Introduction:

For farriers, hoof care specialists, and veterinarians, achieving reliable hoof repairs is a constant challenge. Hooves are exposed to continuous stress — compression, flexing, abrasion, moisture, and environmental changes — all of which can lead to cracks, defects, or conditions like laminitis that compromise their strength and function.

Traditional repair methods such as nailing or using hoof pads may help restore the hoof’s shape, but they often fall short when it comes to reinforcing the hoof wall itself.

By contrast, using static mixing nozzles with two-component hoof repair adhesives ensures precise mixing, consistent curing, and minimal waste. This modern approach delivers stronger, longer-lasting results for both equine and cattle hoof care — helping maintain hoof integrity, stability, and overall comfort.

This blog firstly explores how modern adhesive technology is transforming hoof repair—from understanding why precise two-component mixing matters, to revealing how static nozzles simplify the process and improve curing quality. It also highlights practical guidance on selecting the right tools and materials to achieve durable, professional-grade results that keep horses and cattle sound and healthy.

Why More Hoof Care Experts Are Using Dual-Component Adhesives

Manual blending of adhesives often leads to curing issues due to uneven ratios or poor mixing. Dual-component adhesive systems solve this by providing controlled and consistent material delivery.

When paired with a static mixing nozzle, the two parts are automatically blended in the correct ratio, ensuring uniform texture and dependable bonding strength every time. This reduces human error and guarantees optimal curing even under challenging stable or field conditions.

How Static Nozzles Work

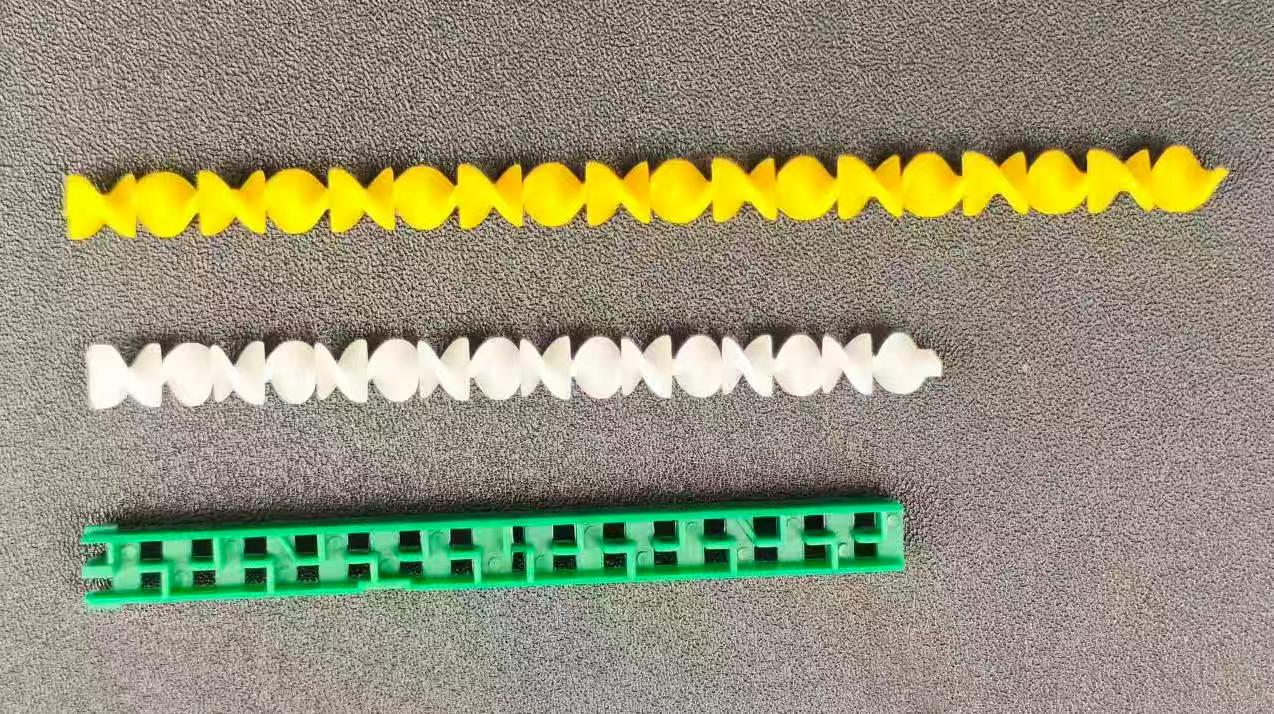

A static mixer contains internal spiral or straight-flight elements designed to split and recombine two liquid components as they pass through the chamber.

This repeated folding and redirection create a homogeneous mixture by the time it exits the nozzle tip.

For hoof technicians, this means achieving a professional-grade blend and cure without needing complex tools or chemical expertise. Compared with manual stirring, a static nozzle dramatically improves both repair efficiency and bond durability.

Common Mixing Problems in Hoof Restoration

| Issue Type | Specific Manifestation | Resulting Impact |

| Incomplete Curing | An imbalanced mixing ratio causes localized poor curing | Creates weak bonding points; the repair layer may easily detach |

| Internal Stress or Brittle Points | Uneven mixing leads to inconsistent curing, forming stress concentration areas | Prone to peeling or cracking during use |

| Abnormal Viscosity or Flow | Improper mixer structure or size affects extrusion resistance | Causes operational difficulty or insufficient material mixing |

These problems can all be avoided by matching the right adhesive to the correct static mixing nozzle.

How to Choose the Right Tip for Hoof Care

Selecting the right nozzle is essential for achieving proper mixing pressure and a consistent adhesive flow.

As farrier expert Dean Lewis (CJF, AWCF) notes in his Guide to Using Hoof Glue and Rebuild Materials, the most commonly used hoof repair adhesives include:

- Polyurethane (PU) Hoof Glue – Offers flexibility and shock absorption, making it ideal for general repairs.

- Acrylic Glue – Cures quickly and can be easily shaped, often used for cosmetic or quick-fix applications.

- Epoxy Glue – Provides high strength and excellent moisture resistance, suitable for more demanding structural restorations.

The viscosity of each adhesive determines the most suitable mixer size and internal design.

Using a nozzle that’s too narrow or with the wrong configuration can lead to uneven mixing, excessive extrusion resistance, or weak bonding performance — all of which compromise repair quality and waste material.

Choosing the right hoof repair kit and mixing nozzle ensures every application is clean, precise, and durable.

For consistent, professional-grade results, explore Btektech’s range of static mixer nozzles engineered specifically for hoofcare applications, or reach out to Btektech for personalized technical guidance.

Conclusion

Healthy hooves are the foundation of strong, active horses and cattle. Using properly mixed two-component adhesives is essential for achieving durable and dependable repairs.

To ensure the best outcome, request expert guidance or a sample from Btektech to find the ideal nozzle for your hoof repair materials.

You can also browse our full range of dispensing consumables to enhance your hoofcare practice with reliable, high-performance solutions.

If you have any questions, feel free to contact us. We also offer product customization based on your specific needs