Picture this: You’re scrolling through Instagram, mesmerized by a glossy, crystal-clear tabletop embedded with swirling pigments, or maybe you’re marveling at a sleek, corrosion-resistant car part. What’s the secret behind these creations? Epoxy resin—a material that’s as versatile as it is captivating. Whether you’re a DIY enthusiast dreaming up your next project or a professional in construction or aerospace, epoxy resin is likely already part of your world—or it’s about to be. So, what is epoxy resin, and why is everyone obsessed with it? Let’s dive in and uncover the magic of this game-changing polymer.

What Is Epoxy Resin, Exactly?

At its core, epoxy resin is a two-part synthetic polymer that transforms from a liquid or paste into a rock-solid, durable material through a chemical reaction. Think of it like a culinary recipe: you mix the resin (the main ingredient) with a hardener (the catalyst), and voilà—a high-strength, adhesive powerhouse is born. Typically mixed in ratios like 2:1 or 4:1, this combo cures into a thermoset polymer, meaning it’s heat-resistant, tough, and doesn’t melt once set.

But here’s where it gets fun: epoxy isn’t just one thing. It’s a family of materials, with endless formulations tailored to specific needs. From glossy art pieces to bulletproof aerospace components, epoxy resin’s adaptability is its superpower. It’s like the Swiss Army knife of materials—there’s a version for almost every job.

What is the advantage of Epoxy Resin?

Epoxy resin isn’t just strong; it’s epic. Here’s why it’s a favorite across industries:

- Unbreakable Bond: Epoxy sticks to almost anything—wood, metal, glass, concrete, even most plastics. It’s like the glue you wished you had in middle school art class, but way better.

- Chemical Warrior: Spill some harsh chemicals? No problem. Epoxy laughs in the face of alkaline environments and corrosive substances.

- Heat Tolerant: Some formulations handle temperatures up to 350°F (177°C), though it might start to sweat a bit at the higher end.

- Low Shrinkage: Unlike other materials that warp or shrink during curing, epoxy stays put, delivering precision and stability.

- Electrical Shield: It’s a fantastic insulator, protecting electronics from moisture, dust, and short circuits.

- Fatigue Fighter: Epoxy can handle constant stress and cyclic loading, making it perfect for dynamic applications like wind turbine blades.

Types of Epoxy Resin: A Flavor for Every Need

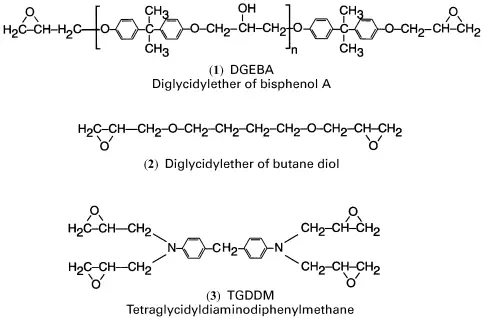

Not all epoxy resins are created equal. They come in two main categories— glycidyl and non-glycidyl —each with subtypes designed for specific vibes:

- Glycidyl-Ether (e.g., DGEBA): The crowd favorite, made from bisphenol-A and epichlorohydrin. It’s low-molecular-weight and perfect for everything from coatings to adhesives.

- Glycidyl-Amine: High-functionality, low-viscosity, and fast-curing—ideal for aerospace composites that need to be tough yet lightweight.

- Cycloaliphatic Epoxy: UV-stable and weather-resistant, these are your go-to for outdoor applications.

- Novolac Epoxy: Built for harsh environments, these offer top-tier chemical resistance.

- Halogenated Epoxy: Flame-resistant and used in electrical systems where safety is non-negotiable.

Each type is like a custom playlist—pick the one that matches your project’s mood.

Where Epoxy Resin Shines: Real-World Applications

Epoxy resin is everywhere, from your garage floor to the skies above. Here’s a peek at where it’s making waves:

1. Construction: Building the Future

Epoxy is the unsung hero of construction. It’s used in:

- Structural Adhesives: Bonding laminated wood, concrete, and metal for walls, roofs, and decks.

- Flooring: Creating glossy, chemical-resistant surfaces for industrial spaces or chic terrazzo floors in trendy cafes.

