Achieving thorough and consistent mixing is crucial when working with epoxy adhesives. Proper mixing ensures that the resin and hardener components blend homogeneously, leading to optimal adhesive performance. However, there are instances where the mixing process may not produce satisfactory results. In this article, we’ll explore common reasons why adhesives may not mix thoroughly when using epoxy mixing nozzles and provide troubleshooting tips to overcome these challenges.

Incorrect Mixing Ratio:

One of the primary reasons for incomplete mixing is an incorrect mixing ratio. Epoxy adhesives require precise proportions of resin and hardener to achieve the desired bond strength and curing characteristics. It is crucial to ensure that the cartridges or containers holding the resin and hardener are properly calibrated and that the correct mixing ratio is maintained throughout the dispensing process.

To address this issue, carefully verify the labeling and instructions provided by the adhesive manufacturer. Utilize calibrated measuring devices or syringes to ensure accurate proportions of the components before loading them into the dual cartridge dispenser or gun.

Improper Nozzle Attachment:

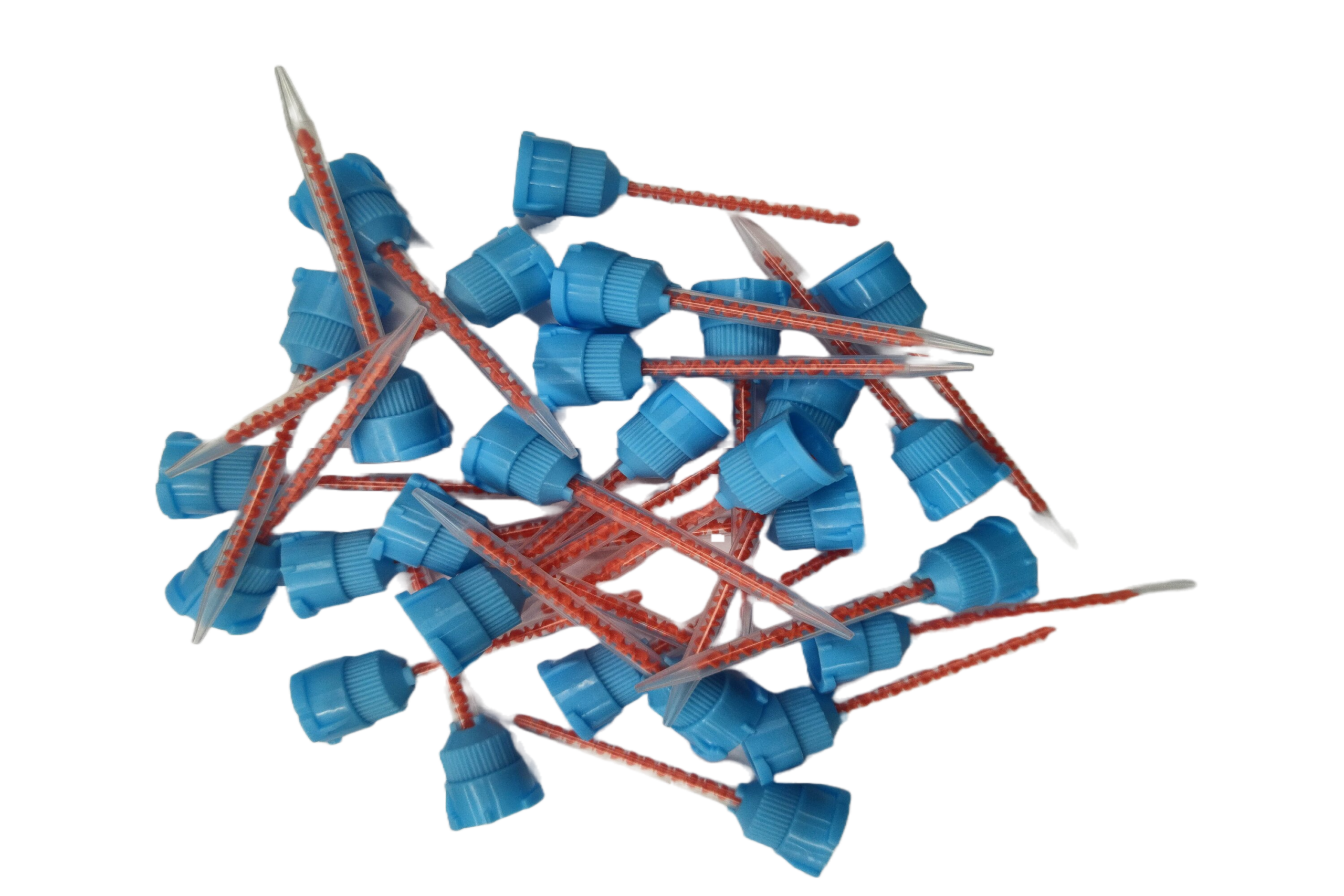

Improper attachment of the mixing nozzle can lead to leaks, air pockets, or uneven flow, resulting in incomplete mixing. It is essential to securely attach the nozzle to the dual cartridge or dispenser to create a tight seal and maintain consistent pressure.

Before dispensing the adhesive, double-check that the mixing nozzle is correctly aligned and firmly connected. Apply slight pressure to ensure a secure fit, minimizing the chances of any component leakage or disruption in the mixing process.

Partially Blocked Nozzle:

Partially blocked mixing nozzles can impede the proper flow of both resin and hardener, preventing thorough mixing. Over time, adhesive residue or other contaminants may accumulate within the nozzle, obstructing the components’ passage.

To address this issue, inspect the mixing nozzle before each use. If you notice any blockages or hardened residue, clean the nozzle thoroughly or replace it with a fresh one. This ensures an unobstructed flow and promotes effective mixing.

Insufficient Mixing Time:

Epoxy adhesives require a specific mixing time to ensure complete blending of the resin and hardener components. Insufficient mixing time can result in an adhesive mixture that is not homogeneous, leading to weakened bond strength or inadequate curing.

