In the realm of adhesive applications, achieving precise and uniform mixing is essential for obtaining optimal bonding results. To simplify and streamline the mixing process, static mixing nozzles have emerged as a game-changer. These innovative tools are designed to ensure thorough blending of adhesive components, providing consistent and reliable results. In this article, we will explore the advantages and functionalities of static mixing nozzles, highlighting their crucial role in enhancing precision and performance in a wide range of adhesive applications.

Efficient and Consistent Mixing:

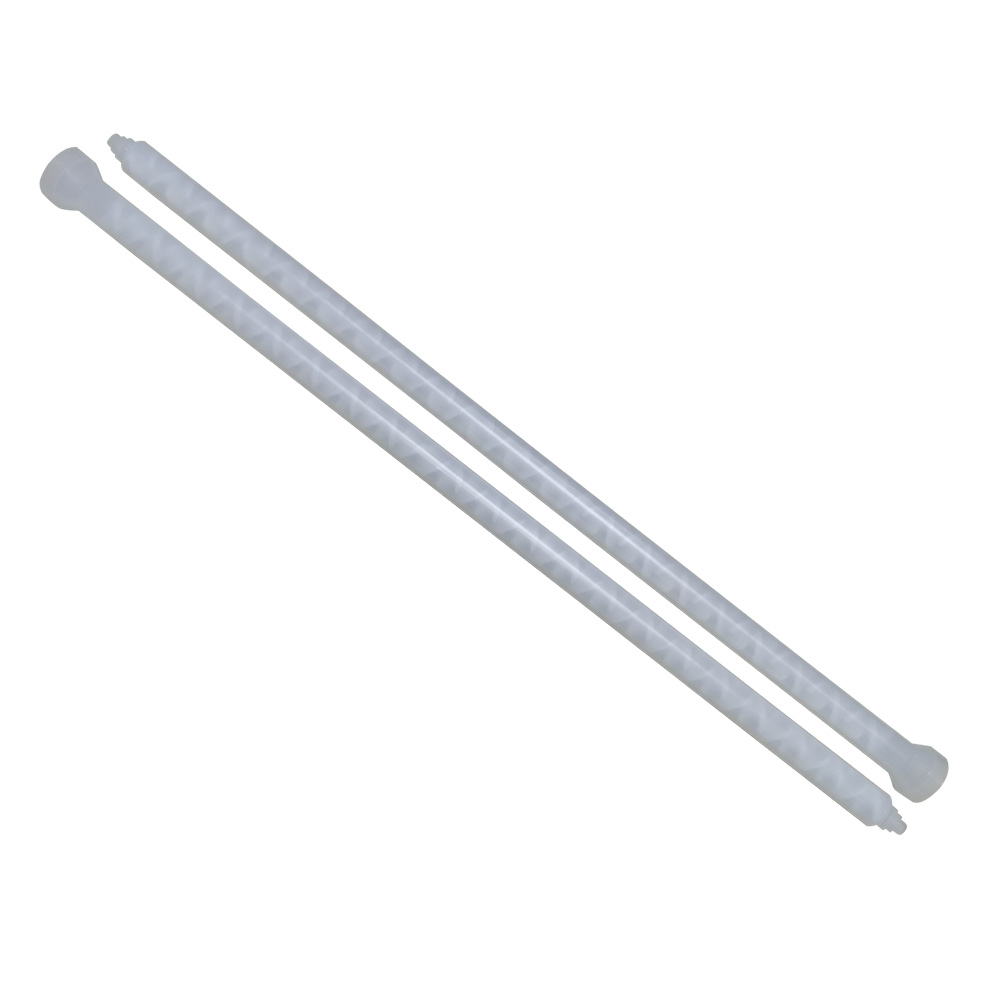

Static mixing nozzles are engineered to promote efficient and thorough mixing of two or more components of an adhesive. These nozzles feature a series of stationary elements, such as baffles or elements with geometric shapes, strategically positioned within the mixing chamber. As the adhesive passes through these elements, it undergoes repeated splitting, folding, and recombining, resulting in efficient blending. This intricate mixing process ensures that the components are uniformly distributed, eliminating the risk of inadequate mixing and producing consistent bonding performance.

Elimination of Manual Mixing:

Gone are the days of manually mixing adhesive components, which can be time-consuming and prone to human error. Static mixing nozzles eliminate the need for hand-mixing by automating the blending process. The nozzle’s design ensures that the components are mixed thoroughly as they flow through the nozzle, eliminating the possibility of inadequate or inconsistent mixing. This not only saves time but also enhances the accuracy and reliability of adhesive application.

Reduction in Waste and Cost:

Static mixing nozzles play a vital role in reducing waste and cost associated with adhesive applications. With manual mixing, excess adhesive often goes unused or dries up before it can be applied. However, static mixing nozzles provide precise control over the amount of adhesive dispensed, minimizing waste and ensuring that only the required amount is used. By reducing waste, these nozzles contribute to cost savings and maximize the efficiency of adhesive usage.

Versatility in Application:

Static mixing nozzles are highly versatile and can be utilized in various adhesive applications. They are suitable for a wide range of materials, including epoxies, silicones, urethanes, and acrylics. These nozzles are used in industries such as automotive, aerospace, construction, electronics, and more. Whether it’s bonding, sealing, potting, or encapsulating, static mixing nozzles can handle diverse adhesive applications with precision and efficiency.

Ease of Use and Maintenance:

Using static mixing nozzles is straightforward and user-friendly. They can be easily attached to adhesive cartridges or dispensing systems, making them accessible to both professionals and DIY enthusiasts. Moreover, cleaning and maintaining these nozzles are hassle-free. Many static mixing nozzles are disposable, eliminating the need for time-consuming cleaning procedures. This convenience further enhances productivity and reduces downtime.

Conclusion:

Static mixing nozzles have become indispensable tools in adhesive applications, offering numerous benefits that enhance precision, performance, and efficiency. With their ability to ensure thorough and consistent mixing, eliminate manual blending, reduce waste and cost, and cater to various adhesive materials and applications, these nozzles have revolutionized the adhesive industry. By incorporating static mixing nozzles into your adhesive processes, you can achieve reliable and uniform bonding results, saving time and resources while optimizing the quality of your work.