- Concrete Repair: Filling cracks to restore structural integrity.

- Waterproofing: Coating pipes and tanks to keep leaks at bay.

2. Aerospace: Reaching for the Stars

In aerospace, epoxy teams up with carbon or glass fibers to create lightweight, durable components. It’s the glue that holds aircraft and satellites together, resisting extreme temperatures and environmental stress.

3. Electronics: Powering the Digital Age

Epoxy protects motors, transformers, and circuit boards from moisture and dust. It’s like a superhero cape for your electronics, ensuring they stay safe and functional.

4. Automotive: Driving Innovation

From anti-corrosive primers to lightweight composites, epoxy helps cars stay rust-free and fuel-efficient. It’s been a staple in auto manufacturing for over 30 years.

5. Art & DIY: Unleashing Creativity

Epoxy resin is a darling of the DIY world. Mixed with pigments, it creates stunning jewelry, vibrant tabletops, or encapsulated natural treasures like flowers. I once saw an artist embed a tiny seashell in a resin pendant—it was like capturing a piece of the ocean.

6. Renewable Energy: Saving the Planet

Epoxy strengthens wind turbine blades and enhances solar and battery systems, making renewable energy more efficient and scalable.

7. Food Packaging: Keeping It Fresh

Ever wonder why canned food stays safe? Epoxy coatings create a protective barrier, preventing metal corrosion and preserving taste and nutrition.

The Curing Process: From Liquid to Legend

The magic of epoxy happens during curing, when the resin and hardener react to form a cross-linked, rock-hard structure. Here’s how it works:

- Mixing: Combine resin and hardener in precise ratios (think 2:1 or 4:1). Accuracy is key—too much or too little hardener, and your project could flop.

- Pot Life: This is your window to work with the mixture before it starts to set. Think of it as the countdown before the epoxy says, “I’m done being liquid.”

- Gel Time: The mix turns viscous and gel-like, losing its flow. It’s the awkward teenage phase of curing.

- Full Cure: After up to 72 hours, your epoxy is fully hardened and ready to take on the world.

To make this process easier, especially when working with epoxy resin in 1:1 ratios, Btektech provides professional cartridge solutions for precise and efficient mixing:

- 50ml 1:1 Dual Cartridge – Perfect for small projects, craft applications, and precision work.

- 400ml 1:1 Dual Cartridge – Ideal for larger-scale applications such as flooring, construction bonding, or composite work.

Both options are designed to work seamlessly with epoxy resin, ensuring accuracy and saving you time during preparation

Safety First: Handling Epoxy Like a Pro

Uncured epoxy can be a bit of a diva, so handle it with care. Here’s how to stay safe:

- Gear Up: Wear nitrile gloves, safety goggles, and a plastic apron. If ventilation is lacking, a respirator is your best friend.

- Ventilation: Work in a well-ventilated space or use a fume hood to avoid inhaling fumes.

- Skin Contact: If epoxy gets on your skin, wipe it off with baby wipes, then wash with soap and water. Avoid solvents—they can make things worse.

- Eye Contact: Flush with water for 15 minutes and seek medical help ASAP.

Once cured, epoxy is inert and safe, but until then, treat it like a spicy chili—you don’t want it in your eyes or on your skin.

Why Epoxy Resin Is Trending in 2025

Epoxy resin is having a moment, and it’s not just because of its strength. The DIY scene is buzzing with resin art tutorials on TikTok, where creators pour vibrant colors into molds to craft everything from coasters to statement necklaces. In construction, eco-conscious builders are using epoxy to extend the lifespan of structures, reducing waste. Even in renewable energy, epoxy’s role in wind and solar tech is making it a green hero.

Meet Btektech: Your Partner in Precision Epoxy Dispensing

As a leading manufacturer and supplier of precision dispensing equipment, our innovative technology ensures consistent, accurate application of epoxy, helping businesses achieve efficiency and cost savings of up to 40% compared to other brands. Whether you’re sealing circuit boards or crafting composites, BTEK’s equipment makes epoxy application seamless and reliable.

If you have any questions or needs about Epoxy Resin and our products, our online technicians are always available to answer your questions.