Industrial Automation & Precision Fluid Control

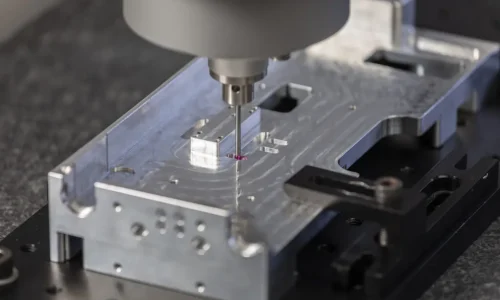

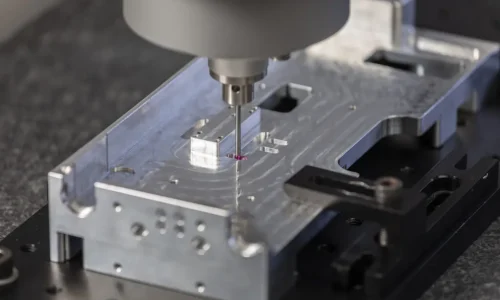

Compatible with robotic and automated dispensing systems. The all-metal riveted design ensures stable needle alignment and flow accuracy under high-pressure and elevated-temperature operations.

High-Strength, Burr-Free Precision Needles for Industrial Fluid Dispensing

Btektech Stainless Steel Dispensing Needle with Nickel Plated Brass for precision dispensing in high-speed automated production. Customizable in gauge, length, and multi-needle configurations to meet diverse industrial requirements.

Each needle is precision-machined and polished on both sides, creating a smooth, unobstructed fluid path. This ensures consistent adhesive flow, accurate dot placement, and reduced clogging in high-speed manufacturing environments.

The riveted connection between the needle and metal hub provides exceptional structural integrity, allowing reliable operation under high pressure and elevated temperatures.

The full-metal needle-to-hub construction maintains alignment and dimensional stability, ensuring precise dispensing of adhesives, solvents, oils, and activators where mechanical robustness and flow consistency are critical.

Ideal for applying adhesives and chemicals where metal contact prevents interaction with sensitive substrates. Ensures stable dispensing in SMT, PCB repair, and micro-bonding lines requiring tight control.

With excellent resistance to oils, activators, and anaerobic adhesives, stainless steel tips ensure contamination-free bonding and sealing in dynamic, high-temperature automotive environments. The durable metal hub maintains performance during continuous automated operations.

Compatible with robotic and automated dispensing systems. The all-metal riveted design ensures stable needle alignment and flow accuracy under high-pressure and elevated-temperature operations.

Explore the complete range of Btektech Stainless Steel Dispensing Tips in the table below. Each model’s part number links to its detailed specifications and pricing sheet. For a comprehensive overview of all our dispensing consumables, please contact us or download the product catalog.

| Stainless Steel Precision Nozzles | |||

|

Best For |

Industrial dispensing under pressure and heat | Micro-dispensing in automated high-precision systems | Low-viscosity, chemically aggressive fluids |

|

Core Construction |

Full stainless-steel with riveted metal hub | CNC-machined stainless-steel with tapered design |

Stainless-steel with PTFE inner lining |

|

Key Advantage |

Structural strength and alignment stability | Tapered geometry ensures precision and reusability |

Anti-clog smooth flow with chemical resistance |

| Common Applications | Adhesives, oils, activators, automated lines | Semiconductor, LED, microelectronics production |

Cyanoacrylates, reactive adhesives |

| Stainless Steel Precision Nozzles | |||

|

Best For |

Industrial dispensing under pressure and heat | Micro-dispensing in automated high-precision systems | Low-viscosity, chemically aggressive fluids |

|

Core Construction |

Full stainless-steel with riveted metal hub | CNC-machined stainless-steel with tapered design |

Stainless-steel with PTFE inner lining |

|

Key Advantage |

Structural strength and alignment stability | Tapered geometry ensures precision and reusability |

Anti-clog smooth flow with chemical resistance |

| Common Applications | Adhesives, oils, activators, automated lines | Semiconductor, LED, microelectronics production |

Cyanoacrylates, reactive adhesives |

At Btektech, we engineer custom solutions for all products related to adhesives and fluid dispensing.

Our Customization Options Include:

· Physical Attributes: Size, material, and color.

· Branding: Custom packaging and logo application.

· Functional Design: Modifications based on your requirements.

To get started, simply share your basic drawings, functional specifications, or intended usage scenarios. Our engineering team will assess feasibility and collaborate with you to develop a high-performance, reliable solution.

Partner with Btektech for Precision

From initial design to final delivery, we ensure your custom solution achieves unmatched consistency. If you have a customization need, contact us today to discuss your project.

Discover similar options and compatible equipment, accessories, and consumables that pair seamlessly with this product—helping you evaluate alternatives or integrate complementary components for consistent, reliable, and precise dispensing performance.

Yes. The smooth, burr-free interior minimizes flow resistance and clogging, ensuring consistent deposition and enhanced production quality.

Stainless steel needles are suitable for many fast-curing and reactive materials, including certain epoxies and light-curable adhesives. For standard cyanoacrylates or applications sensitive to metal contact, our PTFE-lined Tips may provide optimized anti-curing performance. Our engineering team can recommend the best solution based on your adhesive formulation and dispensing cycle.

The riveted metal needle-to-hub structure delivers high mechanical strength, dimensional stability, and precise flow control, reducing downtime and ensuring consistent performance in demanding industrial environments.

It depends on your dispensing environment:

• Nickel-plated Brass Hub: Cost-effective with moderate strength, suitable for general applications.

• Stainless Steel Hub: Provides maximum mechanical strength and elevated temperature resistance, ideal for demanding fluids.

• Aluminum Hub: Lightweight for rapid robotic movement and reduced inertia.

Btektech can advise on the best hub choice based on pressure, temperature.

Absolutely. As a direct manufacturer, Btektech offers fully customized solutions including needle gauge, extended lengths, multi-needle arrays, and tailored layouts to optimize dot precision, flow, and automation compatibility.

Need More Information?

Our experts are ready to assist

Get personalized answers for your unique requirements and use cases.

Our blog is designed to help you deepen your knowledge of fluid dispensing processes, optimize your production line, and select the best components for your specific challenges. Explore articles that connect industry insights with practical solutions.

One of the most common mistakes when using dispensing tips is selecting the wrong tip size for the application.

The material of the dispensing needle is a critical consideration, as it affects compatibility with various types of adhesives.

In this ultimate guide to dispensing tips, we will explore seven types of dispensing tips, their features, and their ideal applications.