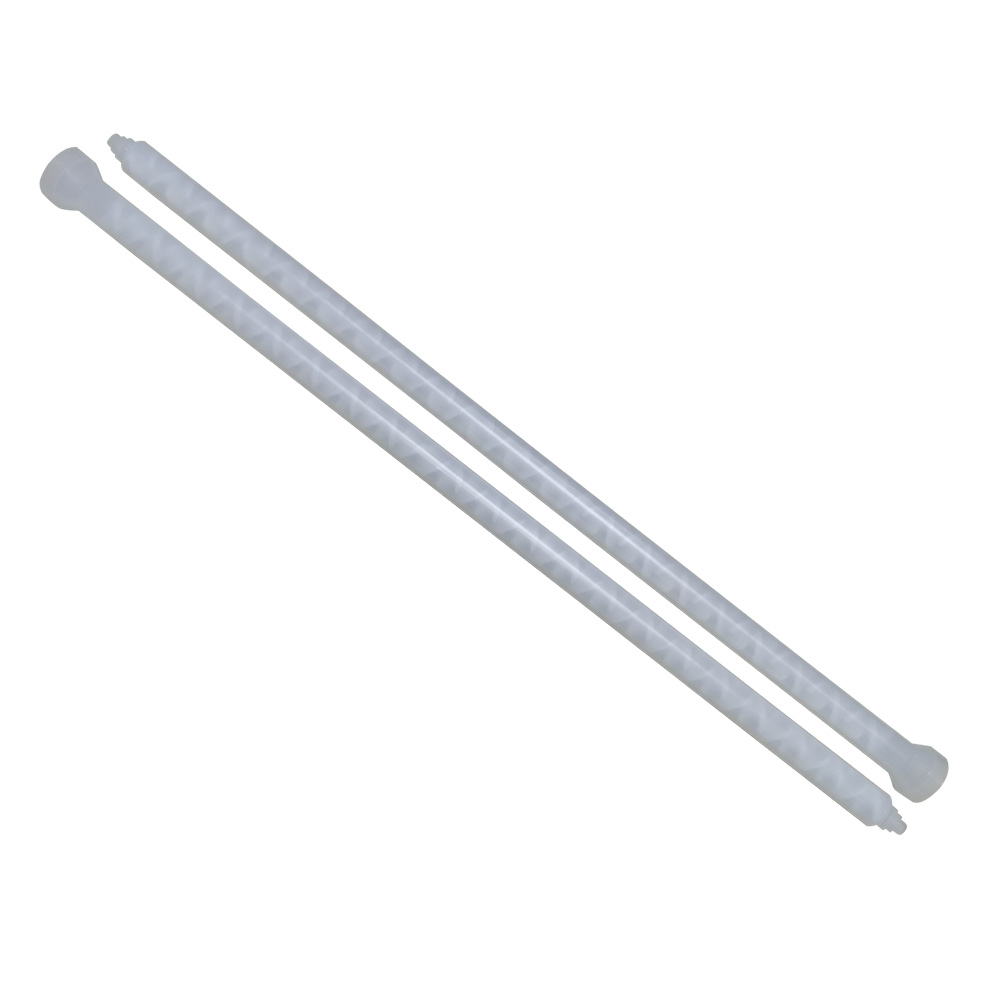

Resin nozzles, also known as static mixer nozzles, are specialized attachments used in conjunction with dispensing systems. These devices are responsible for combining and mixing two or more components, such as epoxy resins or adhesives, during the dispensing process. Resin nozzles typically consist of multiple chambers or elements that promote thorough mixing, ensuring a homogeneous blend of the resin materials.

Applications of Resin Nozzles:

Resin nozzles find application in a wide range of industries and projects that involve adhesive bonding, coating, sealing, or composite manufacturing. Some common areas where resin nozzles are utilized include:

-

Construction:

Resin nozzles are instrumental in concrete repair, crack injection, and anchoring applications. They ensure proper blending of the resin components, maximizing the strength and durability of the repaired structures.

-

Automotive and Aerospace:

Resin nozzles play a vital role in composite manufacturing processes for lightweight components. They enable precise dispensing of resin materials, ensuring consistent and reliable bonding in the production of composite parts.

-

Electronics:

In the electronics industry, resin nozzles are used in encapsulation processes for circuit board protection. These nozzles ensure accurate and uniform dispensing of potting compounds, enhancing the reliability and longevity of electronic devices.

-

Marine and Wind Energy:

Resin nozzles are essential in fiberglass lamination and repair applications for boats, wind turbine blades, and other marine structures. They facilitate efficient resin infusion, resulting in stronger and more durable composite materials.

Benefits of Resin Nozzles:

-

Accurate Mixing:

Resin nozzles provide precise and controlled mixing of resin components, ensuring consistent and homogeneous blends. This accuracy enhances the quality and performance of the final product or application.

-

Time and Cost Efficiency:

The efficient mixing process enabled by resin nozzles saves time and reduces material waste. By eliminating the need for manual mixing, these nozzles streamline production processes and enhance project efficiency.

-

Increased Strength and Performance:

Proper resin mixing achieved by resin nozzles enhances the adhesive properties, strength, and structural integrity of the end product. This results in improved performance and reliability, especially in critical applications.

-

Easy Integration:

Resin nozzles are designed to seamlessly integrate with dispensing systems, making them user-friendly and adaptable to various project requirements. They are available in different sizes and configurations, allowing for compatibility with different equipment and resin formulations.

-

Reduced Cleanup and Maintenance:

Resin nozzles minimize the need for excessive cleanup and maintenance. Their disposable or replaceable nature simplifies post-application cleanup, reducing downtime and optimizing productivity.

Conclusion:

Resin nozzles are indispensable tools in industries where precise and efficient resin mixing is crucial for achieving superior results. Their accurate blending capabilities, time and cost efficiency, increased strength and performance, easy integration, and reduced cleanup and maintenance make them invaluable assets to various projects. Whether you’re involved in construction, manufacturing, or other resin-based applications, utilizing resin nozzles can significantly enhance your project efficiency, productivity, and overall outcomes.