Simple Answer: Adhesives that require static mixing nozzles are available: Two-Component Epoxies, Polyurethane Adhesives, Methyl Methacrylate (MMA) Adhesives, Silicone Adhesives, Hybrid Adhesives. Details→

Adhesives, also commonly referred to as glues or bonding agents, are substances used to join two or more materials together. They work by creating a bond between the surfaces they are applied to, essentially “sticking” them together. Adhesives come in a wide variety of types, each designed for specific applications, and they can be broadly categorized into two main groups:

Chemical Adhesives: These adhesives form bonds through chemical reactions. They typically consist of two or more components that react with each other to create a strong bond. Epoxy and cyanoacrylate adhesives (commonly known as superglue) are examples of chemical adhesives.

Mechanical Adhesives: Mechanical adhesives, on the other hand, create bonds through physical interlocking mechanisms. This category includes adhesives like pressure-sensitive tapes and hot melt adhesives.

The choice of adhesive depends on various factors, such as the materials being bonded, environmental conditions, and the required bond strength.

How Do Adhesives Work?

The effectiveness of an adhesive lies in its ability to create a strong and durable bond between two surfaces. The basic principle behind adhesive bonding is to maximize the surface area of contact between the adhesive and the materials being bonded.

When an adhesive is applied, it spreads over the surfaces and enters into tiny irregularities and pores present on the material’s surface. This creates a mechanical and/or chemical bond between the adhesive and the materials, resulting in adhesion. The adhesive then cures or sets, solidifying this bond.

The Role of Mixing Nozzles

Now that we have a basic understanding of adhesives, let’s explore the role of static mixing nozzles in adhesive applications.

What Are Static Mixing Nozzles?

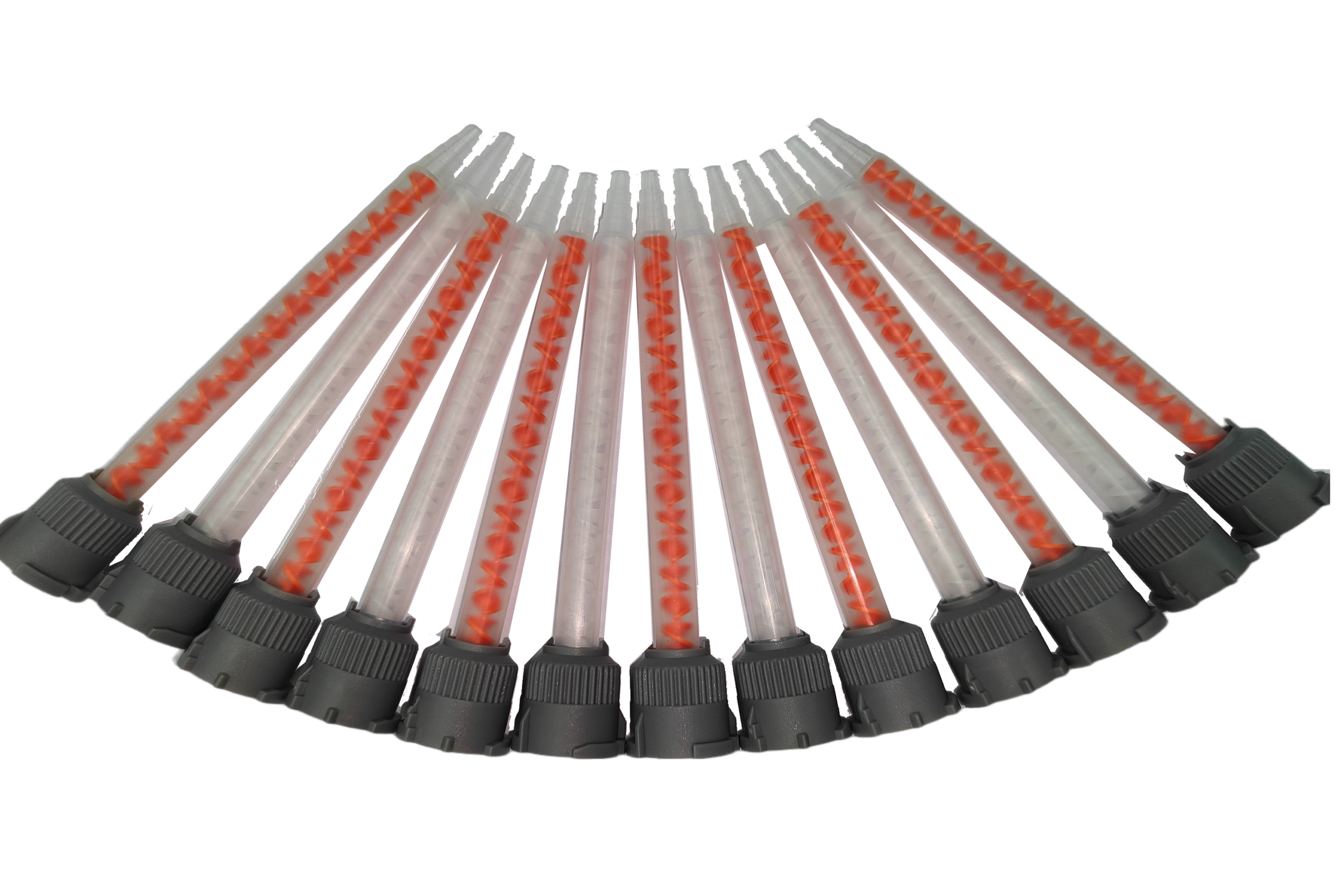

Static mixing nozzles, also known as motionless mixers or inline mixers, are specialized components used in adhesive dispensing systems. They are designed to ensure thorough and homogenous mixing of two or more adhesive components before they are applied. These components are particularly important for adhesives that consist of multiple parts or require precise ratios of components to function effectively.

