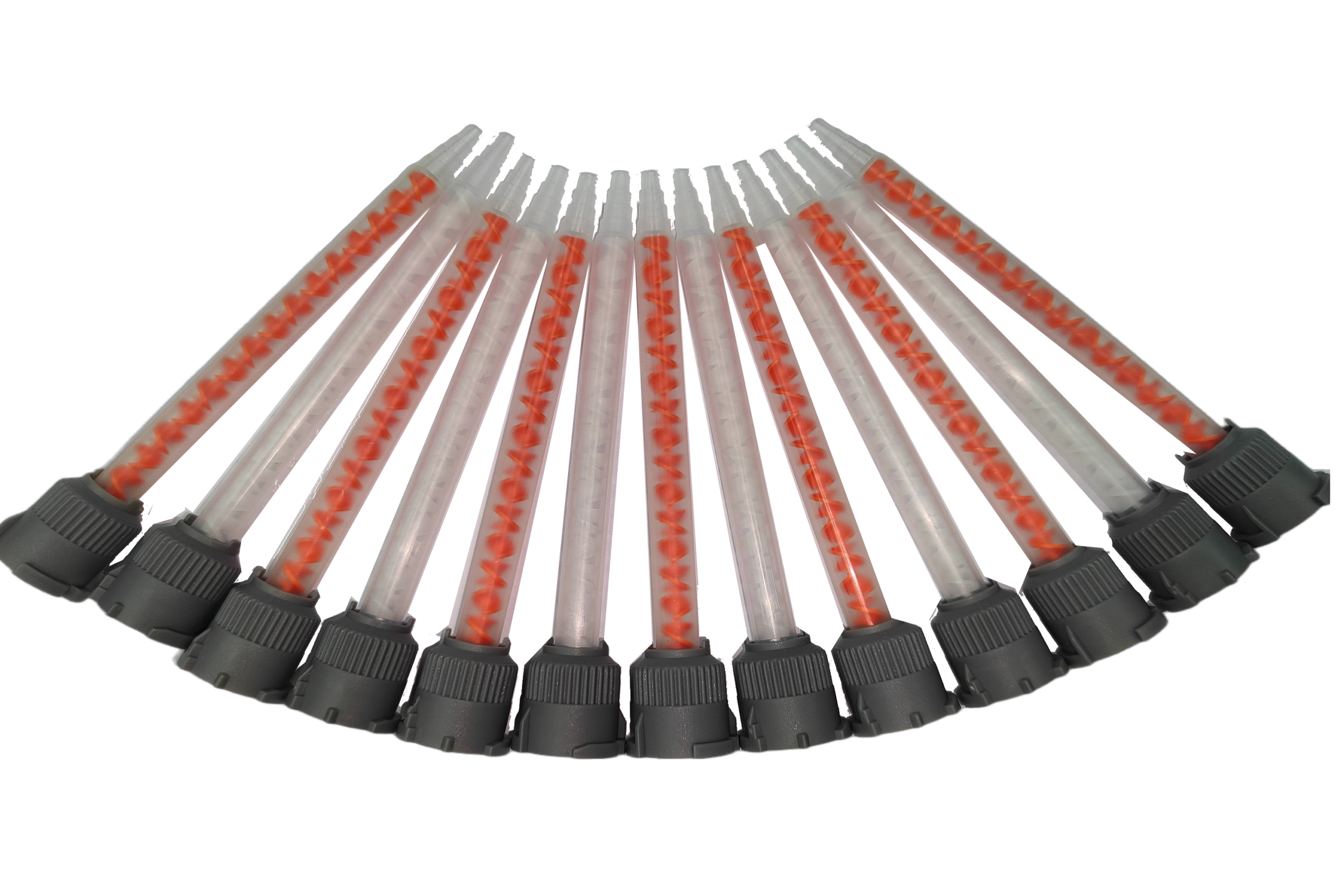

Static mixing nozzles have become a crucial component in various industries where precise and efficient mixing of two-part materials is required. These disposable devices are designed to homogenize and blend substances like adhesives, resins, sealants, and other reactive materials with ease. While some may question the practicality of disposable mixing nozzles, this article aims to shed light on the advantages and reasons behind their widespread adoption.

Eliminating Cross-Contamination

One of the primary reasons why static mixing nozzles are disposable is to prevent cross-contamination between different materials. Many industrial processes involve using reactive chemicals that can harden and cure over time. By using disposable nozzles for each application, the risk of residual material from a previous task contaminating the subsequent mix is significantly reduced. This ensures the integrity of the end product and maintains consistent quality.

Improved Mixing Efficiency

Static mixing nozzles are engineered to create a turbulent flow that facilitates the thorough blending of two-part materials. These nozzles consist of multiple internal elements, such as helical elements, to induce chaotic mixing and ensure a homogeneous mixture. Over time, these internal elements may wear out or become clogged, leading to reduced mixing efficiency. By using disposable nozzles, manufacturers can guarantee optimal mixing performance with each application, resulting in better product quality.

Time and Cost Savings

Disposable static mixing nozzles offer significant time and cost savings in various industrial settings. Their ready-to-use nature eliminates the need for cleaning and maintenance between uses, saving valuable production time. Cleaning conventional static mixers can be a labor-intensive and time-consuming process, whereas disposable nozzles can be swiftly replaced, minimizing downtime and maximizing productivity.

Easy Handling and Storage

Static mixing nozzles are often used in applications where mobility is essential. Disposable nozzles are lightweight and compact, making them easy to handle and store. Their compact size allows for convenient transportation and storage, especially in remote or on-site operations. This feature proves especially valuable for fieldwork and locations where access to cleaning facilities might be limited.

Consistent Performance

Disposable static mixing nozzles are manufactured under stringent quality controls, ensuring consistent performance from one nozzle to another. Unlike reusable nozzles, where variations may occur due to wear or damage, disposable nozzles offer uniformity and reliability in the mixing process. This consistency is critical in industries where product quality and performance directly impact customer satisfaction and safety.

Environmental Considerations

Although the disposable nature of these nozzles might raise environmental concerns, many manufacturers produce them using recyclable materials. Additionally, the reduction of chemical waste through proper material mixing and less product spoilage outweighs the environmental impact of using disposable nozzles. Many companies are also working towards developing more sustainable and biodegradable options to minimize their ecological footprint.

Conclusion

By using disposable nozzles, industries can guarantee consistency in mixing performance, maintain product quality, and eliminate the risk of cross-contamination. These nozzles not only save valuable time and costs but also simplify handling and storage, making them ideal for on-the-go applications.

In essence, disposable static mixing nozzles represent a pragmatic and efficient solution, streamlining industrial processes and ensuring high-quality end products. By embracing these advancements and continuing to innovate, industries can strike a balance between productivity and environmental consciousness. As we move forward, collaboration between manufacturers, consumers, and environmental advocates will play a pivotal role in shaping a more sustainable future for disposable static mixing nozzles and beyond.