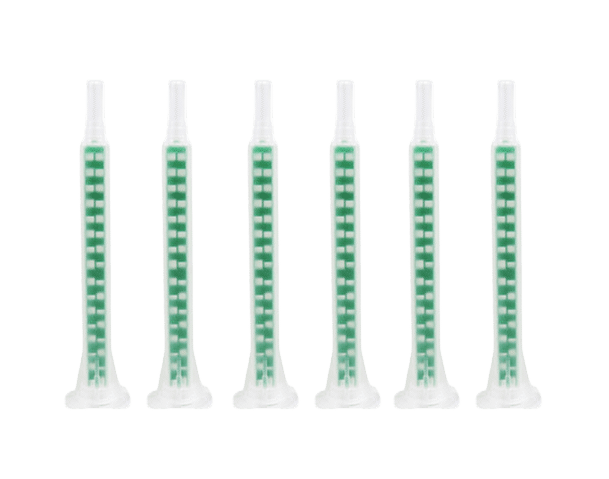

Static mixing nozzles are commonly used in various industries, including the packing industry, depending on the specific processes and requirements. The decision to use static mixing nozzles in the packing industry would depend on the nature of the materials being processed and the desired outcome. Here are some situations in which static mixing nozzles might be used in the packing industry:

Dispensing Adhesives:

In the production of packaging materials or products, adhesives are often used to bond different components together. Static mixing nozzles can be used to mix and dispense two-part adhesives, ensuring a thorough and consistent mix before application. This helps in achieving strong bonds and improving product quality.

Colorant or Additive Mixing:

When adding colorants, additives, or other materials to packaging materials, achieving uniform distribution is crucial for product consistency. Static mixing nozzles can be used to mix these additives with the base materials effectively.

Sealant Application:

In sealing processes, such as applying sealant to packaging seams or joints, static mixing nozzles can ensure that the sealant is thoroughly mixed and applied uniformly, creating reliable seals.

Coating and Laminating:

Static mixing nozzles can be used in the application of coatings or laminates to packaging materials. This ensures an even and consistent distribution of the coating, which can enhance the appearance and protective properties of the packaging.

Foaming and Filling:

In the packaging of products that involve foaming or filling processes, static mixing nozzles can be used to mix the components (such as gas and liquid) to create foams or fill containers uniformly.

Chemical and Ingredient Blending:

In some cases, the packing industry may deal with the blending of chemicals or ingredients for various purposes, and static mixing nozzles can help achieve a consistent blend.

Static mixing nozzles are particularly useful when precise mixing and uniform distribution are critical to the quality and performance of the end product. They are also advantageous because they are simple, cost-effective, and do not rely on moving parts or external energy sources for mixing.

The specific need for static mixing nozzles in the packing industry will depend on the processes and materials involved. Before implementing static mixing nozzles, it’s essential to evaluate the requirements of the application and determine whether they will bring benefits in terms of product quality and process efficiency.