Static mixing nozzles are typically made of plastic or metal and have a unique internal structure. They contain a series of helical elements or baffles that force the adhesive components to mix as they pass through the nozzle. This mixing action occurs without the need for external mechanical agitation, hence the term “static.”

Types of Adhesives That Require Static Mixing Nozzles

Not all adhesives require static mixing nozzles. Their necessity largely depends on the type of adhesive being used. Let’s take a closer look at the types of adhesives that benefit from the use of static mixing nozzles:

-

Two-Component Epoxies:

Two-component epoxy adhesives consist of a resin and a hardener. These components must be mixed in precise proportions to achieve the desired bond strength. Static mixing nozzles are essential for ensuring thorough and consistent mixing of these components before application.

-

Polyurethane Adhesives:

Polyurethane adhesives are versatile and widely used in various industries. They often come in two-component formulations that require proper mixing to activate the adhesive properties. Static mixing nozzles ensure a consistent mix, enhancing bond performance.

-

Methyl Methacrylate (MMA) Adhesives:

MMA adhesives are known for their fast curing times and high bond strengths. To achieve optimal results, these adhesives need to be mixed evenly and quickly. Static mixing nozzles excel in achieving this.

-

Silicone Adhesives:

Some silicone adhesives, especially those used in aerospace and automotive applications, are formulated as two-component systems. Static mixing nozzles help in achieving a uniform mix, ensuring a reliable bond.

-

Hybrid Adhesives:

Hybrid adhesives combine the best features of multiple adhesive types. They often come in two-component formulations and benefit from static mixing nozzles to ensure consistent perform

Advantages of Using Static Mixing Nozzles

Now that we know which adhesives require static mixing nozzles, let’s explore the advantages of incorporating these nozzles into your adhesive application process:

-

Consistency:

Static mixing nozzles provide a consistent and homogenous mix of adhesive components, reducing the risk of uneven bonding, voids, or weak spots in the adhesive joint.

-

Reduced Waste:

By ensuring thorough mixing, static mixing nozzles help minimize adhesive waste. Users can confidently apply the adhesive without worrying about uneven or incomplete mixing.

-

Improved Bond Strength:

Properly mixed adhesives generally exhibit better bond strength and overall performance. Static mixing nozzles contribute to this by consistently blending adhesive components.

-

Time Efficiency:

In many applications, time is of the essence. Static mixing nozzles enable rapid and efficient mixing, allowing for quicker adhesive application and curing.

-

Cleaner Application:

The use of static mixing nozzles reduces the mess associated with manual mixing methods. This can be especially important in industries where cleanliness and precision are paramount.

-

Customization:

Static mixing nozzles come in various sizes and configurations, allowing users to choose the right nozzle for their specific adhesive and application requirements.

Common Applications of Static Mixing Nozzles

Static mixing nozzles find applications in a wide range of industries and processes. Here are some common scenarios where they are used:

-

Automotive Manufacturing:

Static mixing nozzles are utilized for bonding components in vehicles, such as panel bonding, structural bonding, and windshield installation.

-

Construction:

They are used for anchoring bolts, dowels, and rebar, as well as in concrete repair and sealing applications.

-

Aerospace:

In the aerospace industry, static mixing nozzles are used for bonding composite materials and assembling aircraft components.

-

Electronics:

Adhesive bonding is essential in the assembly of electronic devices, and static mixing nozzles ensure precise application.

-

Medical Devices:

The medical industry relies on adhesive bonding for various applications, including device assembly and wound closure.

-

Woodworking:

In woodworking, static mixing nozzles are used for laminating, edge banding, and veneer bonding.

-

General Construction and Repair:

For DIY enthusiasts and general repair work, static mixing nozzles simplify the application of epoxy, polyurethane, and other adhesives.

Selecting the Right Static Mixing Nozzle

Choosing the right static mixing nozzle for your adhesive application is essential to achieve the desired results. Here are some factors to consider:

-

Adhesive Type:

The type of adhesive you are using determines the compatibility of the mixing nozzle. Different adhesives may require specific nozzle materials or designs.

-

Flow Rate:

Consider the flow rate required for your application. Static mixing nozzles are available in various sizes, each designed to accommodate different flow rates.

-

Mixing Ratio:

Ensure that the mixing nozzle you choose matches the required mixing ratio of your adhesive components.

-

Viscosity:

Some adhesives have higher viscosities than others. Choose a nozzle that can handle the viscosity of your adhesive without clogging or slowing down the mixing process.

-

Nozzle Length:

The length of the nozzle can affect the degree of mixing. Longer nozzles may provide more thorough mixing, but they may not be suitable for all applications due to space constraints.

-

Disposable or Reusable:

Decide whether you need disposable or reusable mixing nozzles based on your application frequency and requirements.

Proper Usage and Maintenance

To ensure the effectiveness of static mixing nozzles, it’s crucial to use and maintain them correctly. Here are some tips:

-

Follow Manufacturer Recommendations:

Always follow the manufacturer’s instructions for the specific mixing nozzle and adhesive you are using.

-

Pre-Flush the Nozzle:

Before starting a new application, it’s a good practice to pre-flush the nozzle with a small amount of adhesive to remove any residual material from the previous use.

-

Clean Regularly:

Depending on the adhesive being used, static mixing nozzles may need periodic cleaning or replacement. Consult the manufacturer’s guidelines for cleaning recommendations.

-

Storage:

Store unused static mixing nozzles in a clean and dry environment to prevent contamination.

-

Safety Precautions:

Adhesives can be hazardous, so always wear appropriate personal protective equipment (PPE) when handling and applying them.