Introduction

In the intricate world of precision assembly, success often hinges on the smallest details. Among the most critical yet frequently overlooked components is the humble dispensing tip. Choosing the correct needle or nozzle can help unlock significant gains in manufacturing efficiency, product quality, and cost savings.

Why are there so many types of dispense tips? The answer lies in the vast diversity of fluids—from thick greases and pourable adhesives to thin solvents—each with unique properties and application requirements. Selecting the wrong one can lead to increased rework, higher rejection rates, and extended cycle times, ultimately compromising part quality and production efficiency.

This ultimate guide is designed to empower you with the knowledge to make informed decisions. We will explore 11 essential types of dispensing tips, detailing how their specific designs—from chemical-resistant builds to angled and flexible forms—solve real-world application challenges. Our goal is to help you streamline your process, enhance precision, and achieve the consistent, high-quality results your business depends on.

We also understand that every application is unique—which is why we offer custom solutions tailored to your specific needs. Whether you require a special length, material, or tip design, our team is ready to collaborate and deliver exactly what your process demands.

- If you have any questions about our products or services, or would like to request a free sample, please contact us—we’re here to help.

Angled Dispensing Tips – Precision Dispensing for Hard-to-Reach Areas

When your application demands accuracy in tight spaces or hard-to-reach areas, Angled Syringe Dispensing Tips are the ultimate solution. Made from stainless-steel needle with a polypropylene (PP) or metal hub, feature precise 45° and 90° angles that allow operators to easily navigate around components and deliver materials exactly where they’re needed.

Built upon a standard straight needle with an additional bending process, these components are indispensable for complex or confined dispensing tasks where straight needles simply cannot perform effectively. The 45° version provides excellent control for applications requiring angled delivery, while the 90° option excels in areas with extremely limited access.

Key Advantages of Angled Dispensing Tips

- Enhanced access to confined or obstructed areas

- Reduced material waste and lower contamination risk

- Improved precision and consistent performance

Applications and Benefits for Confined-Area Dispensing

Angled Tips are indispensable in scenarios where components create deep shadows or tight spaces on a board. In electronics manufacturing, they allow for precise adhesive deposition around tall connectors or under shielded components without requiring tooling changes. The automotive industry leverages them to apply sealants and lubricants into multi-layered assembly gaps. By delivering material directly to the target area, they not only accelerate production cycles but also significantly lower the risk of costly overspray and cross-contamination, ensuring a cleaner and more reliable assembly line.

Blunt Tip Needle – Safe, Versatile, and Precision-Engineered

Blunt Tip Needles are the go-to choice for a wide range of industrial and laboratory applications when safety and accuracy are top priorities. These needles feature a rounded, non-sharp tip that prevents accidental punctures and protects sensitive substrates from damage.

Blunt needles are highly versatile and seamlessly compatible with syringe cartridges, valves, and mixing tubes, allowing for easy integration into both manual and automated systems. Available in a variety of materials, these precision-engineered components are suitable for applying adhesives, solvents, lubricants, inks, and other liquids.

Key Advantages of Blunt Tip Needle

- Safe design with rounded, non-sharp tip prevents damage and injury

- Broad material compatibility for adhesives, solvents, lubricants, and inks

- Available in multiple gauges and lengths to meet diverse application needs

Applications and Benefits for Safe and Non-Damaging Dispensing

The non-sharp design of Blunt Tip Needles makes them invaluable in assembly lines where accidental scratches or operator safety are pressing concerns. In electronics manufacturing, they are extensively used for applying conformal coatings or potting compounds onto finished PCBs, as the safe tip glides over delicate solder joints and components without causing harm. Similarly, in automotive assembly and maintenance, they allow for the controlled application of sealants and lubricants in tight spaces where a sharp tip could damage wiring or pose a safety hazard. This combination of safety and precision minimizes defects and downtime, making them a reliable, cost-effective solution for high-quality production

At Btektech, we supply both standard and custom configurations with fast turnaround times—ensuring you receive the right one for your system without production delays.

Brush Dispensing Tips – Smooth, Controlled Application for Low-Viscosity Liquids

Brush Dispensing Tips are specifically designed for low-viscosity materials such as lubricants, activators, adhesives, oils, and solvents. Their greatest strength lies in their ability to spread, coat, or dab these liquids evenly and efficiently. Whether you’re applying a thin layer of flux on a circuit board, coating a mechanical bearing with lubricant, or evenly distributing a conductive adhesive, the brush tip ensures precision without drips or waste. But Brush tips are not suitable for high-viscosity glues or pastes, as these can clog the bristles.

Btektech Brush Dispensing Tips feature wear-resistant nylon bristles and a universal Luer lock connection, ensuring a secure, leak-free fit with most dispensing systems. Available in a wide range of shapes, sizes, bristle stiffness, and colors, these tips provide a versatile and cost-effective solution for achieving precision and consistency.