Refer to the manufacturer’s instructions for the recommended mixing duration. Take care to mix the adhesive components thoroughly, typically by squeezing the dual cartridge dispenser or gun and dispensing a small amount of adhesive until the mixture appears uniform. Adhere to the specified mixing time to allow the chemical reaction between the components to occur fully.

Inadequate Dispensing Pressure:

Inconsistent or insufficient pressure during adhesive dispensing can hinder proper mixing. When using a dual cartridge dispenser or gun, it is crucial to apply sufficient and consistent pressure to facilitate the even flow of the resin and hardener components.

Ensure that you are squeezing the trigger or applying pressure to the dispenser handle consistently and with the appropriate force. This consistent pressure promotes the thorough mixing of the adhesive and minimizes the risk of incomplete blending.

Viscosity Differences:

Viscosity discrepancies between the resin and hardener components can impact the mixing process. If the components have significantly different viscosities, it can be challenging to achieve uniform blending.

Consider selecting a mixing nozzle specifically designed for materials with varying viscosities. These nozzles are designed to aid in achieving effective mixing, even when the components have different flow properties. Consult with adhesive manufacturers or suppliers to identify suitable mixing nozzles for your specific epoxy adhesive formulation.

Temperature and Environmental Factors:

Temperature and environmental conditions can influence the behavior of epoxy adhesives, affecting the mixing process. Extreme temperatures or inappropriate storage conditions may compromise the adhesive’s performance and hinder thorough mixing.

Follow the adhesive manufacturer’s guidelines regarding recommended temperature ranges and storage conditions. Ensure that the adhesive components are stored in the appropriate environment and adhere to the recommended temperature range during the mixing and dispensing process. This helps maintain the adhesive’s integrity and facilitates optimal mixing.

Conclusion:

To ensure successful mixing, it is imperative to carefully follow the adhesive manufacturer’s instructions, including recommended mixing ratios, proper attachment of mixing nozzles, and appropriate mixing times. Regular inspection and maintenance of equipment, such as cleaning or replacing mixing nozzles, are also crucial for preventing blockages and maintaining consistent flow.

Professionals in the industry should also consider investing in high-quality dual cartridge dispensers or guns, as well as specialized mixing nozzles designed for specific adhesive viscosities. This proactive approach will enhance efficiency, accuracy, and consistency in the mixing process, leading to stronger and more reliable bonds.