General Industrial Manufacturing

Perfect for reaching deep grooves or curved channels where rigid tips cannot fit. Provides consistent material placement while minimizing waste, suitable for both manual and automated dispensing operations.

Bendable, Cuttable & Scratch-Free Solutions for Hard-to-Reach Dispensing

Btektech Flexible Dispensing Tips are engineered from high-quality polypropylene (PP) for scratch-free dispensing in sensitive environments. Available in both glue-bonded PP and one-piece molded PP constructions to match different cost-performance and chemical resistance requirements.

Highly bendable polypropylene (PP) needle allow controlled fluid application in confined or hidden spaces. Each needle can be easily trimmed to the required length for optimized flow based on viscosity and process needs.

The soft PP needle prevents abrasion or surface damage to delicate components such as coatings, chips, lenses, and housings.

Select from two PP needle types: the cost-effective glue-bonded version for general use, or the one-piece integrated (P-Series) for superior chemical resistance for harsh fluids. Both types are scratch-free and share PP’s temperature limits.

Ideal for dispensing flux, UV adhesives, and conformal coatings in compact PCB layouts. The flexible needle allows safe access near fragile solder joints and micro-components, minimizing rework or accidental damage.

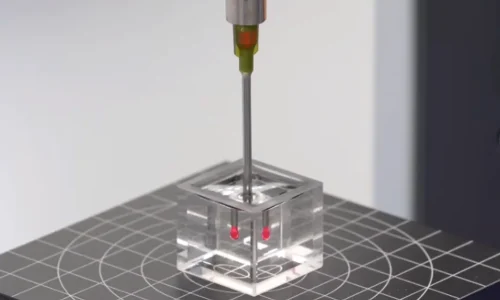

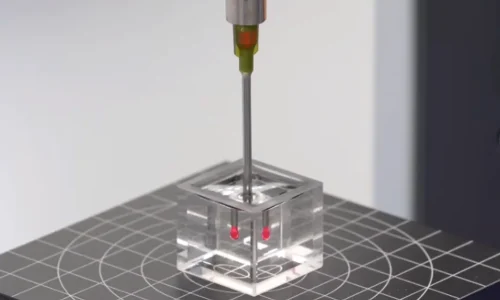

Ensures accurate micro-volume dispensing of lubricants and bonding agents for diagnostic devices and plastic lab components. The flexible body allows routing around curved surfaces while maintaining precise control and preventing contamination.

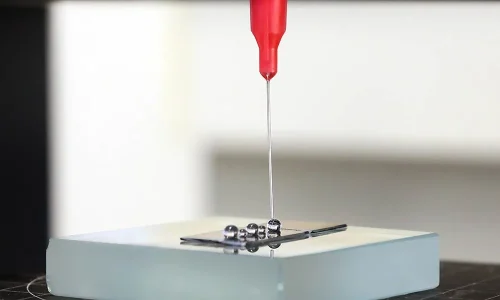

Perfect for reaching deep grooves or curved channels where rigid tips cannot fit. Provides consistent material placement while minimizing waste, suitable for both manual and automated dispensing operations.

Explore the complete range of Btektech Flexible Dispensing Tips in the table below. Each model’s part number links to its detailed specifications and pricing sheet. For a comprehensive overview of all our dispensing consumables, please contact us or download the product catalog.

| Gauge | Color | ID(mm) | OD(mm) | 6.35mm (1/4″) | 12.7mm (1/2″) | 25.4mm (1″) | 38.1mm (3/2″) | |

| 14 | Olive | 1.3 | 1.78 | FT 14025 | FT 14050 | FT 14100 | FT 14150 | |

| 15 | Amber | 1.1 | 1.78 | FT 15025 | FT 15050 | FT 15100 | FT 15150 | |

| 16 | Grey | 1 | 1.65 | FT 16025 | FT 16050 | FT 16100 | FT 16150 | |

| 18 | Green | 0.84 | 1.26 | FT 18025 | FT 18050 | FT 18100 | FT 18150 | |

| 20 | Pink | 0.6 | 0.9 | FT 20025 | FT 20050 | FT 20100 | FT 20150 | |

| 22 | Blue | 0.41 | 0.7 | FT 22025 | FT 22050 | FT 22100 | FT 22150 | |

| 25 | Red | 0.3 | 0.78 | FT 25025 | FT 25050 | FT 25100 | FT 25150 | |

| Gauge | Color | ID(mm) | OD(mm) | 12.7mm(1/2″) | 25.4mm(1″) | |

| 14 | Clear | 1.55 | 1.84 | CRT 14050 | CRT 14100 | |

| 15 | Clear | 1.2 | 1.64 | CRT 15050 | CRT 15100 | |

| 18 | Red | 0.84 | 1.28 | CRT 18050 | CRT 18100 | |

| 20 | Yellow | 0.6 | 1.05 | CRT 20050 | CRT 20100 | |

| 22 | Clear | 0.4 | 0.9 | CRT 22050 | CRT 22100 | |

| 25 | Clear | 0.3 | 0.8 | CRT 25050 | CRT 25100 | |

Glue-bonded PP tips:

| Gauge | Color | ID(mm) | OD(mm) | 6.35mm (1/4″) | 12.7mm (1/2″) | 25.4mm (1″) | 38.1mm (3/2″) | |

