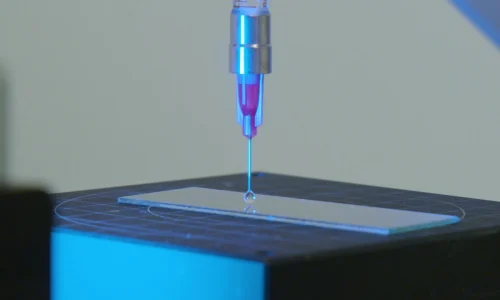

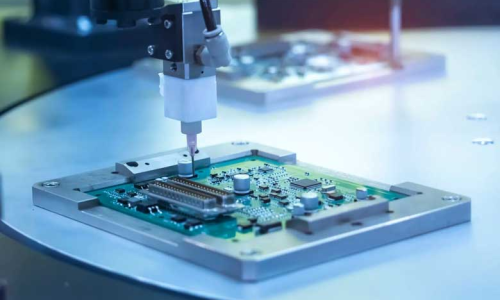

General Laboratory & Industrial Applications

Widely used for controlled dispensing in laboratory settings, chemical processing, and small-scale assembly. The non-sharp tip ensures operator safety while maintaining excellent precision and flow consistency for fluid transfer or coating tasks.