Epoxy nozzles play a crucial role in the application of epoxy resin, ensuring precise mixing and dispensing for various projects. Understanding the different types of epoxy mixing nozzles and how they work can help users make informed decisions about their use and maintenance.

Types of Epoxy Nozzles

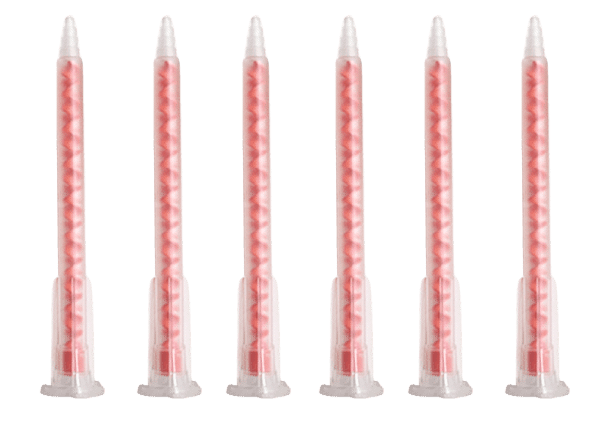

Static Mixing Nozzles: These are commonly used with dual-cartridge epoxy systems. They contain elements that ensure thorough mixing of the resin and hardener as they pass through the nozzle, providing a homogenous mixture for application.

Dynamic Mixing Nozzles: Similar to static mixing nozzles, dynamic mix nozzles also mix the epoxy components as they pass through. However, they use a different mechanism, often involving rotating elements, to achieve the mixing.

Disposable vs. Reusable Nozzles: Epoxy nozzles can be disposable, meaning they are discarded after a single use, or reusable, allowing them to be cleaned and reused multiple times. The choice between disposable and reusable nozzles depends on the application requirements and budget considerations.

How Epoxy Nozzles Work

Epoxy nozzles are designed to ensure the proper mixing and dispensing of epoxy resin and hardener. Here’s a basic overview of how they work:

Mixing Chamber: Epoxy nozzles contain a mixing chamber where the resin and hardener are combined. In static mix nozzles, this chamber contains mixing elements that ensure thorough blending of the two components.

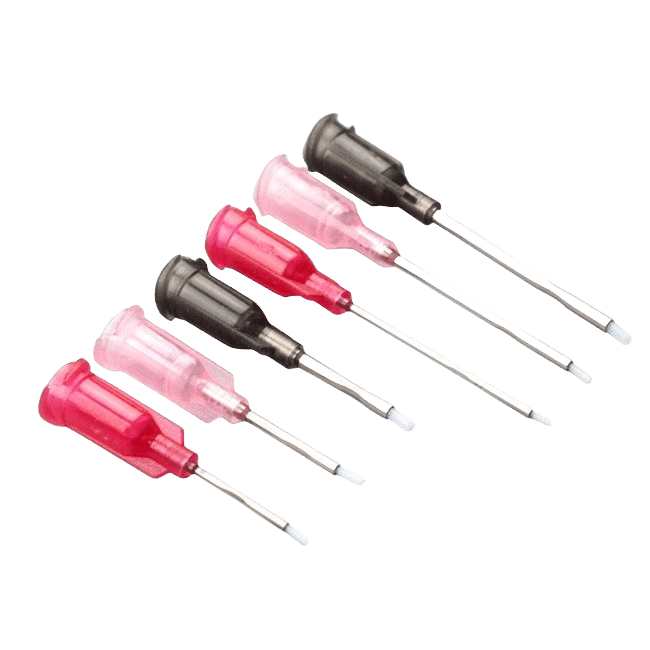

Dispensing Tip: The dispensing tip of the nozzle controls the flow of the mixed epoxy. It can vary in size and shape depending on the application requirements.

Trigger Mechanism: For manual dispensing guns, a trigger mechanism controls the flow of the epoxy through the nozzle. This allows users to precisely control the application.

Compatibility: It’s important to use a compatible nozzle with your epoxy system to ensure proper mixing and dispensing. Using an incorrect or incompatible nozzle can result in improper mixing, affecting the curing and performance of the epoxy.

Materials Used in Epoxy Nozzles

Epoxy nozzles are typically made from plastic or metal, with plastic being more common due to its cost-effectiveness and ease of manufacturing. Plastic nozzles are suitable for most epoxy applications but may be prone to cracking or damage if mishandled. Metal nozzles, on the other hand, are more durable but may be more expensive.

Causes of Cracked Epoxy Nozzles

Epoxy nozzles are essential for the proper dispensing and application of epoxy resin, but they can become cracked or damaged for various reasons. Understanding the causes of cracked epoxy nozzles can help users prevent damage and ensure the longevity of their equipment.

Physical Damage

One of the most common causes of cracked epoxy nozzles is physical damage. Dropping the dispensing gun or accidentally hitting the nozzle against a hard surface can cause cracks to form. Mishandling during storage or transportation can also lead to damage.

