Epoxy mixing nozzles play a pivotal role in industries requiring precise and efficient blending of epoxy resins. Their significance lies in ensuring accurate ratios and thorough mixing, directly impacting the quality and durability of end products across various applications.

Understanding Epoxy Mixing Nozzles

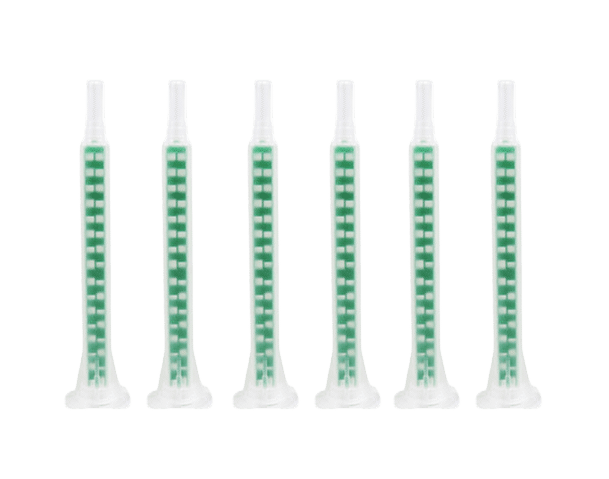

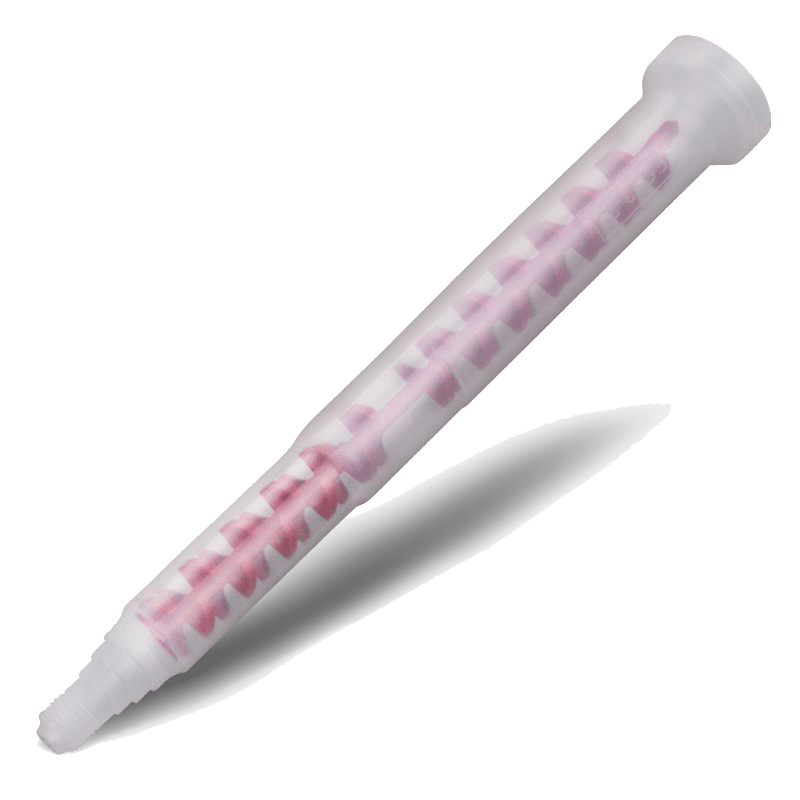

Epoxy mixing nozzles typically fall into two primary categories: static and dynamic mixing nozzles. Static mixing nozzles utilize internal elements to blend the resins, while dynamic mixing nozzles rely on external forces for mixing. Both types work harmoniously to ensure the uniform and consistent mixing of epoxy components during dispensing, a critical factor in achieving predictable and reliable outcomes in epoxy-related tasks.

Static Mixing Nozzles

Static mixing nozzles comprise a series of fixed elements within the nozzle, designed to divide, twist, and recombine the epoxy components as they flow through. This intricate internal structure facilitates blending without the need for any additional energy sources, relying solely on the resin’s flow for effective mixing.

Dynamic Mixing Nozzles

Dynamic mixing nozzles operate through external mechanisms, harnessing rotational or oscillatory movement to induce mixing. These nozzles typically employ additional elements like impellers or vanes, which agitate the epoxy components as they pass through, ensuring thorough blending before dispensing.