| 14 | Olive | 1.3 | 1.78 | FT 14025 | FT 14050 | FT 14100 | FT 14150 | |

| 15 | Amber | 1.1 | 1.78 | FT 15025 | FT 15050 | FT 15100 | FT 15150 | |

| 16 | Grey | 1 | 1.65 | FT 16025 | FT 16050 | FT 16100 | FT 16150 | |

| 18 | Green | 0.84 | 1.26 | FT 18025 | FT 18050 | FT 18100 | FT 18150 | |

| 20 | Pink | 0.6 | 0.9 | FT 20025 | FT 20050 | FT 20100 | FT 20150 | |

| 22 | Blue | 0.41 | 0.7 | FT 22025 | FT 22050 | FT 22100 | FT 22150 | |

| 25 | Red | 0.3 | 0.78 | FT 25025 | FT 25050 | FT 25100 | FT 25150 | |

One-piece integrated PP tips (P-Series):

| Gauge | Color | ID(mm) | OD(mm) | 12.7mm(1/2″) | 25.4mm(1″) | |

| 14 | Clear | 1.55 | 1.84 | CRT 14050 | CRT 14100 | |

| 15 | Clear | 1.2 | 1.64 | CRT 15050 | CRT 15100 | |

| 18 | Red | 0.84 | 1.28 | CRT 18050 | CRT 18100 | |

| 20 | Yellow | 0.6 | 1.05 | CRT 20050 | CRT 20100 | |

| 22 | Clear | 0.4 | 0.9 | CRT 22050 | CRT 22100 | |

| 25 | Clear | 0.3 | 0.8 | CRT 25050 | CRT 25100 | |

| Feature | Flexible Tips | Angled Tips | Brush Tips |

| Best For | Hard-to-reach, delicate surfaces | Confined, angled component spaces | Uniform spreading of low-viscosity fluids |

| Core Construction | All-PP flexible needle (bonded or one-piece) | Stainless-steel needle with PP or metal hub (45°/90°) | Nylon bristles with PP hub and Luer lock |

| Key Advantage | Adjustable, bendable, and cuttable for precise control | Fixed angle improves reach and precision | Gentle bristles for clean, even coverage |

| Common Applications | PCB, lab device assembly, industrial channels | Automotive, electronics assembly, industrial bonding | Electronics surface coating, lubrication, maintenance |

| Feature | Flexible Tips | Angled Tips | Brush Tips |

| Best For | Hard-to-reach, delicate surfaces | Confined, angled component spaces | Uniform spreading of low-viscosity fluids |

| Core Construction | All-PP flexible needle (bonded or one-piece) | Stainless-steel needle with PP or metal hub (45°/90°) | Nylon bristles with PP hub and Luer lock |

| Key Advantage | Adjustable, bendable, and cuttable for precise control | Fixed angle improves reach and precision | Gentle bristles for clean, even coverage |

| Common Applications | PCB, lab device assembly, industrial channels | Automotive, electronics assembly, industrial bonding | Electronics surface coating, lubrication, maintenance |

At Btektech, we engineer custom solutions for all products related to adhesives and fluid dispensing.

Our Customization Options Include:

· Physical Attributes: Size, material, and color.

· Branding: Custom packaging and logo application.

· Functional Design: Modifications based on your requirements.

To get started, simply share your basic drawings, functional specifications, or intended usage scenarios. Our engineering team will assess feasibility and collaborate with you to develop a high-performance, reliable solution.

Partner with Btektech for Precision

From initial design to final delivery, we ensure your custom solution achieves unmatched consistency. If you have a customization need, contact us today to discuss your project.

Discover similar options and compatible equipment, accessories, and consumables that pair seamlessly with this product—helping you evaluate alternatives or integrate complementary components for consistent, reliable, and precise dispensing performance.

Both types are manufactured from polypropylene (PP):

• Glue-bonded PP: Cost-efficient, enhanced flexibility, limited chemical resistance

• One-piece molded PP: Stronger needle-to-hub structure, full chemical resistance to harsh agents

Yes. The flexible PP needle can be easily trimmed to achieve precise reach and flow control inside confined or angled spaces.

Absolutely. The soft PP needle design prevents scratching or denting of delicate components, making them ideal for electronics, optics, and medical assemblies where surface protection is critical.

Suitable for a wide range of low- to medium-viscosity materials, including adhesives, lubricants, primers, coatings, activators, and certain biological fluids. The one-piece molded PP version is recommended when handling aggressive or reactive chemicals.

Yes. Both versions feature a universal Luer Lock hub, ensuring leak-free compatibility with standard syringes, valves, and automated dispensing systems.

Need More Information?

Our experts are ready to assist

Get personalized answers for your unique requirements and use cases.

Our blog is designed to help you deepen your knowledge of fluid dispensing processes, optimize your production line, and select the best components for your specific challenges. Explore articles that connect industry insights with practical solutions.

One of the most common mistakes when using dispensing tips is selecting the wrong tip size for the application.

The material of the dispensing needle is a critical consideration, as it affects compatibility with various types of adhesives.

In this ultimate guide to dispensing tips, we will explore seven types of dispensing tips, their features, and their ideal applications.