1. Introduction

The foundation of a successful custom hearing aid fitting lies in the accuracy of the ear impression—a precise three-dimensional replica of the ear canal and pinna. In audiology practice, this process involves injecting a pliable silicone material to capture the ear’s unique anatomy, ensuring optimal acoustic sealing, comfort, and performance for devices such as behind-the-ear (BTE) aids, receiver-in-the-canal (RIC) instruments, earmolds, and protective solutions.

Ear impressions serve as the blueprint for fabricating custom products, from hearing aids to musician earplugs and swim molds. A well-executed impression minimizes acoustic feedback, enhances retention, and promotes long-term patient adherence. However, achieving consistency requires both scientific precision and skilled technique, particularly given the ear canal’s dynamic nature and individual variations.

Btektech’s Impression Guns represent a significant advancement in this essential procedure. This precision dispensing tool, designed as a manual model, facilitates the controlled delivery of dual-component vinylpolysiloxane (VPS) silicone via cartridges, promoting uniform mixing and reducing procedural errors. Tailored for ear impression, it streamlines workflows while upholding the highest standards of accuracy.

This article examines the importance of ear impressions, outlines a structured protocol, addresses common challenges, and highlights the role of Btektech’s Impression Gun in elevating professional outcomes. For clinics seeking to optimize impression-taking efficiency and interested in our Impression Gun, further details are available by contacting us

2. The Importance of Ear Impressions

Ear impressions form the cornerstone of custom audiology solutions, directly influencing the fit, function, and satisfaction of fabricated devices. The process demands a balance of anatomical knowledge and procedural rigor to replicate the ear’s contours accurately, including the cartilaginous and bony portions of the canal and key landmarks in the pinna.

Step-by-Step Protocol for Ear Impressions

The ear impression procedure typically spans 10-15 minutes and integrates clinical assessment with material application. The following outline reflects established best practices in audiology:

- Patient Assessment and Ear Examination: Conduct a comprehensive history review, noting conditions such as diabetes, anticoagulant use, or prior ear surgeries that may pose risks. Employ a video otoscope to inspect the canal for cerumen impaction, infections, perforations, or anomalies like exostoses. Remove accessible debris if appropriate; otherwise, refer for medical clearance.

- Otoblock Placement: Select a cotton otoblock for its malleability and reduced abrasiveness, particularly in the sensitive bony region. Lubricate with a water-based agent and, using a curette or ear light, advance it beyond the second canal bend toward the tympanic membrane. Brace the hand against the patient’s head for stability, then verify placement otoscopically to confirm a complete seal without gaps.

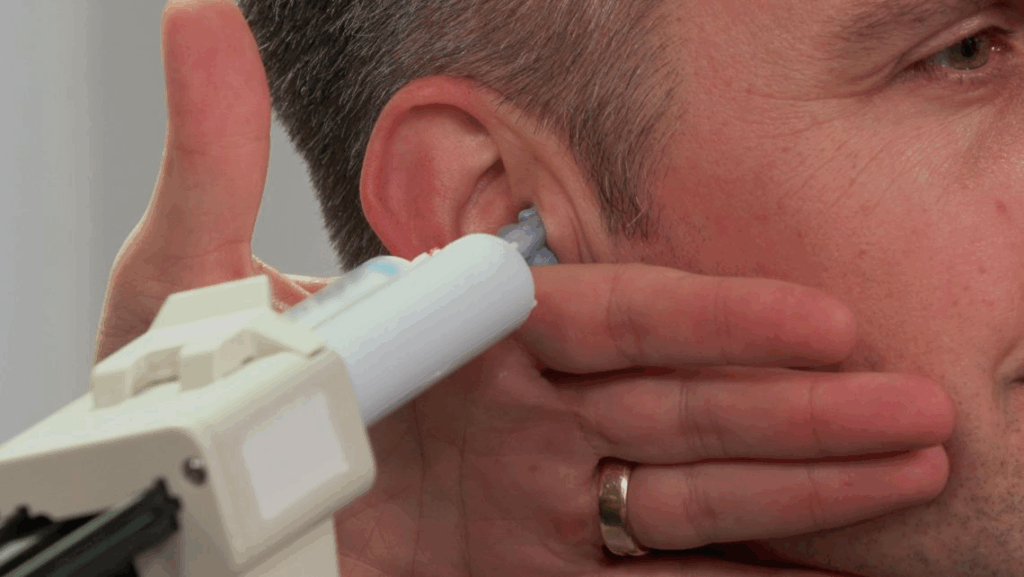

- Material Injection: Utilize VPS silicone for its dimensional stability and minimal shrinkage. Insert the delivery tip approximately 6 mm into the canal and dispense material steadily, allowing it to flow along the walls. Ensure comprehensive coverage of the concha, antihelix, tragus, helix, and triangular fossa to preserve anatomical fidelity.

- Curing and Removal: Allow 3-8 minutes for polymerization, testing firmness with a fingernail. Instruct the patient to perform subtle jaw movements to release the seal, then gently manipulate the pinna upward and backward while rotating the impression toward the nose. Re-examine the ear canal to confirm no residual material.

