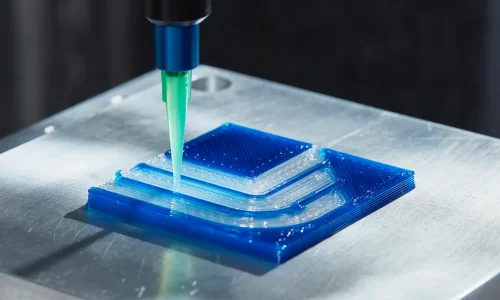

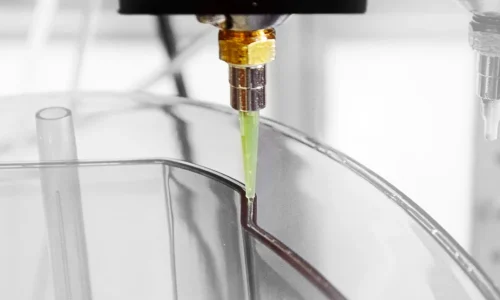

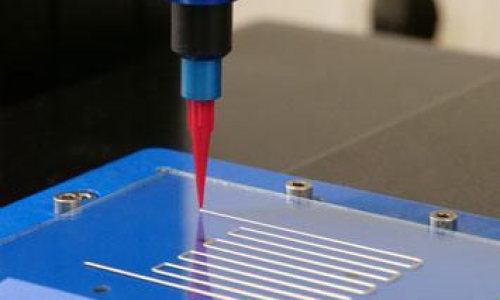

Industrial Sealants & Thick Fluid Coating

Well-suited for dispensing silicones, polyurethane sealants, and particle-filled coatings. With enhanced flow capacity and durability, these tips maintain production efficiency, reduce downtime, and avoid the frequent tip replacements required in heavy-duty manufacturing processes.