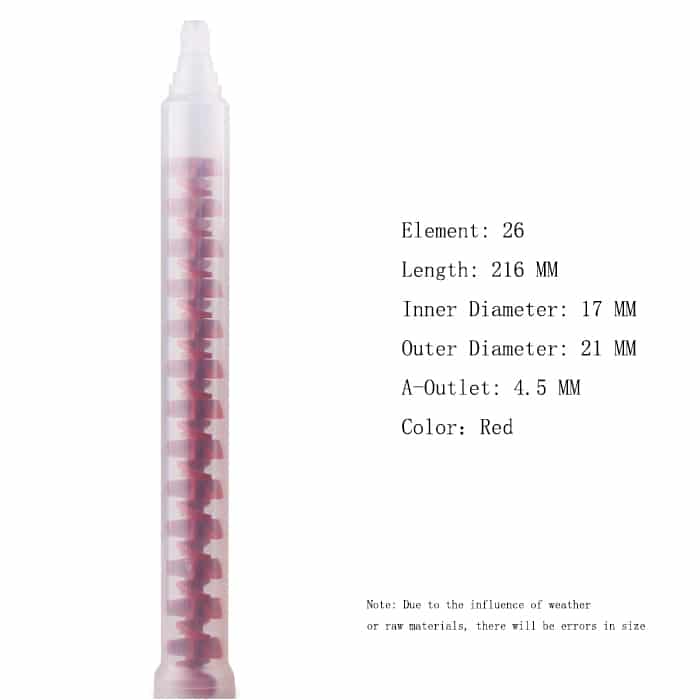

Check the Mixing Element

The nozzle’s mixing element is in charge of ensuring that the epoxy is mixed evenly and consistently. The mixing quality can be affected by the shape, size, and number of elements in the nozzle. Some mixing nozzles use static mixing elements to mix the components, while others use dynamic mixing elements to create turbulence to mix the components. To ensure that the epoxy is thoroughly mixed, select a mixing nozzle with the appropriate mixing element.

Choose the Material

When selecting the right nozzle, the material of the mixing nozzle is also an important factor to consider. Mixing nozzles can be made of a variety of materials, including polypropylene, nylon, and polyethylene. The material should be chosen based on its compatibility with the epoxy and its intended use environment. A mixing nozzle made of polypropylene, for example, may be appropriate for a chemical-resistant application, whereas a mixing nozzle made of nylon may be appropriate for a high-temperature application.

Cost Assessment

Finally, when selecting the right nozzle, the cost of the mixing nozzle should be considered. The price is determined by the type, size, and material of the nozzle. While it may be tempting to choose a less expensive mixing nozzle, keep in mind that the quality of the mixing nozzle can affect the quality of the bond. Purchasing a high-quality mixing nozzle may result in a stronger and more durable bond, saving time and money in the long run.

Conclusion

In conclusion, choosing the right epoxy mixing nozzle need to consider the type of epoxy, mixing ratio, application method, mixing element, material, and cost. If you’re not sure which nozzle is suitable for your application, then you can consult the manufacturer’s recommendations and follow best practices for using and disposing of the mixing nozzle to ensure the best results.