Have you ever experienced production stoppages caused by a clogged adhesive dispensing needle or struggled with inconsistent bead shapes that affect product quality?

In modern industrial adhesive dispensing, the needle may appear small, but it plays a vital role in ensuring precision, consistency, and efficiency. Selecting the right one can make the difference between smooth production and costly rework.

This guide will help you understand how to choose the optimal adhesive dispensing needle based on material, gauge, length, and tip configuration, the four key parameters that directly impact application precision, flow control, and adhesive compatibility.

Choosing the right needle goes beyond specifications; it also depends on your application requirements, adhesive type, and cost-performance balance. By aligning these factors, you can achieve stable performance, reduce waste, and improve throughput.

At Btektech, we specialize in helping manufacturers strike this balance. From metal to plastic and specialty materials, our comprehensive range of dispensing tips — backed by expert technical support and tailored solutions — ensures every drop of adhesive lands exactly where it should.

➡ Contact our specialists today to find the perfect needle for your application.

Needle Material: Compatibility and Performance

The material of an adhesive dispensing needle plays a crucial role in its durability, chemical resistance, and adhesive compatibility. Using the wrong needle can cause clogging, inconsistent bead formation, or even damage to delicate components.

In contrast, the right adhesive dispensing needle ensures precise material placement, reduces rework, and improves production efficiency.

Each material type — metal, plastic, or specialty — offers unique advantages tailored to specific adhesive viscosities and application environments.

Understanding your process requirements is the first step toward achieving flawless dispensing performance.

Metal dispensing Tips

Metal dispensing tips are valued for their superior durability, mechanical strength, and precision. They are often the preferred choice for demanding, high-volume production environments.

At Btektech, our metal tips primarily feature two distinct construction types, each with unique benefits:

· Stainless-Steel Needle with Polypropylene (PP) Hub: This hybrid design is used in our Blunt Tip Needles (General Purpose Tips), Angled Dispensing Tips, and Oval Dispensing Tips. It combines a precision stainless-steel needle for smooth fluid flow with a lightweight, cost-effective PP hub, offering an excellent balance of performance and value for standard dispensing applications.

· All-Metal Construction: Featured in our Stainless Steel Dispensing Tips and Stainless Steel Precision Nozzles. It delivers exceptional structural integrity, making it ideal for high-pressure, high-temperature, and high-speed automated dispensing where maximum mechanical strength is critical.

Advantages of Metal dispensing Tips

· Smooth, Clog-Resistant Flow: Precision-machined, burr-free stainless-steel needles ensure consistent fluid path and accurate material placement.

· Two Options for Different Needs: Choose the cost-effective PP Hub for standard use, or the All-Metal version for superior mechanical strength and temperature resistance.

· Reliable in Demanding Conditions: Both types offer excellent dimensional stability for precise dispensing of adhesives, solvents, and oils.

Best For:

High-performance industries such as electronics assembly (SMT, PCB), automotive manufacturing, and industrial automation. PP Hub tips are ideal for general precision tasks, while All-Metal tips are essential for high-speed automation, high-pressure dispensing, and applications requiring thermal and mechanical resilience.

Plastic Dispensing Needles

Plastic dispensing needles provide a lightweight, cost-effective, and disposable solution ideal for a wide range of precision tasks, while protecting sensitive surfaces from scratches.

Our plastic needle range includes:

· Tapered Tips: Made from high-quality polypropylene (PP), these tips are designed for smooth, controlled flow of medium- to high-viscosity materials like epoxies and silicones, with minimal dripping.

· Flexible Dispensing Tips: Also engineered from polypropylene (PP), these tips are highly bendable and can be trimmed to custom lengths for accessing confined or angled spaces without risking surface scratches.

Advantages of Plastic Dispensing Needles

· Scratch-Free Performance: The soft PP material prevents abrasion or damage to delicate components, coatings, and lenses.

· Chemical Resistance & Material Options: Standard PP are suitable for general use, while the one-piece integrated (P-Series) Flexible Tip provides superior resistance for harsher fluids.

· Adaptable & Cost-Effective: The flexible and trimmable nature of PP needles allows for customization, while their disposability helps prevent cross-contamination.

Best For:

Applications requiring flexibility, surface protection, and access to tight spaces, including electronics & PCB assembly, medical device assembly, and general industrial manufacturing on sensitive surfaces.

Specialty Material Needles

For challenging fluids and unique application methods, specialty material tips deliver targeted performance that standard needles cannot match.

Btektech’s specialty range includes:

· PTFE Tips: These integrate a stainless-steel outer cannula with an inner smooth PTFE lining. The PTFE liner extends beyond the steel tip, creating a non-stick outlet zone that prevents curing and clogging when dispensing reactive adhesives like cyanoacrylates (instant adhesives).

· Brush Dispensing Tipss: Featuring durable, oil-resistant nylon bristles and a universal Luer lock, these tips are designed for the smooth, even application of low-viscosity materials.