Key Advantages of Brush Dispensing Tips

· Enhanced precision application with soft, fine-grade nylon bristles

· Durable and oil-resistant construction for continuous industrial use

· Universal Luer lock compatibility and versatile bristle options

Applications and Benefits for Uniform Coating

Brush Dispensing Tips excel in transforming a simple dispensing action into a precise coating process. In precision electronics assembly, the gentle bristles safely apply lubricants or fluxes onto sensitive connectors and PCB surfaces, preventing scratches while guaranteeing a uniform film thickness. For automotive maintenance and repair, the robust bristle structure is ideal for applying protective coatings or sealants onto irregular metal or composite parts, ensuring complete coverage in tough environments. This capability to combine fluid placement with immediate spreading significantly reduces material waste, improves finish quality, and boosts efficiency in both manual and automated workflows.

Flexible Dispensing Tips – Accurate Application in Hard-to-Reach Areas

Flexible Dispensing Tips are the ideal solution for achieving precision in confined spaces and on sensitive surfaces where rigid needles pose a risk. Engineered from high-quality polypropylene (PP), these tips can be easily bent and maneuvered around obstacles, ensuring accurate fluid placement in tight or angled areas without causing surface damage.

Btektech offers both glue-bonded for general use and one-piece integrated (P-Series) with chemical resistance for harsher fluids. Their inherent flexibility and ability to be trimmed to the exact required length make them uniquely adaptable to complex dispensing challenges.

Key Advantages of Flexible Dispensing Tips

- Exceptional flexibility for hard-to-reach or irregular surfaces

- Corrosion-resistant PP/PE construction for chemical compatibility

- Non-marring design protects delicate substrates

- Customizable length and angle – can be cut to fit specific tasks

Applications and Benefits for Dispensing in Hard-to-Reach Areas

These tips excel in situations where a rigid tool would be impractical or damaging. In PCB assembly, they safely navigate around fragile components and tall connectors to dispense flux or UV adhesives, preventing costly damage and rework. For medical device and lab equipment assembly, the flexible body allows for precise micro-volume dispensing of lubricants onto intricate, curved plastic parts, ensuring complete coverage without contamination. By providing a safe and adaptable way to reach deep grooves or hidden channels, they enhance process reliability and protect product integrity across advanced manufacturing lines.

Oval Dispensing Tips – Flat, Precise Beads for Specialty Applications

When your application requires a flat, consistent bead of high-viscosity material rather than a traditional round dot, Oval Dispensing Tips are the ideal solution. Precision-engineered with an elongated oval orifice, these tips deposit a smooth, flat ribbon of pastes, gels, and sealants, ensuring uniform coverage over broader bonding areas in a single pass.

Btektech offers these tips in both a cost-effective Polypropylene (PP) Hub with stainless steel needle and a fully metal construction with riveted joint for superior strength. For specialized needs, our standard needles can also be custom-machined into oval versions to meet unique application requirements.

Key Advantages of Oval Dispensing Tips

· Flat ribbon output for wide, consistent coverage of thick fluids

· PP and all-metal options for different strength and cost needs

· Custom-machinable from standard needles for specialized tasks

Applications and Benefits for Seam Sealing and Gasketing

The unique flat bead profile of oval tips is a game-changer for applications where area coverage is more critical than a dot or line. In electronics, they are perfect for efficiently spreading thermal interface materials or gap fillers across large components, enhancing heat dissipation without air gaps. Within industrial equipment assembly, the oval orifice enables the precise deposition of lubricants and heavy-duty sealants in a flat pattern onto gears and fasteners, ensuring complete coverage that reduces wear and prevents loosening. This capability to form a uniform, wide bead in one step significantly accelerates production, minimizes material waste, and guarantees a more reliable bond or seal.

PTFE Tips – Precision and Chemical Resistance for Demanding Applications

PTFE-lined Dispensing Tips are engineered to excel in the most challenging chemical environments, setting the benchmark for clog-resistant performance and precision. The unique design integrates a stainless steel outer cannula with an inner smooth PTFE lining that extends approximately 3mm beyond the needle, forming a dedicated non-stick outlet zone.

This construction is specifically optimized for low-viscosity, reactive fluids like cyanoacrylates (instant adhesives) and anaerobics, which are prone to curing upon contact with metal surfaces. The result is unparalleled anti-clogging performance and consistent, reliable fluid dispensing.

