Industrial Adhesive Bonding

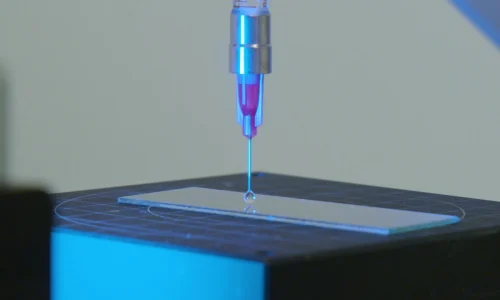

Designed for fast-curing adhesives such as cyanoacrylates and anaerobics. Superior flow precision and anti-clogging features reduce waste and enhance bonding quality and speed across consumer and industrial product assembly.