Custom Epoxy Mixing Nozzles

Contact our experts today to develop a custom-fit solution for your unique application.

Downloads

Frequently Asked Questions (FAQ)

What is a mixing nozzle and how does it function during adhesive dispensing?

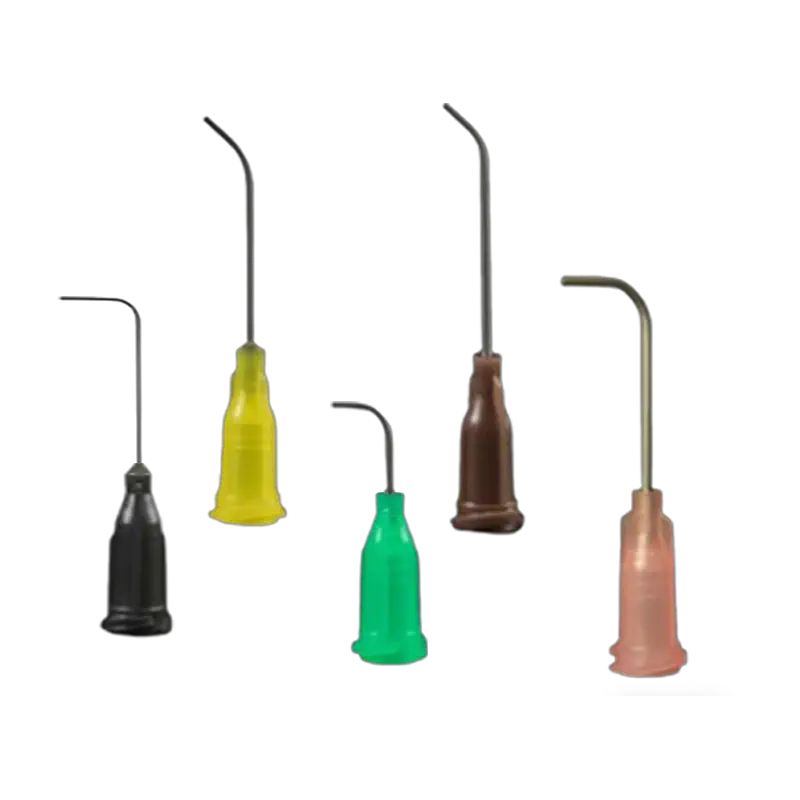

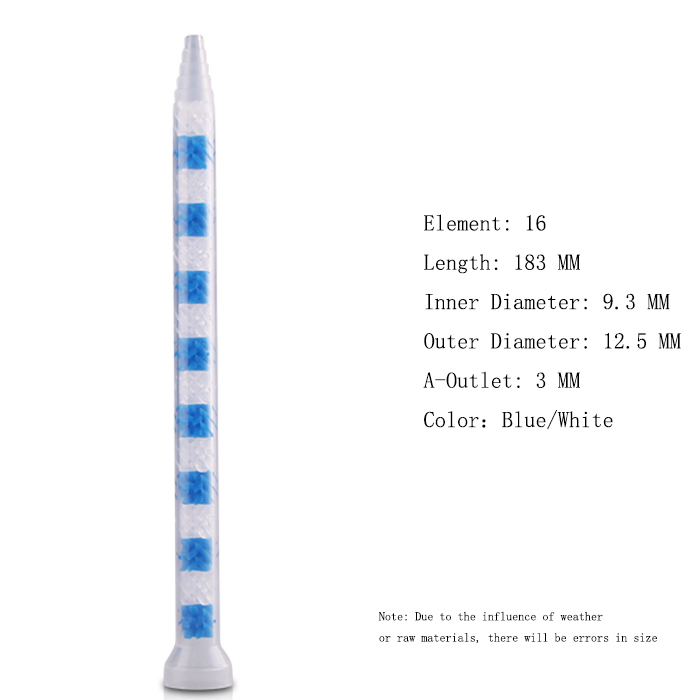

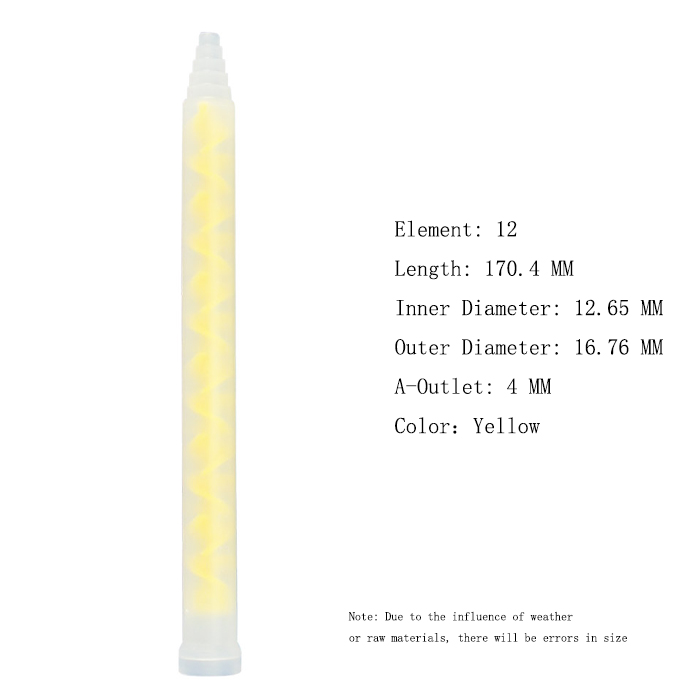

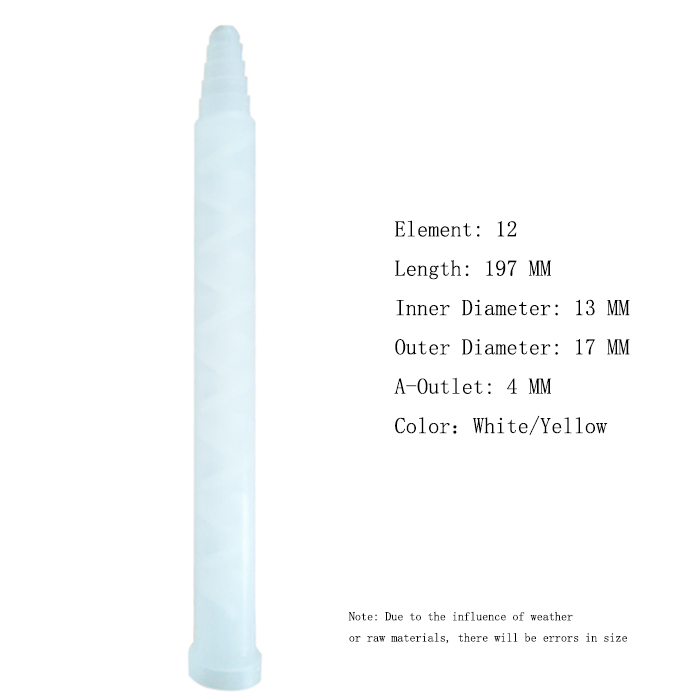

A mixing nozzle blends two-component adhesives to deliver uniform material and precise mix ratios. Static elements or dynamic rotors ensure proper mixing of epoxy, polyurethane (PU), acrylics, and other two-part adhesives across a range of viscosities. Incorrect nozzle selection can cause poor cure, inconsistent bead quality, or wasted material. Btektech offers a range of mixing nozzles engineered for reliable performance in manual and automated setups.

What is the difference between static and dynamic mixing nozzles?

The primary difference is how they blend materials: static mixing nozzles use fixed internal elements to divide and recombine fluids via flow, while dynamic nozzles utilize a motor-driven rotor for high-shear mixing. Static mixing nozzles are best for standard two-component adhesives, single-use applications, and cartridge-based manual dispensing. Dynamic nozzles are preferable for high-viscosity materials, large viscosity differences, or automated production lines such as electronics potting, automotive bonding, battery assembly, and construction sealants. Selecting the wrong type can cause incomplete mixing or inconsistent curing.

Are mixing nozzles compatible with all cartridge sizes and mix ratios?

