Industrial Manufacturing & Surface Coating

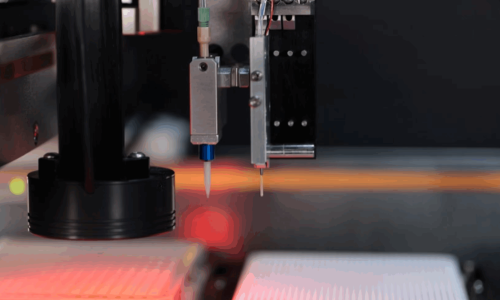

Ideal for spreading adhesives, oils, and release agents during production workflows or manual processes. The efficient brush design ensures uniform fluid thickness, reduces waste, and improves finishing quality — boosting productivity in manufacturing and surface treatment operations.