Two-part adhesives are widely used in various industries for bonding applications that require exceptional strength and durability. These adhesives consist of two components that need to be thoroughly mixed before application to ensure proper curing and optimal adhesive performance. Epoxy mixer nozzles play a crucial role in facilitating the accurate and efficient mixing of two-part adhesives, enabling users to achieve consistent results and maximize adhesive bond strength.

The Importance of Effective Mixing:

Proper mixing is essential for two-part adhesives to achieve their desired properties. These adhesives typically consist of a base resin and a hardener or curing agent. The two components must be thoroughly mixed in the correct ratio to initiate the chemical reaction that leads to curing. Inadequate mixing can result in weak bonds, reduced adhesive performance, and compromised product quality.

Mixer Nozzles: The Key to Efficient Mixing:

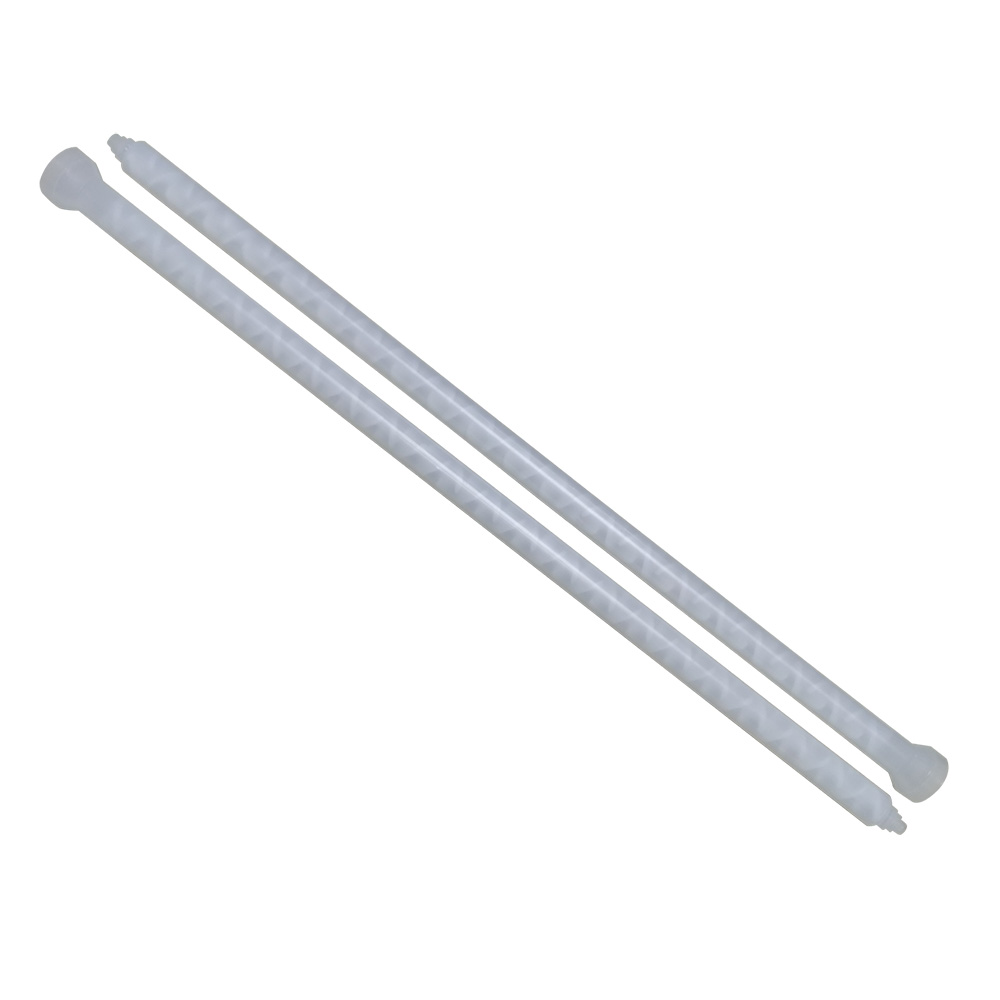

Mixer nozzles are designed specifically to address the challenges associated with mixing two-part adhesives. These nozzles are typically used in conjunction with dual-cartridge dispensing systems, which store the two adhesive components separately and mix them at the point of application. The primary function of mixer nozzles is to ensure thorough blending of the two components, promoting homogeneity and uniformity in the adhesive mixture.

Key Advantages of Mixer Nozzles:

-

Homogeneous Mixing:

Mixer nozzles employ a unique design that incorporates static mixing elements within the nozzle body. These elements create turbulent flow patterns, promoting rapid and effective mixing of the two adhesive components. This results in a homogenous blend with consistent properties throughout the adhesive application.

-

Controlled Ratio:

Maintaining the correct ratio of base resin to hardener is critical for the adhesive’s performance. Mixer nozzles are engineered to ensure accurate and consistent ratio control, preventing inconsistencies in curing and adhesive strength. This precise ratio control is achieved by the geometrical configuration of the mixing elements within the nozzle.

-

Elimination of Manual Mixing:

In the past, users had to manually mix two-part adhesives using spatulas or other tools. This manual process was time-consuming and prone to human error. Mixer nozzles eliminate the need for manual mixing, saving time and improving efficiency. They enable direct dispensing of thoroughly mixed adhesives, streamlining the application process.

-

Reduced Waste:

Mixer nozzles contribute to waste reduction by minimizing adhesive material left in the cartridge. The static mixing elements within the nozzle ensure that the adhesive is fully expelled, leaving minimal residual material in the cartridge. This reduces material waste and lowers operational costs.

-

Versatility:

Mixer nozzles are available in various sizes and configurations to suit different applications and adhesive viscosities. They can be tailored to meet specific requirements, ensuring optimal performance and compatibility with different dispensing systems.

Conclusion:

Mixer nozzles are indispensable tools for achieving efficient and reliable mixing of two-part adhesives. By promoting thorough blending, accurate ratio control, and waste reduction, these nozzles significantly enhance adhesive performance, bond strength, and overall product quality. Industrial applications spanning automotive, aerospace, electronics, construction, and more rely on mixer nozzles to streamline their adhesive processes, making them a valuable asset for any organization working with two-part adhesives.