3D printing, also known as additive manufacturing, has witnessed remarkable advancements in recent years. One of the key technologies contributing to this progress is the integration of static mixing nozzles. These nozzles are transforming the 3D printing landscape, offering enhanced precision, material versatility, and overall print quality. In this blog post, we will delve into the fascinating world of static mixing nozzles in 3D printing and explore their impact on this rapidly evolving industry.

Understanding Static Mixing Nozzles

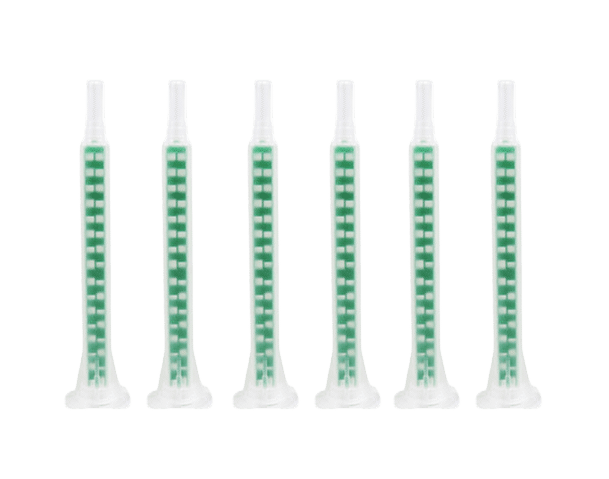

Static mixing nozzles are devices designed to thoroughly blend two or more materials before extrusion. In 3D printing, this typically involves the mixing of different colors or types of filaments, such as PLA and ABS, to create intricate, multi-material or multi-color prints. Unlike traditional mixing methods that rely on mechanical agitation, static mixing nozzles use a unique geometry to achieve uniform material blending. This design minimizes mechanical wear and ensures consistent mixing.

Advantages of Static Mixing Nozzles in 3D Printing

-

Color Blending:

Static mixing nozzles enable seamless transitions between colors, allowing for intricate and visually stunning 3D prints. This capability is particularly valuable in the production of prototypes, models, and artistic creations.

-

Material Versatility:

Beyond color, static mixing nozzles open the door to mixing different types of filaments. This means you can combine materials with varying properties, such as flexibility, rigidity, or conductivity, to achieve desired characteristics in your prints.

-

Reduced Waste:

Static mixing minimizes material waste by ensuring that each drop of filament is effectively utilized. This can be especially cost-effective for large-scale 3D printing projects.

-

Enhanced Print Quality:

The consistent mixing provided by static mixing nozzles results in prints with smoother transitions and fewer defects, such as color streaks or uneven material distribution.

Applications in 3D Printing

Static mixing nozzles find applications in a wide range of industries and creative endeavors:

-

Art and Design:

Artists and designers can create visually striking 3D prints with intricate color patterns and gradients.

-

Prototyping:

Engineers and product designers use static mixing to produce functional prototypes with various material properties, simulating the behavior of finished products.

-

Custom Manufacturing:

Manufacturers can tailor material properties to meet specific requirements, such as flexible joints in robotics or conductive traces in electronics.

Choosing the Right Static Mixing Nozzle

Selecting the appropriate static mixing nozzle for your 3D printer is crucial. Consider factors such as nozzle size, compatibility with your printer, and the materials you intend to use. Consult with nozzle manufacturers or 3D printing experts to make an informed choice.

Conclusion

Static mixing nozzles have ushered in a new era of creativity and functionality in 3D printing. As the technology continues to evolve, we can expect even more exciting developments in this field. Whether you’re a professional engineer, a hobbyist, or an artist, static mixing nozzles offer a valuable tool for pushing the boundaries of what’s possible in the world of 3D printing. Embrace this innovation and unlock the full potential of your 3D printer.