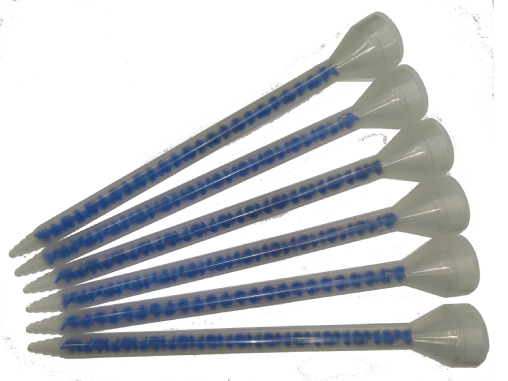

Plastic mixing nozzles are widely utilized in adhesive applications, offering excellent compatibility and performance for specific adhesive formulations. These specialized nozzles ensure proper mixing and dispensing of adhesives, maximizing bonding strength and promoting optimal curing. In this article, we will explore various adhesive types that benefit from plastic mixing nozzles, providing a comprehensive guide to help you choose the right nozzle for your adhesive applications.

Two-Component Epoxy Adhesives:

Two-component epoxy adhesives are commonly used in industries such as construction, automotive, aerospace, and electronics. These adhesives consist of a resin and a hardener that must be thoroughly mixed before application. Plastic mixing nozzles are well-suited for two-component epoxy adhesives due to their chemical resistance and compatibility. The nozzles ensure accurate and consistent mixing, resulting in strong, durable bonds.

Polyurethane Adhesives:

Polyurethane adhesives are versatile and widely used in applications where flexibility, impact resistance, and strong bonding are required. Plastic mixing nozzles are an ideal choice for polyurethane adhesives as they offer excellent resistance to the chemicals present in these adhesives. The nozzles enable precise blending of the polyurethane components, ensuring efficient bonding and reliable performance.

Silicone Adhesives and Sealants:

Silicone adhesives and sealants are known for their excellent heat resistance, flexibility, and electrical insulation properties. Plastic mixing nozzles are commonly used with silicone adhesives due to their compatibility with these formulations. The nozzles facilitate accurate mixing, allowing for precise application of the silicone adhesive or sealant, resulting in effective bonding and sealing in various industries, including electronics and automotive.

Acrylic Adhesives:

Acrylic adhesives are widely employed in industries such as signage, construction, and automotive assembly. These adhesives offer fast curing times, excellent bond strength, and versatility across various substrates. Plastic mixing nozzles are suitable for acrylic adhesives due to their compatibility with the adhesive’s chemistry. The nozzles enable efficient mixing and dispensing of the adhesive, ensuring proper bonding and effective assembly.

Structural Adhesives:

Structural adhesives, such as cyanoacrylates (super glue) and methacrylate adhesives, are used for bonding a wide range of materials, including metals, plastics, and composites. Plastic mixing nozzles are commonly used with these adhesives due to their chemical compatibility and ability to withstand the fast curing properties of these adhesives. The nozzles enable accurate blending of the adhesive components, ensuring strong and reliable bonds in various applications.

UV-Curable Adhesives:

UV-curable adhesives are gaining popularity due to their rapid curing capabilities when exposed to ultraviolet light. These adhesives offer excellent adhesion and are used in industries such as electronics, optics, and medical devices. While plastic mixing nozzles may not be required for UV-curable adhesives during the mixing process, they are often used for dispensing the adhesive onto the substrate. Plastic nozzles can resist the UV exposure and ensure precise application of the adhesive.

Conclusion:

In conclusion, Plastic mixing nozzles offer excellent compatibility and performance for a variety of adhesive formulations, including two-component epoxy, polyurethane, silicone, acrylic, structural, and UV-curable adhesives. By leveraging the advantages of plastic mixing nozzles, you can enhance the quality, durability, and performance of your adhesive applications, setting the foundation for successful bonding across a wide range of industries.