Key Advantages of PTFE Tips

- Superior chemical resistance, ideal for aggressive adhesives like cyanoacrylates

- Non-stick properties that prevent material buildup and blockages

- Enhanced material flow for consistent, uninterrupted application

Applications and Benefits for Clog-Free Dispensing of Reactive Materials

PTFE tips are indispensable in automated and high-volume settings where downtime for clearing clogs is costly. In electronics micro-assembly, they enable the continuous and precise application of instant adhesives for component bonding without the risk of tip blockage disrupting production cycles. The automotive industry leverages them for applying sealants and adhesives on sensors and connectors, where the chemical resistance ensures fluid integrity and prevents contamination of critical parts. By guaranteeing a stable, predictable flow of even the most reactive chemicals, these tips enhance bonding quality, reduce waste, and uphold throughput in professional manufacturing workflows.

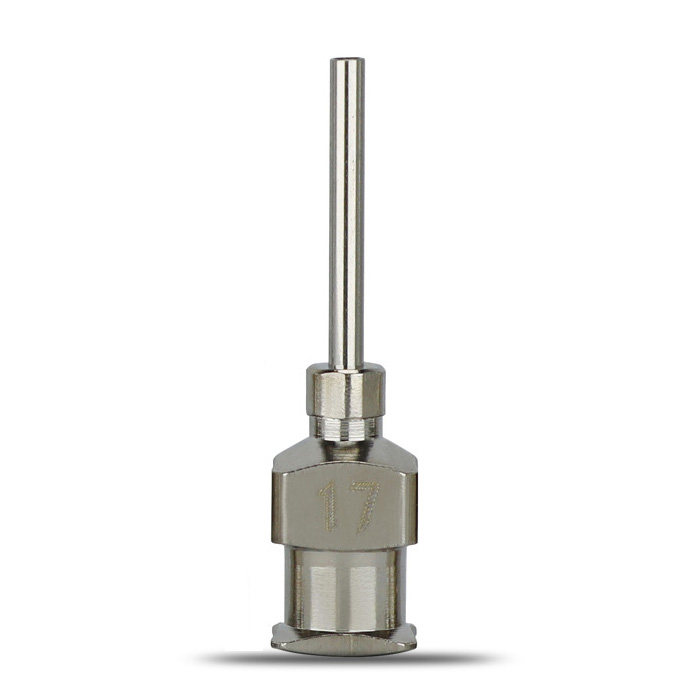

Stainless Steel Dispensing Tips – Precision and Durability for High-Speed Applications

Stainless Steel Dispensing Tips represent the premium standard for strength and precision in demanding fluid dispensing. Featuring precision-machined, burr-free stainless steel needles combined with a nickel-plated brass hub and secure Luer lock, these tips are engineered for unwavering reliability in high-speed automated production.

The full-metal, riveted construction provides exceptional mechanical strength and temperature resistance, ensuring dimensional stability and precise needle alignment even under high pressure. This makes them ideal for dispensing a wide range of demanding fluids, from adhesives and solvents to oils and activators.

Key Advantages of Stainless Steel Dispensing Tips

· Premium burr-free needles for consistent flow and dot placement

· High strength & temperature resistance with riveted metal construction

· Precise flow control for demanding fluids in automated systems

Applications and Benefits in Automated High-Throughput Production

Stainless Steel Dispensing Tips are used across a wide range of industries. In electronics assembly, their metal-on-metal design prevents interaction with sensitive substrates, ensuring pure, contamination-free application of adhesives and chemicals in SMT and PCB repair processes. The automotive sector relies on them for their resilience against harsh chemicals like activators and anaerobic adhesives, providing consistent performance in dynamic, high-temperature bonding and sealing operations. For industrial automation, their riveted design guarantees stable needle alignment and unwavering flow accuracy, which is critical for maintaining uptime and precision in robotic dispensing systems. This combination of ruggedness and precision directly translates to reduced downtime and enhanced process reliability in high-volume manufacturing.

Stainless Steel Precision Nozzle – Unmatched Accuracy for Micro-Dispensing Applications

Stainless Steel Precision Nozzles are engineered to deliver contamination-free, consistent performance in the most demanding high-accuracy industrial production environments. Featuring a polished, burr-free stainless steel tip and a precision-engineered tapered internal geometry, these nozzles provide superior flow control and long-term durability. They are available in both integrated and split designs to seamlessly fit diverse automated dispensing systems.

Advanced CNC manufacturing ensures seamless forming and mirror-polished inner walls, which are critical for handling everything from low-viscosity coatings to granular and highly viscous fluids without clogging.

Key Advantages of Stainless Steel Precision Nozzles

- Tapered nozzle design for superior flow control and material placement accuracy

- High-precision CNC manufacturing ensures clog-resistant, consistent micro-dispensing

- Reusable and easy to clean, with a high-quality finish for long-lasting use

Applications and Benefits in Semiconductor and Microelectronics Assembly

Stainless Steel Precision Nozzles are ideal for micron-level precision in electronics and semiconductor industries, such as underfilling and encapsulation of BGA packages, coating for CCD sensors, crystal resonator sealing, and LCD panel gasketing. These nozzles ensure zero material waste and highly accurate dispensing, making them invaluable for sensitive and expensive components. Thanks to their ultra-smooth interior and precise tip design, these nozzles dramatically reduce downtime and minimize the chances of clogging, improving overall production efficiency and maintaining the highest quality output in your dispensing process.