- Impression Evaluation: Assess for completeness, including canal depth beyond the second bend, absence of voids, and intact peripheral landmarks. Document any irregularities for the laboratory to facilitate precise fabrication.

This protocol underscores the need for meticulous execution, as the ear canal’s narrow, sensitive structure tolerates little margin for error.

The Critical Role of Ear Impressions in Audiology

Precision in ear impressions directly correlates with the efficacy of custom devices. By replicating the canal’s dual bends and dynamic expansions—such as those induced by jaw movement—impressions enable laboratories to produce shells or molds that achieve acoustic sealing between the first and second bends, thereby mitigating feedback and enhancing sound quality.

Industry data from MarkeTrak surveys consistently identifies clinician proficiency in impression-taking as a key driver of patient satisfaction. High-quality impressions contribute to devices that are comfortable, secure, and free from occlusion effects, reducing rejection rates and supporting ancillary revenue streams from products like custom hearing protection and swim molds.

Beyond hearing aids, applications extend to specialized solutions, including in-ear monitors for musicians and noise-attenuating earplugs for industrial settings. Moreover, superior impressions correlate with 20-30% lower remake rates, according to laboratory benchmarks, thereby conserving clinic resources and enhancing operational efficiency.

In an era of predominantly non-custom hearing technologies, maintaining expertise in impression-taking preserves versatility and positions practices as comprehensive providers of personalized audiology care.

Challenges in Traditional Ear Impression Methods

Despite their foundational importance, conventional techniques present notable obstacles. Manual mixing of powder-liquid or condensation-cure materials often results in shrinkage exceeding 3%, distorting the final mold. Syringe-based injection risks air entrapment and uneven distribution, particularly in curved or narrow canals, leading to voids that compromise acoustic integrity.

These issues not only increase remake frequencies but also heighten patient discomfort during deep insertions and elevate material waste. Precision-engineered tools address these limitations by ensuring consistent material properties and controlled delivery. Btektech’s Impression Gun, for instance, exemplifies this evolution through automated mixing capabilities, consistent ratio accuracy, and stringent control over plunger precision, eliminating procedural variability.

| Common Challenges in Ear Impressions | Clinical Impact | Mitigation with Advanced Tools |

|---|---|---|

| Air bubbles or voids from inconsistent mixing | Increased remakes (20-30% incidence) and feedback issues | Automated dual-component mixing for uniform consistency |

| Uneven flow in syringe delivery | Material waste and incomplete anatomical capture | Cartridge-based dispensing for precise, controlled injection |

| Canal distortion from jaw movement | Reduced device retention and comfort | Support for open- or closed-jaw protocols without compromise |

| Sensitivity in bony canal regions | Patient discomfort during procedure | Gentle, pressure-regulated material flow |

3. The Role of the Impression Gun in Ear Impressions

The Impression Gun serves as a pivotal instrument in modern audiology, transforming the ear impression process from a labor-intensive task into a streamlined, reliable procedure. Btektech’s models, such as the 50 ml Cartridge Impression Gun, accommodate manual operation and are optimized for dual-chamber VPS cartridges, delivering materials with exacting control.

Application of the Impression Gun

Following otoscopic examination and otoblock insertion, load the appropriate cartridge into the gun. Position the mixing tip 6 mm within the canal aperture, applying a braced technique against the patient’s head. Activate the gun to dispense material gradually, observing backflow to confirm canal filling before retracting the tip. Extend coverage to the concha, helix, tragus, and antihelix, incorporating a bite block if an open-jaw impression is indicated for feedback-sensitive applications.

Polymerization occurs within 3-5 minutes, after which the impression is removed via controlled rotation. This method ensures comprehensive landmark capture while minimizing procedural time.

Advantages of Btektech’s Impression Gun

Btektech’s Impression Gun addresses key limitations of traditional methods through advanced engineering. Automated mixing via the disposable tip prevents air incorporation, yielding void-free impressions essential for accurate laboratory replication.

The tool’s lightweight construction and ergonomic design facilitate prolonged use without fatigue. Rigorous quality control of raw materials and precision components ensures consistent performance, while extensive testing across various materials guarantees compatibility with client-specific requirements. This adaptability supports a wide range of applications, from standard hearing aid shells to specialized protective devices, enhancing precision and efficiency in high-volume practices.

4. Conclusion and Call to Action

Ear impressions remain indispensable for fabricating high-performance custom audiology products, demanding precision to capture anatomical nuances and ensure patient-centered outcomes. By mitigating common challenges such as voids and inconsistent mixing, tools like Btektech’s Impression Gun enhance procedural accuracy, efficiency, and satisfaction.

Audiology professionals and device suppliers are encouraged to evaluate these solutions for integration into clinical protocols. Visit Btektech for product specifications, demonstrations, and consultation on optimizing impression-taking workflows. Implementing such advancements can significantly elevate practice standards and patient care.