Mixing adhesives is a crucial part of many industrial and DIY processes. Achieving a consistent and thorough mix of adhesive components is essential for ensuring the adhesive’s effectiveness and longevity. One effective tool for achieving this is a static mixing nozzle. In this blog post, we will explore the circumstances in which you might need a static mixing nozzle to mix adhesives.

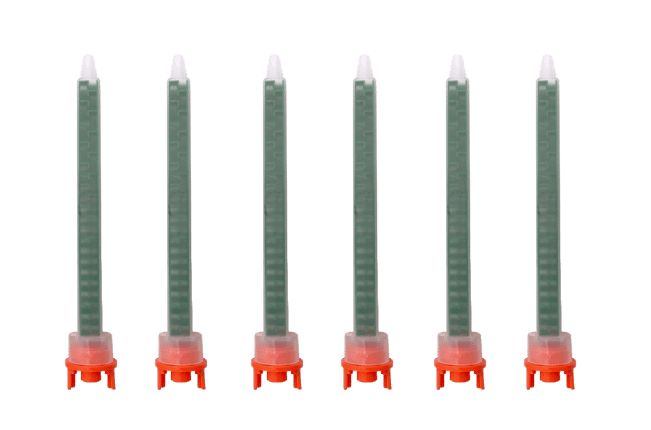

What Is The Static Mixing Nozzle?

The static mixing nozzle, often referred to as a motionless mixer or a motionless nozzle, is a specialized tool designed to mix two or more components of an adhesive as they pass through it. Unlike traditional methods that rely on manual or mechanical mixing, static mixing nozzles use a series of stationary elements within the nozzle to promote thorough blending. This process results in a homogeneous mixture and eliminates the need for manual stirring, reducing labor costs and minimizing waste.

Now, let’s dive into the scenarios in which a static mixing nozzle becomes a valuable asset:

Two-Component Adhesives

Two-component adhesives, commonly known as 2K adhesives, consist of a resin and a hardener that must be mixed in precise proportions to achieve the desired adhesive properties. A static mixing nozzle is indispensable in this case, ensuring that the components are evenly mixed without variation, which is often challenging to achieve with manual methods.

Fast-Setting Adhesives

Adhesives that cure rapidly can pose a challenge when mixed manually because time is of the essence. A static mixing nozzle provides a swift and efficient way to blend the components while maintaining accuracy and speed, reducing the risk of premature curing.

High-Viscosity Adhesives

High-viscosity adhesives can be difficult to mix evenly without a static mixing nozzle due to their thick consistency. These nozzles are designed to handle such adhesives effectively, ensuring that both components are thoroughly combined, resulting in a consistent final product.

Precision Bonding Applications

In industries where precision is paramount, such as aerospace and medical equipment manufacturing, a static mixing nozzle guarantees that the adhesive components are mixed uniformly. This is essential for reliable bonds, where any inconsistencies can lead to catastrophic failures.

Cost and Waste Reduction

Static mixing nozzles are a cost-effective solution. They reduce labor costs associated with manual mixing, minimize adhesive waste due to improper blending, and improve the overall efficiency of the adhesive application process.

Consistency and Quality

The static mixing nozzle ensures that every batch of adhesive is consistent in its properties. This consistency translates to high-quality products and fewer defects, making it particularly valuable in industries with stringent quality control standards.

Conclusion

In summary, a static mixing nozzle is an essential tool in various adhesive application scenarios. Whether you are working with two-component adhesives, fast-setting materials, high-viscosity substances, or require precision and consistency, a static mixing nozzle can significantly improve your process. Not only does it enhance the quality of your adhesive bonds, but it also reduces costs and waste, making it a worthwhile investment for a wide range of applications. So, when do you need a static mixing nozzle to mix adhesives? The answer is, more often than you might think, to ensure optimal results and efficiency in your adhesive projects.