The Impact of Heat on Epoxy Mixing Nozzles

Heat can significantly impact the functionality and performance of epoxy mixing nozzles, leading to changes in viscosity, curing time, and potentially affecting nozzle integrity.

Spiral Mixing Nozzles vs Square Mixing Nozzles

Spiral mixing nozzles excel in enhanced mixing and reduced pressure drop, while square mixing nozzles offer turbulence generation and higher shear rates.

Static Mixing Nozzles vs. Dynamic Mixing Nozzles for Adhesive Applications

For applications requiring consistent blending across a range of viscosities, static mixing nozzles are an ideal choice.

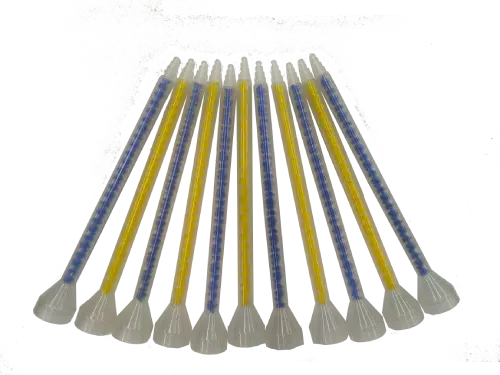

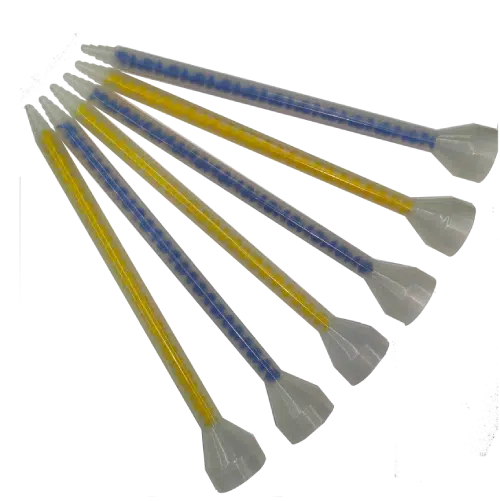

Which adhesive requires plastic mixing nozzles

Plastic mixing nozzles for a variety of adhesive formulations, including two-component epoxy, polyurethane, silicone, acrylic, structural, and UV-curable adhesives.

What happens if you don’t mix epoxy enough

One of the primary consequences of insufficient mixing is incomplete curing. Insufficient mixing can also result in poor adhesion between surfaces.

How to mix small amounts of epoxy resin

In conclusion, if you want the small amounts of epoxy resin mixed perfectlyfor, then Method 2: Dual-Syringe Dispensing and Method 3: Micro Batch Mixing are the best choices.

Plastic Static Mixer vs. Metal Static Mixer

Plastic mixers offer excellent chemical resistance and cost-effectiveness, making them suitable for moderate operating conditions.

What happens if you over mix epoxy

Over-mixing epoxy can lead to various problems, including reduced working time, increased heat generation, air bubble formation, and weakened bond strength.

Can Mixing Nozzles be Reused

When it comes to mixing nozzles, they can generally be categorized as either disposable or reusable. Disposable nozzles are intended for single-use applications and are typically made of plastic.

Plastic mixing nozzles for polyurethane adhesives

Plastic mixing nozzles offer a superior mixing solution for polyurethane adhesives, ensuring consistent and reliable bonding performance.