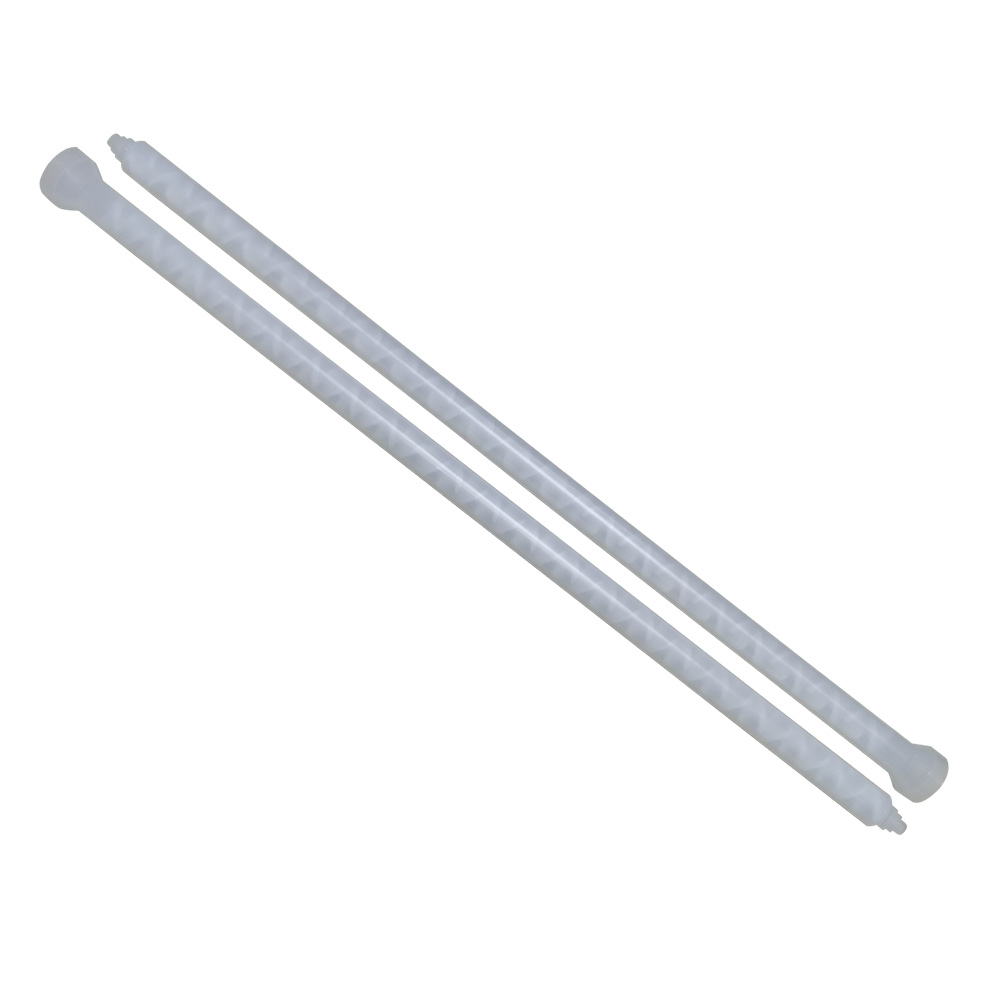

In epoxy dispensing systems, the role of epoxy mixing nozzles is crucial for achieving precise and controlled application. These specialized nozzles are designed to facilitate the thorough blending of epoxy components and deliver a homogeneous mixture directly at the dispensing point. Let’s explore how epoxy mixing nozzles work in conjunction with dispensing systems to enhance precision and efficiency.

Integration with Dispensing Systems:

Epoxy mixing nozzles are designed to seamlessly integrate with dispensing systems, ensuring smooth and efficient operation. They can be easily attached to various types of dispensing equipment, such as metering pumps, cartridges, or pneumatic dispensers. This compatibility allows businesses to incorporate epoxy mixing nozzles into their existing dispensing processes without the need for significant modifications or investments in new equipment.

Efficient Mixing at the Point of Dispensing:

With epoxy mixing nozzles, the mixing of resin and hardener occurs directly within the nozzle itself. This eliminates the need for separate mixing equipment or manual blending. By combining the epoxy components precisely at the dispensing point, the nozzles ensure a homogeneous mixture with consistent properties throughout the dispensing process. This efficient mixing mechanism saves time, reduces waste, and enhances the overall quality of the applied epoxy.

Precise and Controlled Dispensing:

Achieving precise and controlled epoxy dispensing is essential for accurate application. Epoxy mixing nozzles provide a controlled flow rate and an even distribution of the epoxy mixture. This allows operators to apply epoxy in the desired quantity and location, minimizing waste and reducing the need for rework. The precise control offered by these nozzles ensures that the epoxy is dispensed exactly where it is needed, improving overall efficiency and product quality.

Disposable and Cost-Effective Solution:

Epoxy mixing nozzles are often designed as disposable components. This eliminates the need for time-consuming cleaning and maintenance, as well as the risk of cross-contamination between different epoxy formulations. Disposable nozzles offer a cost-effective solution by eliminating the expenses associated with cleaning, solvent usage, and labor required for nozzle maintenance. The disposable nature of these nozzles also contributes to a more streamlined and efficient dispensing process.

Versatile Applications:

Epoxy mixing nozzles find applications in a wide range of industries, including automotive, aerospace, electronics, construction, and more. Whether it’s bonding, sealing, encapsulating, or coating, these nozzles enable precise and reliable epoxy dispensing for various tasks. Their versatility allows professionals to use them for different types of epoxy materials, viscosities, and application requirements, making them an indispensable tool for achieving high-quality results across diverse industries.

Conclusion

In conclusion, epoxy mixing nozzles play a vital role in dispensing systems by enabling precise and controlled epoxy application. Their integration with dispensing equipment, efficient mixing at the point of dispensing, precise control over flow rate and distribution, disposable nature, and versatility in applications make them indispensable tools for enhancing precision and efficiency in epoxy dispensing processes. By incorporating epoxy mixing nozzles into their dispensing systems, businesses can achieve consistent and reliable epoxy application, leading to improved product quality and customer satisfaction.