Dual cartridge dispensing syringe barrel for silicone

One of the key features of dispensing syringe barrels is their ability to maintain the correct ratio of the two components throughout the dispensing process.

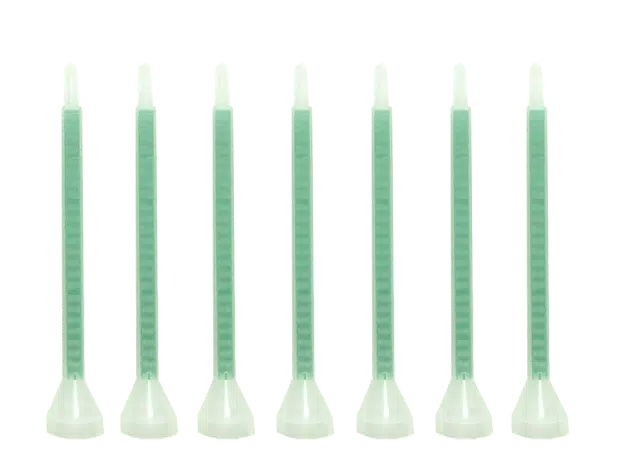

The static mixing nozzle for silicone

Static mixing nozzles are commonly used to apply silicone sealants and adhesives for sealing and bonding applications.

The dual cartridge syringe barrel in 2k dispensing system

Dual cartridge syringe barrels are typically made of high-quality plastic or metal to ensure compatibility with a wide range of materials.

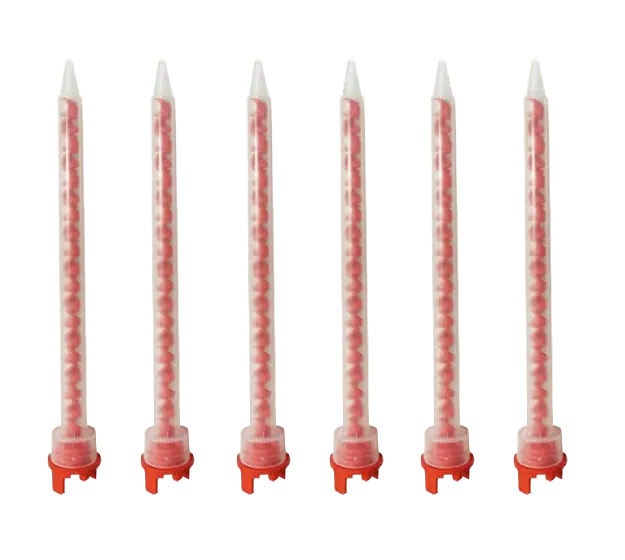

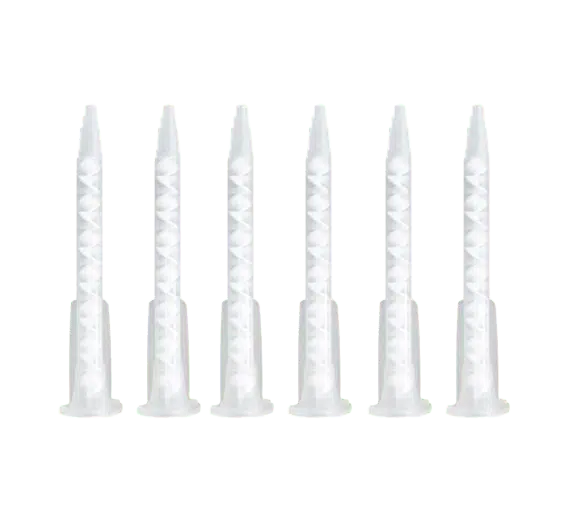

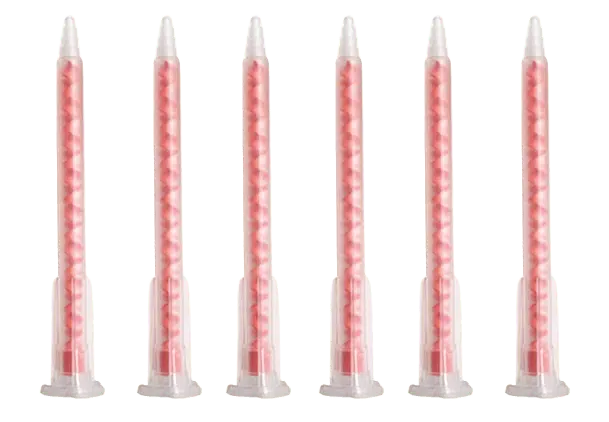

The epoxy mixing nozzle in 2k dispensing system

Epoxy mixing nozzles play a critical role in 2K dispensing systems by facilitating the thorough mixing of two-component materials before they are applied.

The Static Mixer for Polyurea

Static mixers offer a range of benefits that make them an ideal choice for mixing Polyurea in industrial applications.

Are dispensing syringe guns friendly to beginner

For beginners, learning to use a syringe gun effectively may require some practice and familiarization with its components and operation.

The Maintenance of Syringe Guns

Regular cleaning of your syringe gun is crucial to prevent clogs and ensure smooth operation. Residual adhesives and contaminants can build up over time, affecting the gun’s performance.

Common issues about using dispensing syringe barrel

Air entrapped in a syringe barrel is a common issue that can adversely affect dispensing performance. When air is present, it can lead to inconsistent dispensing, blockages, or even material waste.

Common issues about using epoxy mixing nozzle

Use the correct size and type of mixing nozzle for the adhesive being dispensed to ensure proper flow and reduce the risk of clogging.

The best packing solution of epoxy gun

Adding a layer of bubble wrap or air cushions inside the box can provide additional cushioning and protection for manual epoxy guns.