Tapered Dispensing Tips – Precision Flow Control for Clean, Drip-Free Dispensing

Tapered Dispensing Tips are designed to control the flow of viscous fluids. Their gradually narrowing design ensures smooth, controlled material output with minimal dripping and stringing, making them a superior choice for dispensing medium- to high-viscosity materials like epoxies, silicones, and solder pastes on industrial production lines.

Crafted from high-quality polypropylene, these tips offer excellent chemical resistance. For specialized needs, Btektech offer black PP versions to prevent premature curing of UV-sensitive adhesives, as well as custom ESD-safe materials to protect sensitive electronic components during assembly.

Key Advantages of Tapered Dispensing Tips

- Tapered body design ensures controlled material flow

- Excellent drip resistance, preventing excess material application.

- Highly versatile design suitable for many common materials.

Applications and Benefits for Precision Flow Control and Drip-Free Precision

These tips excel in environments where controlling bead profile and preventing mess are critical. In electronics assembly, their precise dot and line control is perfect for applying UV-cure adhesives and conductive epoxies on delicate circuits, effectively preventing overflow and protecting solder joints. Within LED and optical module production, the reduced dripping capability is crucial for tasks like LED potting and lens bonding, where excess adhesive can critically impact optical performance and alignment. For general industrial maintenance and manufacturing, their enhanced flow capacity and durability make them ideal for applying silicones and particle-filled sealants.

Aluminum Hub Dispensing Tips – Durable, Precise, and Corrosion-Resistant

Aluminum Hub Dispensing Tips are precision-engineered for durability and reliability, making them an ideal choice for a variety of industrial applications. Constructed from high-quality stainless steel needle and polypropylene (PP) hub, each unit features a robust design that connects the needle holder with a steel pipe by aluminum inlay riveting. This advanced construction eliminates the weaknesses of conventional adhesive-based needles, preventing issues like glue deterioration or chemical corrosion and greatly extending the tip’s service life.

Designed for precise and consistent material application, these tips are compatible with a wide range of substances, including greases, adhesives, and lubricants. They are particularly well-suited for soldering, bonding, coating, and SMT assembly, offering greater reliability than plastic options.

Key Advantages of Aluminum Hub Dispensing Tips:

- Corrosion-resistant construction for use with aggressive or reactive fluids

- Disposable design for easy maintenance and contamination control

- Enhanced precision and longer lifespan compared to plastic alternatives

Applications and Industry Benefits in Precision Bonding

These features make Aluminum Hub needles a reliable choice for demanding industries like electronics, automotive, aerospace, and medical device manufacturing. They excel in precision tasks—such as bonding micro-components or applying sealants—where failure is not an option. By resisting clogs and chemical corrosion, they significantly reduce downtime and waste, directly boosting productivity and cutting operational costs.

Conclusion

Navigating the world of dispensing tips is the first step toward mastering precision and efficiency in your manufacturing process. As we’ve explored, each type—from adaptable reach of Angled Dispensing Tips to the micro-dispensing accuracy of Stainless Steel Precision Nozzles—is engineered to solve a specific set of challenges, directly impacting your output quality and operational costs.

Beyond selecting the right type, quality is paramount. Inconsistent bore polishing, burrs, or flashing—often imperceptible to the naked eye—can disrupt material flow, compromise deposit consistency, and even introduce contaminants into your valuable fluids. For peak performance, it’s also crucial to consider your dispensing system as a whole. Ensuring that your tips, syringes, and barrels are designed to work in harmony is key to minimizing waste and achieving unparalleled accuracy.

At Btektech, we build this foundation of quality and compatibility into every product. Our products undergo stringent inspection to ensure they are burr-free and feature polished pathways, all produced in a controlled environment to safeguard your materials. This commitment guarantees that you can focus on innovation, not on troubleshooting your dispense process.

Ready to Optimize Your Dispensing Process? Let Btektech Be Your Guide.

Your perfect solution is within reach. Choose your path forward:

- Browse Our Product Catalog: Explore our full range of high-performance, ready-to-ship dispensing tips to find your ideal match.

- Request a Custom Solution: Have a unique application? Our technical team specializes in designing and manufacturing custom tips to meet your exact specifications.

- Get a Free Sample: Experience the Btektech difference firsthand. Contact us today to request a complimentary sample and validate the quality for yourself.

Don’t let a standard component limit your extraordinary potential. Contact Btektech now, and let’s build the precise solution your process deserves.