-

Chemical-Resistant polypropylene: Both the syringe barrel and piston are made of PP material, which will not react with aggressive solvents or oils.

-

Task-Specific Piston Designs: Choose our Rubber Piston for smooth, leak-free travel with high-viscosity fluid. For silicone-free or high-purity optics, our All-Plastic Piston eliminates the risk of elastomer contamination.

-

Versatile Outlet Configurations: Our Luer lock Outlet can be connected to a dispensing needle for precise dispensing. The Tapered Outlet offers a wide, low-resistance path for high-flow and smooth dispensing.

-

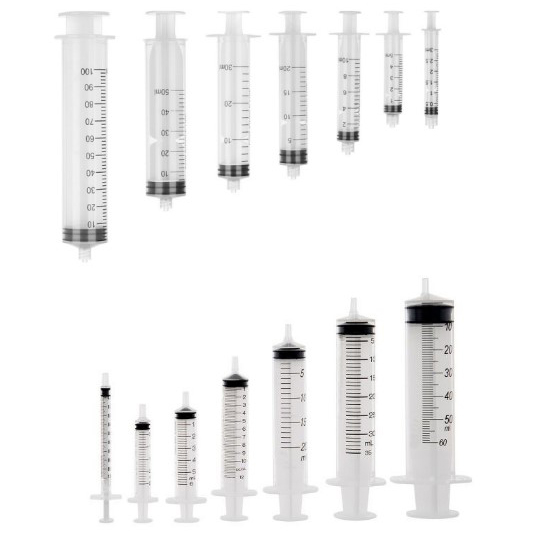

1cc to 500cc Capacity Range: We cover every manual scenario in your work. Whether you need micro-dosing for electronics or bulk refills for heavy machinery, we have the exact barrel size.