Plastic Static Mixer vs. Metal Static Mixer

Plastic mixers offer excellent chemical resistance and cost-effectiveness, making them suitable for moderate operating conditions.

The following are selected blog posts about our products. If you do not find the information you need, you can contact us and we will get back to you within 24 hours.

Plastic mixers offer excellent chemical resistance and cost-effectiveness, making them suitable for moderate operating conditions.

Over-mixing epoxy can lead to various problems, including reduced working time, increased heat generation, air bubble formation, and weakened bond strength.

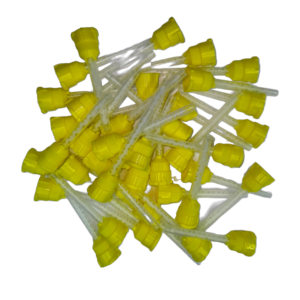

When it comes to mixing nozzles, they can generally be categorized as either disposable or reusable. Disposable nozzles are intended for single-use applications and are typically made of plastic.

Plastic mixing nozzles offer a superior mixing solution for polyurethane adhesives, ensuring consistent and reliable bonding performance.

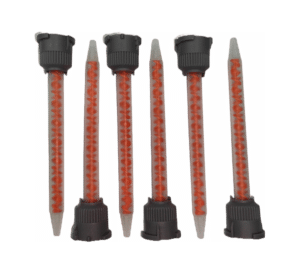

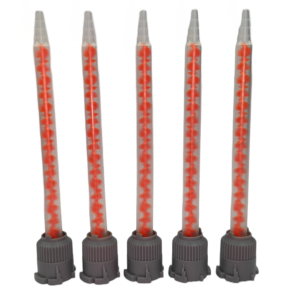

Dual-component adhesive mixing nozzles are specially designed tools used in adhesive application processes.

Epoxy mixing nozzles are specifically designed for combining epoxy resin and hardener. These nozzles have two separate channels that merge into a mixing chamber, ensuring precise blending.

In this article, we will explore the world of dual-component adhesives, covering their definition, types, and the proper use of mixing nozzles.

Epoxy mixing tubes have proven to be invaluable assets in industrial manufacturing, offering enhanced efficiency, precision, and reliability in adhesive bonding.

Epoxy mixing nozzles offer convenience, accurate mixing ratios, and are suitable for smaller applications. Epoxy mixing paddles provide versatility, better control, and reusability, making them ideal for larger projects.

In this article, we will explore the functions, types, benefits, and applications of dispensing mixing nozzles.

Helical mixing nozzles are engineered with a helical design, consisting of twisted or spiral-shaped elements within the nozzle.

This article delves into the intriguing history of these indispensable tools, tracing their evolution from humble beginnings to the sophisticated designs of today.

Address: Room 1305,

Tiandu Building,

No. 211 Changjiang Road,

Huqiu District,

Suzhou, Jiangsu,

China

Tel: +8618706202541

Emails: info@btektech.com