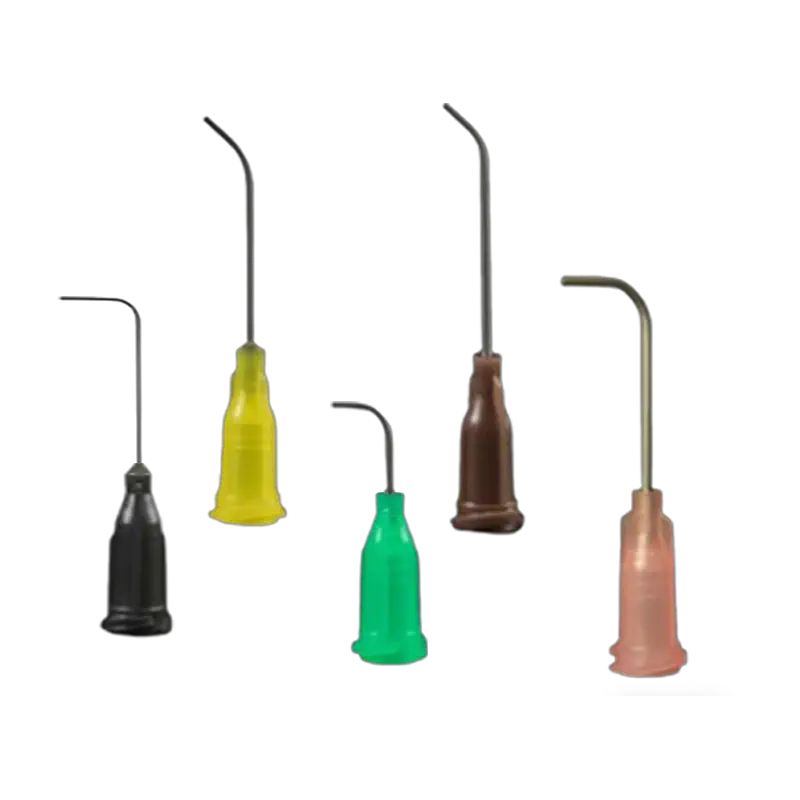

Custom Dispensing Tips

Downloads

Frequently Asked Questions (FAQ)

How do I choose the right dispensing tip for industrial adhesive applications?

The right dispensing tip is primarily determined by fluid viscosity and required deposit size, with gauge and hub type defining performance limits. Low-viscosity materials typically require higher-gauge tips for precise dots, while medium-to-high viscosity adhesives need lower-gauge tips to avoid excessive backpressure. Tip material and hub strength should also match dispensing pressure and automation level. Incorrect selection may cause clogging, unstable flow, or inconsistent bead profiles.

What is the difference between PP hub and all-metal hub dispensing tips?

PP hub and all-metal hub dispensing tips differ mainly in pressure resistance, durability, and suitability for automation. PP hubs with stainless steel needles are cost-effective for most manual or low-pressure dispensing tasks. All-metal hubs offer higher mechanical strength and dimensional stability, making them better suited for high-pressure, abrasive materials, or automated systems. Choosing beyond actual pressure requirements may increase cost without performance benefit. Btektech supports both configurations and can help evaluate which option aligns best with your dispensing pressure and system setup.

How does dispensing tip gauge size affect flow rate and dispensing accuracy?

Dispensing tip gauge directly controls inner diameter, which determines flow rate, backpressure, and achievable precision. Higher-gauge tips (smaller ID) are suitable for low-viscosity fluids such as UV adhesives or cyanoacrylates, enabling fine dots and thin lines. Lower-gauge tips (larger ID) support viscous materials like silicones or epoxies, reducing pressure buildup and flow instability. Using an undersized gauge can lead to clogging or inconsistent dispensing.

Are dispensing tips universal and compatible with standard Luer Lock systems?

Most industrial dispensing tips are compatible with standard Luer Lock interfaces, allowing interchangeability across common systems. This compatibility supports use with most manual syringes and automated dispensing valves without equipment modification. However, proprietary or non-standard connectors may require verification. Confirming interface standards in advance reduces integration risk and prevents fit or sealing issues in production environments. Btektech can assist in confirming interface compatibility before ordering when system specifications are unclear.

When should custom-designed dispensing tips be used instead of standard tips?

Custom dispensing tips are recommended when standard gauges, lengths, or geometries cannot meet specific application constraints. Typical cases include deep or recessed dispensing points, unusual bead orientation, abrasive fillers, or strict clearance limitations. Custom designs are evaluated based on material compatibility, achievable tolerances, and production feasibility. Early testing or sampling is advised to reduce validation risk before scaling to full production. Btektech works with customers during evaluation and testing phases to develop custom tips that align with real process conditions.

Learn More About Precision Dispensing

Our blog is designed to help you deepen your knowledge of fluid dispensing processes, optimize your production line, and select the best components for your specific challenges. Explore articles that connect industry insights with practical solutions.