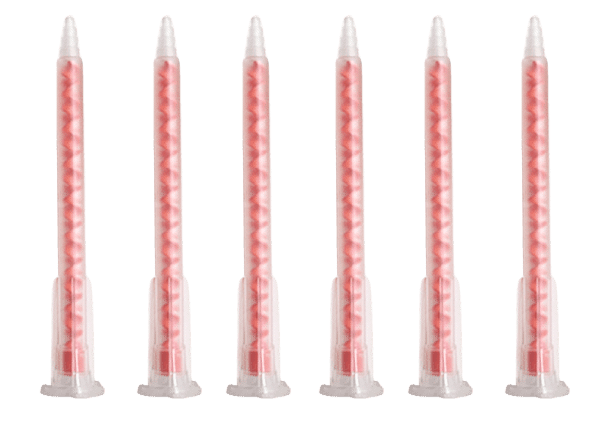

The chilly embrace of winter brings its own set of challenges when working with epoxy adhesives. One critical component often used in epoxy application is the mixing nozzle. These small but mighty tools play a significant role in ensuring proper mixing and application of epoxy, but winter conditions can pose difficulties. Here are some expert tips to help you navigate the use of epoxy mixing nozzles during colder months:

1. Warm Storage

Storing your epoxy and mixing nozzles in a warm environment before use is paramount. Cold temperatures can thicken epoxy and hinder its flow, making it challenging to mix and dispense. Keep your epoxy cartridges and mixing nozzles in a temperature-controlled room (around 70°F/21°C) for a few hours before use to maintain their ideal viscosity.

2. Preheat Cartridges

Before attaching the mixing nozzle, gently warm the epoxy cartridges. Placing them in a bucket of warm water or using a heat gun on a low setting can help soften the epoxy inside, aiding in smoother dispensing and easier mixing through the nozzle.

3. Nozzle Pre-Warming

If possible, warm the mixing nozzles slightly before use. This can prevent the epoxy from hardening prematurely inside the nozzle due to the cold. A brief exposure to warm air or dipping the nozzle in warm water (not too hot to damage the plastic) can make a significant difference.

4. Slow and Steady Mixing

When using epoxy in colder conditions, take your time with mixing. Cold temperatures can slow down the curing process, so ensure thorough mixing of epoxy components through the nozzle. Apply steady, consistent pressure on the dispensing gun to maintain a uniform flow.

5. Plan Efficiently

Minimize interruptions during application by planning your work in smaller sections. This prevents the epoxy in the mixing nozzle from sitting idle for too long, reducing the risk of premature hardening caused by the cold.

6. Insulation and Heating Devices

Consider using insulation around the cartridges and mixing nozzles during application. Additionally, portable heating devices or heat lamps in the work area can help maintain a slightly warmer temperature, ensuring smoother epoxy flow and curing.

7. Disposable Nozzles

In colder temperatures, epoxy can harden faster within the mixing nozzle, making reusability challenging. Opt for disposable mixing nozzles to avoid clogs and maintain a consistent flow. While it may generate some waste, it ensures a smoother workflow.

8. Post-Application Care

After use, properly clean the dispensing gun and dispose of used mixing nozzles promptly. Residual epoxy left in the nozzle can harden and affect future applications. Follow the manufacturer’s guidelines for cleaning and storage of the equipment.

Conclusion

Working with epoxy mixing nozzles during winter demands patience, preparation, and meticulousness. By implementing these tips, you can enhance the efficiency and quality of your epoxy applications even in cold weather conditions. Remember, a little extra care during winter can go a long way in ensuring successful epoxy projects.