Tips for Buying Epoxy Mixing Nozzles

In this guide, we’ll explore essential tips for buying epoxy mixing nozzles to help you make informed decisions and elevate your epoxy projects.

The following are selected blog posts about our products. If you do not find the information you need, you can contact us and we will get back to you within 24 hours.

In this guide, we’ll explore essential tips for buying epoxy mixing nozzles to help you make informed decisions and elevate your epoxy projects.

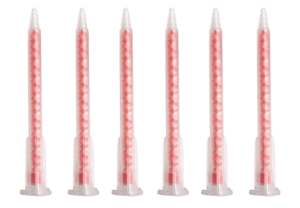

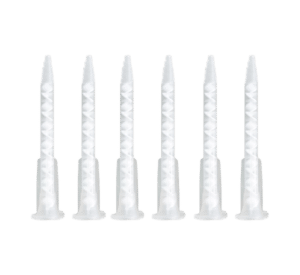

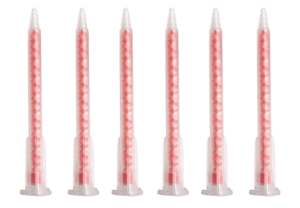

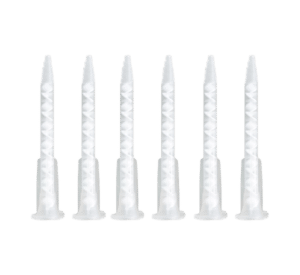

These static mixing nozzles are designed with internal elements that aid in thorough mixing of resin and hardener while minimizing the introduction of air.

Here at Btektech, we take pride in our commitment to excellence, delivering top-quality plastic syringe barrels tailored to meet diverse adhesive application needs.

Begin by separating the mixing nozzle from the dual cartridge assembly. Evaluate the extent of epoxy residue within the cartridge and nozzle.

As winter sets in, working with dual cartridges for adhesives or sealants can present unique challenges due to colder temperatures affecting their functionality.

Our comprehensive range of dispensing needles, epoxy mixing nozzles, and syringe barrels epitomizes innovation and precision in adhesive application.

Keep your epoxy cartridges and mixing nozzles in a temperature-controlled room (around 70°F/21°C) for a few hours before use to maintain their ideal viscosity.

The primary function of an epoxy mixing nozzle tip is to facilitate the thorough blending of two-part epoxy resins.

The functionality of epoxy mixing nozzles is rooted in their intricate design elements, meticulously engineered to facilitate the proper blending of epoxy components.

Here’s a closer look at some common dispensing tools used for adhesives:

Cracking of epoxy mixing nozzles is often a result of excessive pressure buildup within the nozzle during the mixing and application process.

At the crux of their brilliance lies the ability of epoxy mixing nozzles to finely calibrate the dispensing ratio of adhesive components, thereby minimizing waste.

Address: Room 1305,

Tiandu Building,

No. 211 Changjiang Road,

Huqiu District,

Suzhou, Jiangsu,

China

Tel: +8618706202541

Emails: info@btektech.com