Chemical Exposure

Some chemicals in epoxy resin formulations can be corrosive and may weaken the material of the nozzle over time, leading to cracks. It’s important to use epoxy resin formulations that are compatible with the materials used in the nozzle to prevent chemical damage.

Environmental Factors

Environmental factors such as temperature changes and humidity can also contribute to the cracking of epoxy nozzles. Exposure to extreme temperatures can cause the material of the nozzle to expand and contract, leading to stress and eventual cracking.

Improper Use

Using excessive force when attaching or removing the nozzle from the dispensing gun can cause damage. It’s important to follow the manufacturer’s instructions for proper use and maintenance of the equipment to prevent unnecessary wear and tear.

Age and Wear

Like any tool, epoxy nozzles can deteriorate over time with regular use. Nozzles that are old or worn may be more prone to cracking. It’s important to inspect your epoxy nozzles regularly and replace them when signs of wear are detected.

Effects of a Cracked Epoxy Nozzle

A cracked epoxy nozzle can have several significant effects on the application process and the quality of the final product. Understanding these effects is crucial for users to assess the impact of a cracked nozzle and take appropriate action to rectify the situation.

Risk of Resin Leakage

One of the primary effects of a cracked epoxy mixing nozzle is the risk of resin leakage. Even small cracks can allow epoxy resin to escape, leading to messy and wasteful application. Resin leakage can also result in uneven or incomplete coverage, affecting the quality of the bond or finish.

Impact on Application Precision

A cracked epoxy nozzle can affect the precision of the application. The crack may alter the flow of the resin, leading to inconsistent dispensing. This can make it challenging to achieve the desired thickness or coverage, especially in detailed or intricate applications.

Quality of the Bond or Finish

Cracks in the epoxy nozzle can also affect the quality of the bond or finish. Uneven application due to resin leakage or altered flow can result in weak bonds or an uneven finish. This can compromise the structural integrity of the project or detract from its aesthetic appeal.

Increased Risk of Clogs

Leaked resin from a cracked nozzle can harden and clog the nozzle, making it unusable. This can result in downtime as the nozzle needs to be cleaned or replaced, affecting productivity and efficiency.

Safety Concerns

Using a cracked epoxy nozzle can also pose safety risks. The risk of resin leakage can lead to accidental spills or exposure to hazardous chemicals. Proper ventilation and personal protective equipment (PPE) should be used when working with epoxy resin, especially in cases where a cracked nozzle is involved.

Assessing the Damage

Assessing the extent of damage to a cracked epoxy nozzle is crucial for determining whether it can still be used or if it needs to be replaced. Several methods can be used to assess the damage and determine the best course of action.

Visual Inspection

A visual inspection is the first step in assessing the damage to a cracked epoxy nozzle. Look for visible cracks, chips, or other signs of damage on the surface of the nozzle. Pay attention to the size and location of the crack, as well as any signs of resin leakage.

Functional Testing

Performing a functional test can help determine if a cracked epoxy nozzle is still usable. Attach the nozzle to the dispensing gun and dispense a small amount of resin. Observe the flow of the resin and check for any signs of leakage or irregular flow. If the nozzle functions properly without any issues, it may still be usable.

Leak Testing

A leak test can help determine the severity of a crack and whether it is causing resin leakage. Seal off one end of the nozzle and fill it with water. Apply pressure to the nozzle and check for any signs of water leakage. If water leaks through the crack, it is likely that resin will also leak during use.

Professional Inspection

If you are unsure about the extent of damage to a cracked epoxy nozzle, it may be advisable to seek professional inspection. A professional can provide a more detailed assessment of the damage and recommend the best course of action, whether it’s repairing the nozzle or replacing it.

Safety Considerations

Using a cracked epoxy nozzle can pose several safety risks. It’s essential to be aware of these risks and take appropriate precautions to minimize them. Here are some key safety considerations when dealing with cracked epoxy nozzles:

Risk of Resin Leakage

One of the primary safety concerns associated with a cracked epoxy nozzle is the risk of resin leakage. Epoxy resin can be a skin and eye irritant and may cause allergic reactions in some individuals. Resin leakage can also result in contamination of the work area, leading to slips and falls.

Proper Ventilation

When working with epoxy resin, proper ventilation is essential to minimize exposure to fumes. A cracked nozzle can increase the risk of fumes escaping into the surrounding environment. Ensure that the work area is well-ventilated, and consider using a respirator or mask to protect against inhaling fumes.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment (PPE) is crucial when working with epoxy resin, especially when using a cracked nozzle. Wear gloves to protect your hands from contact with the resin and safety goggles to protect your eyes from splashes. Long sleeves and pants can also help protect your skin from exposure.

Cleaning Up Spills

If resin leaks from a cracked nozzle and spills onto the work surface, it’s essential to clean it up promptly and properly. Use a solvent recommended by the resin manufacturer to clean up spills, and dispose of any contaminated materials according to local regulations.

Replacement

In many cases, the safest course of action when dealing with a cracked epoxy nozzle is to replace it. Using a damaged nozzle can increase the risk of accidents and exposure to hazardous materials. Always follow the manufacturer’s recommendations for replacing damaged nozzles.