Advantages of Specialty Material Needles

· Advanced Clog-Resistant Design: The non-stick PTFE liner is specifically engineered to prevent blockage from fast-curing adhesives, ensuring process reliability and reducing downtime.

· Precise and Even Fluid Distribution: The soft nylon bristles of brush tips enable controlled, uniform coverage on complex geometries and sensitive surfaces, reducing waste.

· Exceptional Chemical Durability: The PTFE lining offers excellent resistance to a wide range of aggressive chemicals and solvents, maintaining fluid integrity.

Best For:

Demanding applications involving reactive chemicals (e.g., cyanoacrylates, anaerobics) in electronics and automotive assembly, or tasks requiring even coating rather than dot/line dispensing in general industrial and maintenance settings.

Needle Gauge: Size Reference Guide

The gauge (G) of a dispensing needle determines its inner diameter, which directly affects the adhesive flow rate. Generally, the larger the gauge number, the thinner the needle — both the outer and inner diameters change accordingly, along with the wall thickness.

Understanding these dispensing needle sizes is essential for selecting the correct gauge, which is crucial for achieving consistent adhesive output, minimizing material waste, and maintaining stable dispensing pressure.

For quick selection and comparison, the Dispensing Tip Gauge Chart below helps you identify the ideal gauge size based on adhesive viscosity and specific application needs.

Gauge (G) | ID (mm) | Typical Viscosity Range | Common Applications |

10 – 14G | 2.8 – 1.65 | High viscosity | Epoxy resin, thermal paste, silicone, grease |

15 – 18G | 1.43 – 0.84 | Medium–high viscosity | UV adhesive, crystal glue, solder paste |

19 – 22G | 0.71 – 0.41 | Medium viscosity | Epoxy, thick cyanoacrylate (super glue) |

23 – 26G | 0.33 – 0.25 | Low–medium viscosity | Flowable cyanoacrylate, ink, flux |

27 – 34G | 0.21 – 0.06 | Low viscosity | Water-like fluids, solvents, lubricants, reagent dispensing |

Selection Tip: Always test your adhesive flow using the intended gauge under actual production conditions. Factors such as adhesive viscosity, temperature, and application pressure can all influence performance and consistency.

➡ Want more detailed specifications?

➡ [Download the complete Btektech Dispensing Needle Data Sheet] — featuring individual specifications for each needle type.

Needle Length: Reach and Flow Control

The length of a dispensing needle directly impacts both

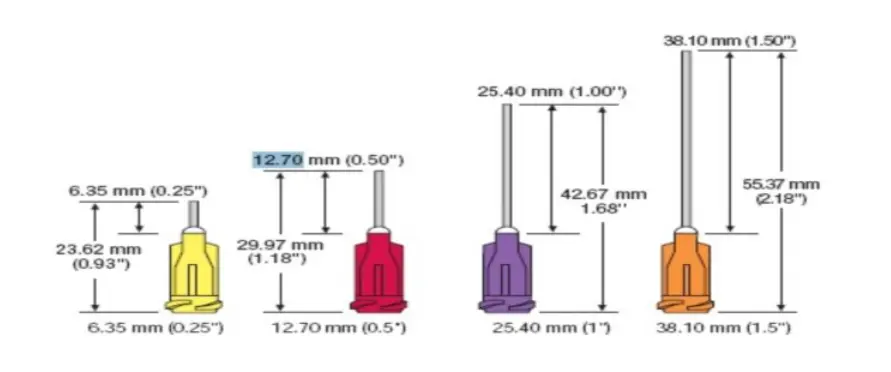

The length of a dispensing needle directly impacts both application precision and reach. Shorter needles provide greater control for fine, repeatable deposits, while longer needles allow easy access to recessed or hard-to-reach areas.

It’s important to note that longer needles increase internal flow resistance due to greater friction. To maintain consistent adhesive flow and prevent stringing or delays, simply adjust the dispensing pressure or feed rate accordingly.

Common industry lengths include:

·Short (6.35 mm / 1/4”): Provides maximum control for precision bonding, dot placement, and micro-dispensing applications.

·Medium (12.7 mm / 1/2”): A versatile choice suitable for most general manufacturing and assembly processes.

·Long (25.4 mm / 1”): Ideal for cavity filling or applications involving recessed components.

·Extra Long (38.1 mm / 1-1/2”): Best suited for deep cavities or areas requiring extended reach through narrow openings.

Contact Btektech to discuss your specific application requirements. Our technical team will help you determine the optimal needle length for your production setup and provide tailored solutions that match your adhesive and coating needs.

Needle Tip Configurations: Shapes and Application Results

Adhesive dispensing needles come in a variety of tip configurations, each engineered to meet specific application needs. The shape of the needle’s outlet directly influences the form, width, and spread of the adhesive bead. Common designs include round, angled, and flat/oval openings, each providing distinct coating results depending on the material and workpiece geometry.

Below is a brief overview of five common tip configurations and opening shapes. For a more in-depth comparison of all available types, visit our blog: The Ultimate Guide to Dispensing Tips.

