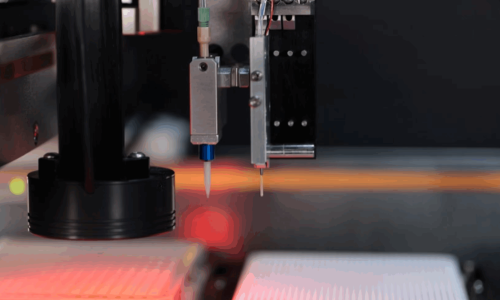

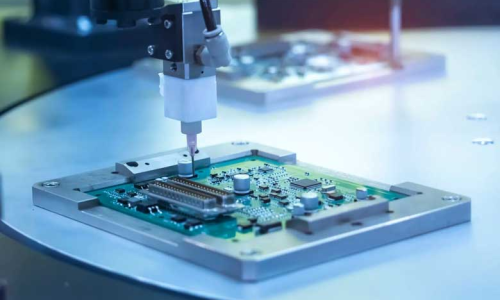

Appliance and Consumer Goods Manufacturing

Suited for bonding and sealing large surface areas in appliances, furniture, and consumer products. The consistent flat bead ensures strong adhesion and clean seams, improving both product durability and finished appearance.