The Science Behind Epoxy Mixing Nozzles

The functionality of epoxy mixing nozzles is rooted in their intricate design elements, meticulously engineered to facilitate the proper blending of epoxy components. The internal structures of these nozzles serve a critical purpose, ensuring that the resin components are thoroughly and uniformly mixed during the dispensing process.

Design Elements

The internal structure of mixing nozzles is carefully crafted to create turbulence and shear forces within the resin flow. This design prevents the components from segregating, allowing for a homogenous blend. Various geometrical configurations and materials are employed in nozzle design to optimize mixing efficiency based on specific epoxy formulations and viscosities.

Mixing Process

Proper mixing is imperative for the chemical reaction of epoxy components to occur uniformly, ensuring the desired strength and properties of the cured resin. Inadequate mixing can result in uneven curing, weak spots, or compromised material properties, leading to suboptimal performance in the final product.

The careful engineering behind epoxy mixing nozzles guarantees a consistent and thorough blending process, contributing significantly to the overall quality and performance of epoxy-based applications. This understanding lays the foundation for selecting the right nozzle and employing best practices for efficient and effective resin mixing.

Applications Across Industries

The versatility of epoxy mixing nozzles extends across diverse industries, showcasing their pivotal role in various applications:

- Construction: In the construction sector, these nozzles are instrumental in bonding, filling, and repairing structures. They ensure precise dispensing and mixing, enhancing the structural integrity and longevity of constructions.

- Automotive: Epoxy mixing nozzles find extensive use in the automotive industry for adhesive applications during vehicle manufacturing. From bonding parts to sealing components, these nozzles ensure strong and durable bonds critical for vehicle safety and performance.

- Electronics: Within electronics, these nozzles aid in potting and encapsulating sensitive electronic components. The precise blending of resins safeguards delicate parts from environmental factors and enhances their reliability.

- Aerospace: Epoxy mixing nozzles play a crucial role in composite manufacturing and repairs within the aerospace industry. They enable the creation of strong and lightweight structures, contributing to the efficiency and safety of aerospace components.

Choosing the Right Epoxy Mixing Nozzle

Selecting the appropriate epoxy mixing nozzle involves considering several factors to ensure optimal performance:

- Viscosity and Output: Understanding the viscosity of the epoxy and the desired output rate is crucial. Different nozzles are designed to handle varying viscosities and deliver specific flow rates, impacting the mixing process.

- Application Method: Whether it’s manual dispensing or automated systems, the choice of nozzle should align with the application method. Some nozzles are designed for handheld use, while others integrate seamlessly into automated machinery.

- Comparison of Nozzle Designs: Evaluating the designs of various nozzles available in the market is essential. Factors such as mixing efficiency, compatibility with specific resins, and ease of use should be considered when making a selection.

Best Practices and Tips

To maximize the efficiency and longevity of epoxy mixing nozzles, it’s essential to follow best practices:

- Proper Usage: Adhering to the manufacturer’s instructions for nozzle usage and ensuring the correct installation and operation is crucial for optimal performance.

- Maintenance: Regular cleaning and maintenance of the nozzles prevent residue buildup, ensuring consistent and reliable mixing in the long run.

-

Temperature Considerations: Acknowledge the influence of temperature on epoxy performance during the mixing process.

- Viscosity Control: Understand that temperature variations affect epoxy viscosity. Higher temperatures decrease viscosity, allowing for easier flow through the nozzle, while lower temperatures increase viscosity, potentially impacting the flow rate and mixing efficiency.

- Curing Time Awareness: Temperature variations also impact curing time. Higher temperatures accelerate curing, demanding quicker application, while lower temperatures slow down curing, requiring careful monitoring.

- Material Compatibility: Ensure that the materials used in the nozzle construction can withstand varying temperatures without affecting epoxy quality or causing adverse reactions.

- Safety Measures: Adhering to safety protocols when handling epoxy resins and using the nozzles is imperative to prevent accidents and ensure a secure working environment.

Conclusion

Epoxy mixing nozzles are integral tools that significantly impact the quality and durability of epoxy-based applications across various industries. Understanding their functionality, selecting the right nozzle, and employing best practices are key to achieving precise and efficient resin mixing, ultimately contributing to superior end-product quality and performance.