Most mixing nozzles are compatible with standard dual cartridges from 50 ml up to 600 ml or larger, supporting common mix ratios like 1:1, 2:1, 4:1, and 10:1. Custom sizes and configurations can be produced for specific flow rates, viscosities, or equipment constraints. Using a nozzle outside its design specifications may lead to uneven mixing or excessive backpressure. Btektech provides both standard and custom nozzle solutions to match your dispensing system.

Can mixing nozzles help reduce adhesive waste in production?

Mixing occurs only inside the nozzle, so unmixed adhesive remains in the cartridge, minimizing cured material waste. This improves material utilization, lowers cost, and ensures consistent bead quality. Choosing an undersized or incompatible nozzle can reduce this benefit and increase process inefficiencies. Btektech’s nozzle designs are optimized to maximize adhesive use and reduce waste across manual and automated applications.

Are mixing nozzles reusable, and under what conditions?

Static mixing nozzles are typically single-use to prevent cross-contamination, while certain dynamic nozzles and rotors can be cleaned and reused depending on adhesive chemistry and cleaning protocol. Misusing a reusable nozzle or skipping cleaning can result in poor mix quality, contamination, or cure failure. Btektech provides guidance on nozzle reuse and cleaning to ensure reliable performance and material consistency.

Learn More About Precision Dispensing

Our blog is designed to help you deepen your knowledge of fluid dispensing processes, optimize your production line, and select the best components for your specific challenges. Explore articles that connect industry insights with practical solutions.