Blunt Dispensing Needles:

Blunt tips are the most versatile and widely used type. Their non-sharp openings allow for safe, consistent adhesive flow without damaging sensitive or sensitive components.

Tapered Tips

Tapered tips feature a gradually narrowing design that minimizes back pressure and enables smooth, drip-free dispensing of high-viscosity materials. These tips are also available in UV-blocking and anti-static variants for specialized applications.

Angled Dispensing Needles

Angled tips (commonly 45° or 90°) offer enhanced accessibility in confined or obstructed areas. They are ideal for reaching around tall components or working inside narrow enclosures.

Flexible Dispensing Needles

Flexible tips can be bent, shaped, or trimmed to the desired length, offering exceptional adaptability for applications involving irregular or curved surfaces.

Oval Dispensing Tips

Oval tips have an elongated, flat orifice that produces wide, uniform ribbons of adhesive, sealant, or paste. This design minimizes overlap and ensures even, consistent coating coverage.

Needle Selection: Key Application Considerations

After understanding how needle material, gauge, length, and tip configuration influence dispensing performance, it’s important to evaluate a few additional factors before making your final selection.

Choosing the right adhesive dispensing needle depends not only on technical specifications but also on your application requirements, adhesive type, and cost-performance balance.

Application Requirements

Every dispensing process comes with unique performance demands:

·Fine-pitch or micro-bonding applications require small-diameter needles for precise, controlled deposits.

·Gap filling or structural bonding tasks benefit from larger orifices that deliver higher adhesive volumes quickly.

Before selecting a needle, clearly define your application type, flow rate, and desired bead shape. Matching the needle size and geometry to your dispensing target area ensures cleaner results, consistent performance, and optimal material usage.

Adhesive Type and Chemical Properties

The adhesive’s viscosity and chemical composition directly determine the most suitable needle material and size.

Viscosity and Flow Control:

· Low-Viscosity Adhesives (e.g., cyanoacrylates, anaerobics) require tips that ensure a stable, clog-resistant flow. PTFE Tips are specifically designed for such fluids, as their inner PTFE lining provides a non-stick outlet zone that prevents curing and blockage. For general-purpose low-viscosity fluids, Blunt Tip Needles with their precision-bore stainless steel also offer consistent, clog-resistant performance.

·High-Viscosity Adhesives (e.g., epoxies, silicones, sealants) require larger inner diameters to reduce back pressure and maintain consistent flow. Tapered Tips are especially effective for these materials, as their gradual internal profile promotes smoother delivery. For applications requiring a flat, wide bead, Oval Dispensing Tips are engineered to deliver a smooth, controlled ribbon of high-viscosity materials.

Chemical Compatibility:

· For corrosive, reactive, or aggressive chemical fluids, material compatibility is critical. PTFE Tips offer exceptional chemical resistance. For applications where chemical resistance is needed alongside flexibility, the one-piece integrated Flexible Dispensing Tips (P-Series) provide a superior chemical-resistant, scratch-free option.

Curing Sensitivity:

· For light-sensitive adhesives like UV-curables, proper needle selection helps prevent premature curing. Tapered Tips are available in UV-blocking black polypropylene versions that effectively shield light-sensitive materials during dispensing. Using chemically compatible tips and ensuring clean, clog-free dispensing with options like PTFE Tips for instant adhesives prevents contamination and ensures stable performance.

➡ If you’re unsure which adhesive dispensing needle best suits your application, contact our sales experts today. We’ll help you identify the optimal solution for consistent, reliable performance.

Cost-Effectiveness and Productivity Balance

While high-precision needles may have higher initial costs, they offer superior durability and accuracy, reducing rework, waste, and downtime over time.

·For high-volume automated assembly, metal dispensing tips offer exceptional mechanical strength and temperature resistance, minimize tool changes and maintenance interruptions.

·For manual or prototype applications, plastic dispensing needles remain a cost-effective option.

The key is to find the right balance between performance, durability, and cost, ensuring consistent results and maximum return on investment.

Conclusion

Choosing the right adhesive dispensing needle is the foundation of achieving flawless production performance. As discussed, this decision depends on the careful integration of needle material, gauge size, length, and tip configuration — each influencing how your adhesive flows, cures, and bonds.

A well-matched needle ensures consistent deposition, minimal waste, and greater process stability, transforming adhesive dispensing from a routine step into a competitive advantage.

Yet precision doesn’t stop at component selection — it extends to partnership. A reliable supplier provides not only quality products but also engineering expertise, process guidance, and customized solutions that help you optimize your entire operation.

At Btektech, we combine advanced manufacturing technology with deep application knowledge to deliver precision dispensing solutions tailored to your exact production needs.

Whether you require metal tips, plastic needles, or custom specialty designs, our team ensures compatibility, consistency, and long-term reliability.

Your Path to Precision Starts Here

Stop guessing — start optimizing. Turn these insights into measurable results for your production line.

·Get a Personalized Recommendation: Speak directly with our technical experts.

·Test Before You Invest: Request complimentary samples to validate performance.

·Solve a Unique Challenge: Ask about our custom capabilities.