Two-part epoxy adhesives are used in a variety of applications, ranging from bonding metals and plastics to repairing cracks and gaps in wood and concrete. To ensure that the two components of the epoxy are properly mixed, a mixing nozzle is used. The mixing nozzle is designed to combine the two components of the epoxy as it is dispensed, creating a uniform mixture that can be applied to the surface. In this blog post, we will discuss the ins and outs of two-part epoxy mixing nozzles, including their features, benefits, and how to choose the right one for your needs.

What are Two-Part Epoxy Mixing Nozzles?

Two-part epoxy mixing nozzles are designed to combine the two components of a two-part epoxy as it is dispensed. The two components of the epoxy are typically stored in separate cartridges, with the mixing nozzle attached to the end of the cartridge. When the two components are dispensed through the mixing nozzle, they are thoroughly mixed, ensuring that the epoxy is properly combined and ready for use.

How Do Two-Part Epoxy Mixing Nozzles Work?

Two-part epoxy mixing nozzles work by creating a turbulent flow of the two components of the epoxy as they are dispensed. This turbulence helps to thoroughly mix the two components of the epoxy, ensuring that they are properly combined and ready for use. The mixing nozzle typically has a series of ridges or steps that help to create this turbulence, breaking up any clumps or lumps in the epoxy as it is dispensed.

Features of Two-Part Epoxy Mixing Nozzles

There are several key features of two-part epoxy mixing nozzles that are important to consider when choosing the right mixing nozzle for your needs. These features include:

-

Length:

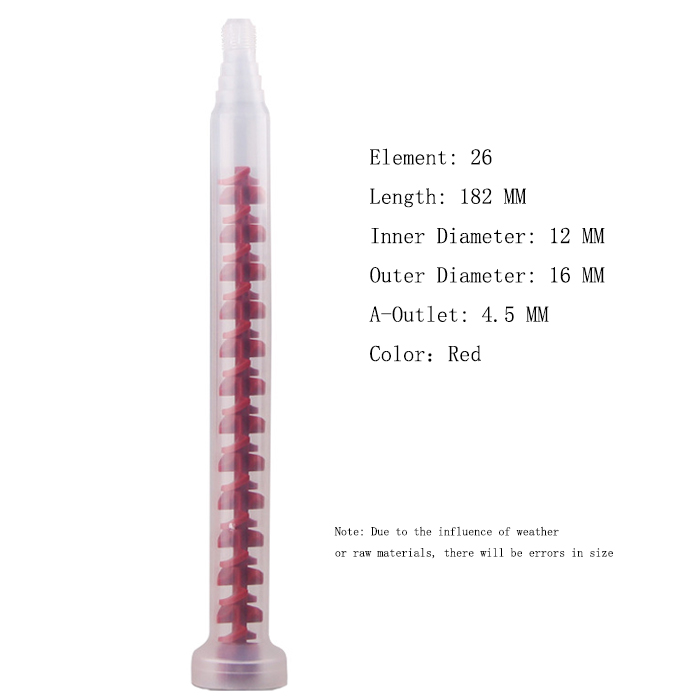

The length of the mixing nozzle can vary, with some nozzles measuring just a few inches and others measuring several feet. The length of the nozzle will depend on the application, with longer nozzles typically used for more complex or hard-to-reach areas.

-

Mixing Ratio:

The mixing ratio of the epoxy adhesive will determine the type of mixing nozzle that is required. Different mixing ratios require different types of nozzles, with some requiring a larger or smaller opening to ensure proper mixing.

-

Diameter:

The diameter of the mixing nozzle can also vary, with larger diameters typically used for higher viscosity epoxies and smaller diameters used for lower viscosity epoxies.

-

Type:

There are several different types of mixing nozzles available, including stepped, helical, bell, quadro, and spray mixing nozzles. Each type of nozzle has its own unique features and benefits, which we will discuss in more detail in the next section.

Benefits of Using Two-Part Epoxy Mixing Nozzles

There are several benefits to using two-part epoxy mixing nozzles, including:

-

Consistent Mixing:

Two-part epoxy mixing nozzles ensure that the two components of the epoxy are consistently and thoroughly mixed, ensuring that the adhesive has the required strength and properties.

-

Reduced Waste:

Two-part epoxy mixing nozzles help to reduce waste by ensuring that all of the epoxy is dispensed from the cartridge. This can help to save money and reduce environmental impact.

-

Improved Productivity:

Two-part epoxy mixing nozzles can help to improve productivity by reducing the time required to mix the two components of the epoxy. This can help to increase efficiency and reduce labor costs.

-

Improved Quality:

Two-part epoxy mixing nozzles help to ensure that the epoxy adhesive is of consistent quality, improving the overall quality of the finished product.

How to Choose the Right Two-Part Epoxy Mixing Nozzle

Choosing the right two-part epoxy mixing nozzle can be a daunting task, given the wide variety of options available. However, by considering the application, the mixing ratio, and the viscosity of the epoxy adhesive, it is possible to choose the right mixing nozzle for your needs. Some key factors to consider when choosing a mixing nozzle include:

-

Application:

The application of the epoxy adhesive will determine the length, diameter, and type of mixing nozzle required. For example, a longer nozzle may be required for hard-to-reach areas, while a wider diameter may be required for higher viscosity epoxies.

-

Mixing Ratio:

The mixing ratio of the epoxy adhesive will determine the type of mixing nozzle required. Different mixing ratios require different types of nozzles, with some requiring a larger or smaller opening to ensure proper mixing.

-

Viscosity:

The viscosity of the epoxy adhesive will also determine the type of mixing nozzle required. Higher viscosity epoxies may require a wider diameter nozzle, while lower viscosity epoxies may require a narrower diameter nozzle.

-

Compatibility:

It is important to ensure that the mixing nozzle is compatible with the cartridge and dispensing system being used. Not all mixing nozzles are compatible with all cartridges and dispensing systems.

Tips for Using Two-Part Epoxy Mixing Nozzles

While two-part epoxy mixing nozzles are designed to be easy to use, there are a few tips that can help you get the most out of your mixing nozzles:

- Make sure the cartridge is properly inserted: Before you attach the mixing nozzle, make sure the cartridge is properly inserted into the dispensing gun. This will ensure that the epoxy is dispensed properly and that the mixing nozzle fits securely onto the cartridge.

- Dispense a small amount of epoxy before applying: Before you apply the epoxy to your project, dispense a small amount of epoxy onto a scrap piece of cardboard or other surface. This will help to ensure that the two components are properly mixed and that the epoxy is flowing smoothly.

- Use the right size mixing nozzle: Make sure you choose the right size mixing nozzle for your application. A larger nozzle may be required for larger projects, while a smaller nozzle may be needed for smaller, more precise applications.

- Store unused mixing nozzles properly: If you have unused mixing nozzles, store them in a dry, cool place. This will help to ensure that they remain clean and ready for use when needed.

- Use mixing nozzles promptly: Once you attach a mixing nozzle to the cartridge and push it, two-part epoxy begins to harden as soon as the two components are mixed, so be sure to use the epoxy promptly after attaching the mixing nozzle.

By following these tips, you can ensure that your two-part epoxy mixing nozzles perform their best and that your epoxy projects turn out great.

Conclusion

In conclusion, two-part epoxy mixing nozzles are a popular and effective tool for bonding and sealing applications. These nozzles offer an easy and efficient way to dispense and mix two-part epoxy while minimizing waste and mess. By understanding the different types of mixing nozzles available and the applications they are best suited for, you can choose the right nozzle for your project and achieve optimal results.