In the realm of precision mixing and dispensing, static mixing nozzles emerge as unassuming yet indispensable tools across multiple industries. These nozzles play a crucial role in achieving homogenous blends of materials, facilitating processes in diverse applications, from manufacturing to construction.

Understanding Static Mixing Nozzles

Static mixing nozzles are devices designed to homogenize two or more materials by combining them as they pass through a series of fixed elements within the nozzle. These elements typically consist of helical or perforated elements arranged in a specific configuration to ensure thorough mixing without the need for additional mechanical agitation.

Functionality and Operation

The design of static mixing nozzles promotes the efficient blending of materials by utilizing their inherent flow characteristics. As substances pass through the nozzle, the elements inside induce turbulence and controlled mixing, effectively combining the components without the need for moving parts or external energy sources.

Applications Across Industries

The versatility of static mixing nozzles makes them invaluable in various sectors:

-

Adhesives and Sealants:

In bonding and sealing applications, these nozzles ensure a consistent mix of adhesives and sealants, enhancing product performance and reliability.

-

Chemical Processing:

Industries dealing with chemicals benefit from static mixing nozzles for precise blending of reactive substances, leading to improved product quality and reduced waste.

-

Construction and Infrastructure:

From concrete to coatings, static mixing nozzles aid in dispensing and blending materials for construction purposes, ensuring uniformity and strength in the final product.

Advantages of Static Mixing Nozzles

- Precision: They enable accurate and controlled mixing ratios.

- Cost-Effective: Eliminate the need for additional mixing equipment.

- Reduced Waste: Ensures minimal material wastage.

- Ease of Use: Simple and low-maintenance design.

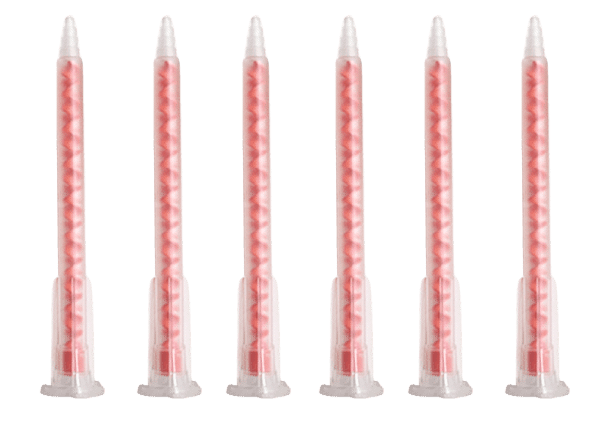

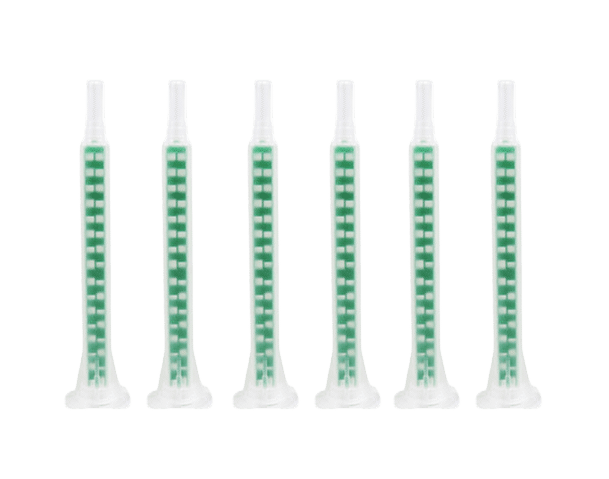

Types of Static Mixing Nozzles

Several types of static mixing nozzles exist, each tailored to specific applications:

- Helical Mixing Elements: Utilize twisted elements for efficient blending.

- Rectangular Elements: Employ rectangular-shaped elements to achieve mixing.

- Disposable vs. Reusable Nozzles: Available options based on intended use and material compatibility.

Conclusion

Static mixing nozzles stand as unsung heroes in various industries, silently contributing to the efficiency, precision, and quality of processes. Their ability to effortlessly blend materials without complex machinery makes them indispensable tools, streamlining operations and ensuring consistent results across applications.

Whether in adhesive dispensing, chemical processing, or construction, these unassuming devices continue to play a vital role in shaping the modern manufacturing landscape.