Can a Cracked Epoxy Nozzle Still Be Used?

The usability of a cracked epoxy nozzle depends on several factors, including the size and location of the crack, as well as the extent of the damage. While some minor cracks may not significantly affect the performance of the nozzle, larger or more severe cracks can compromise its integrity and usability. Here are some considerations when determining if a cracked epoxy nozzle can still be used:

Size and Location of the Crack

Small, superficial cracks that do not extend into the inner chamber of the nozzle may not affect its performance significantly. However, cracks that are large or extend into the inner chamber can compromise the integrity of the nozzle and lead to issues such as resin leakage and uneven dispensing.

Extent of the Damage

The extent of the damage to the nozzle is also a crucial factor in determining its usability. If the crack is minor and does not affect the functionality of the nozzle, it may still be usable. However, if the crack is severe and compromises the structural integrity of the nozzle, it is advisable to replace it.

Risk of Resin Leakage

One of the primary concerns with a cracked epoxy nozzle is the risk of resin leakage. Even small cracks can allow resin to seep through, leading to messy and wasteful application. If the crack is likely to cause resin leakage, it is best to replace the nozzle to avoid potential issues.

Safety Considerations

Using a cracked epoxy nozzle can also pose safety risks, especially if the crack compromises the seal between the nozzle and the dispensing gun. This can increase the risk of accidental spills or exposure to hazardous materials. It is important to prioritize safety and replace the nozzle if there is any doubt about its usability.

Preventing Cracked Epoxy Nozzles

Preventing cracked epoxy nozzles is essential to ensure the efficient and safe application of epoxy resin. By following proper handling, storage, and maintenance practices, users can minimize the risk of damage to their epoxy nozzles. Here are some tips for preventing cracked epoxy nozzles:

Handle with Care

Avoid dropping or mishandling the dispensing gun, as this can cause damage to the nozzle.

When attaching or removing the nozzle, do so gently and without applying excessive force.

Proper Storage

Store the dispensing gun and epoxy cartridges in a cool, dry place to prevent damage from environmental factors.

Use nozzle caps or guards to protect the nozzle when not in use.

Regular Inspection

Inspect the nozzle before each use to check for any signs of damage or wear.

Look for cracks, chips, or other damage that may compromise the integrity of the nozzle.

Use Correctly

Follow the manufacturer’s instructions for using the dispensing gun and epoxy cartridges.

Use the correct nozzle size and type for your epoxy system to ensure proper mixing and dispensing.

Maintenance

Clean the nozzle thoroughly after each use to prevent resin buildup that can lead to clogs and damage.

Replace the nozzle if it shows signs of wear or damage, even if it is still usable.

Replacing a Cracked Epoxy Nozzle

Replacing a cracked epoxy nozzle is essential to ensure the continued performance and safety of the epoxy application process. Here’s a step-by-step guide to replacing a cracked epoxy nozzle:

1. Remove the Old Nozzle

Unscrew the old nozzle from the dispensing gun. Use caution to avoid spilling any resin that may be remaining in the nozzle.

2. Clean the Dispensing Gun

Before attaching the new nozzle, clean the dispensing gun to remove any resin residue that may have accumulated.

3. Attach the New Nozzle

Screw the new nozzle onto the dispensing gun until it is securely in place. Ensure that it is properly aligned to ensure smooth and even dispensing.

4. Test the Dispensing Gun

Before using the dispensing gun with the new nozzle, test it to ensure that resin flows smoothly and evenly.

5. Dispose of the Old Nozzle

Dispose of the old nozzle properly, following any local regulations for the disposal of hazardous materials.

6. Check for Proper Functionality

After replacing the nozzle, check the dispensing gun for proper functionality. Ensure that resin flows smoothly and evenly through the new nozzle.

7. Monitor for Leakage

Monitor the new nozzle for any signs of leakage during use. If leakage occurs, check the nozzle for cracks or other damage and replace if necessary.

8. Regular Maintenance

After replacing the nozzle, continue to perform regular maintenance on the dispensing gun and nozzle to ensure optimal performance and longevity.

Conclusion

In conclusion, a cracked epoxy nozzle can have significant implications for the efficiency, quality, and safety of epoxy application. Understanding the causes and effects of cracked nozzles is crucial for users to assess the damage and take appropriate action. While minor cracks may not immediately impact the usability of the nozzle, it is generally advisable to replace damaged nozzles promptly to avoid potential issues with resin leakage, uneven dispensing, and safety risks.

By following proper handling, storage, and maintenance practices, users can minimize the risk of damage to their epoxy nozzles and ensure smooth and efficient epoxy application. Regular inspection and replacement of damaged nozzles, as well as proper disposal of old nozzles, are essential steps in maintaining the integrity of the epoxy application process.

Overall, the key to preventing cracked epoxy nozzles is diligence and attention to detail. By following the guidelines outlined in this article, users can ensure the continued performance and safety of their epoxy application process, leading to successful and high-quality epoxy projects.