Introduction

Are standard dispensing tips failing to deliver consistent results in your production process?

In precision fluid applications, even small variations in outlet geometry, internal diameter (ID), material compatibility, or needle length can directly affect flow stability. Common issues such as clogging, dripping, stringing, or inconsistent bead size often originate from dispensing tips that are designed for general use rather than for specific fluids and application conditions.

Standard off-the-shelf tips may be sufficient for basic tasks, but they rarely meet the performance requirements of modern manufacturing—particularly in electronics assembly, laboratory automation, and fine chemical processing. As process tolerances become tighter, custom dispensing tips are increasingly required to achieve stable and repeatable material delivery.

By tailoring outlet design, ID/OD ratios, material selection, and tip length to the actual application scenario, manufacturers can significantly improve accuracy, reduce material waste, and enhance overall process stability.

How Custom Dispensing Tip Design Improves Precision Fluid Control

Precision fluid control depends on how closely the dispensing tip matches the fluid behavior and operating conditions. Poorly matched designs can introduce turbulence, pressure instability, or incomplete cut-off, all of which negatively impact consistency.

Custom dispensing tips address these challenges through several key design considerations:

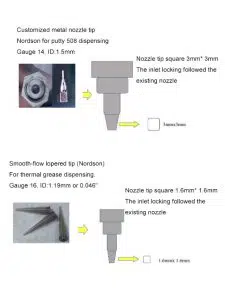

Optimized outlet geometry

Customized blunt, tapered, or stepped outlet profiles help control fluid break-off and reduce stringing, particularly when working with high-viscosity adhesives or low-surface-tension materials.

Balanced internal and external diameters

The internal diameter influences flow rate and pressure stability, while the outer diameter affects accessibility in compact assemblies. Proper ID/OD balance supports smooth, controlled material delivery.

Application-specific material selection

Using stainless steel, polypropylene, or ESD-safe polymers ensures chemical compatibility, wear resistance, and long-term reliability in demanding environments.

By aligning these parameters with real-world conditions, custom-designed tips provide measurable improvements in repeatability and process control.

Precision Application Solutions for Industrial and Laboratory Use

Btektech develops customized dispensing tips and nozzles for precision-driven industries, including:

- Electronics manufacturing

- Laboratory and industrial fluid handling

- Fine chemical processing and specialty materials

- Automated industrial assembly

Rather than acting solely as a component supplier, Btektech supports customers as a technical manufacturing partner. Producing non-standard outlet structures or micro-scale components requires practical experience in machining tolerances, material behavior, and application validation.

With more than a decade of manufacturing experience, our engineering team helps customers:

- Select outlet designs that match fluid properties and process requirements

- Minimize material loss caused by dripping or rework

- Improve consistency across automated and manual application systems

Each solution is engineered with a focus on stable flow behavior, dimensional accuracy, and long-term operational reliability.

OEM and ODM Manufacturing Support

Btektech offers flexible cooperation models through both OEM and ODM manufacturing services, supporting customers at different stages of product development.

OEM Manufacturing for Application Tips

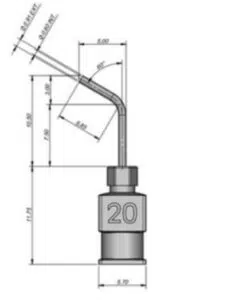

For OEM projects, we manufacture precision tips strictly according to customer-provided drawings or CAD files. Our production processes emphasize:

- Tight dimensional tolerances

- Consistent outlet geometry

- Reliable batch-to-batch repeatability

This model is well suited for customers with finalized designs who require stable mass production.

ODM Development for Custom Tip Solutions

For ODM projects, Btektech participates earlier in the development cycle. Customers can provide performance goals, fluid characteristics, or application challenges—even without finalized drawings.

Our engineering team will:

- Evaluate operating conditions and real application scenarios

- Optimize structural design, dimensions, and material choice

- Produce prototypes for functional testing and validation

This approach is ideal for complex applications or new product development requiring tailored fluid delivery solutions.

Design Options and Customization Capabilities

Custom Length Configuration

Tip length can be adjusted to suit automated systems, manual applicators, or confined application areas. Appropriate length selection improves positioning accuracy and operator control.

Material Selection Options

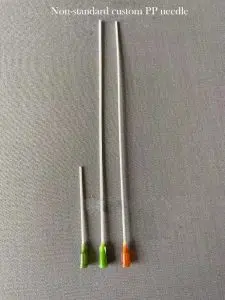

Custom solutions are available in a range of materials, including:

- Stainless steel (SS316/SS302) for abrasive or high-viscosity materials

- Polypropylene (PP) for general-purpose or disposable use

- ESD-safe polymers for static-sensitive electronics applications

Material selection is based on chemical compatibility, viscosity, and operating conditions.

Manufacturing Based on Drawings or Samples

Whether based on technical drawings, physical samples, or reference images, Btektech supports flexible development paths while maintaining consistent quality standards.

Quality Control and Manufacturing Consistency

Consistent dispensing performance depends on strict quality control throughout the manufacturing process. Btektechimplements comprehensive quality assurance measures, including:

- Incoming raw material inspection

- In-process dimensional and visual checks

- Final functional and appearance inspections before shipment

These controls help ensure precise outlet dimensions, stable flow behavior, and reliable performance in real-world applications.

Engineering Support and Value-Added Services

Our R&D and engineering teams specialize in precision metal and plastic component manufacturing. Once requirements are confirmed, we support a smooth transition from prototyping to volume production.

Additional services such as customized packaging and labeling help customers streamline supply chains and accelerate global market entry.

Conclusion: A Trusted Manufacturer of Custom Dispensing Tips

Selecting the right custom dispensing tips is essential for achieving consistent and repeatable results in precision fluid application. By optimizing outlet design, materials, and manufacturing quality, manufacturers can improve product performance, reduce waste, and enhance production efficiency.

With over ten years of OEM and ODM manufacturing experience, Btektech delivers reliable solutions for precision fluid application components. From concept development to mass production, we provide technical expertise, flexible manufacturing capacity, and dependable support.

➡ Contact Btektech to discuss your application requirements and receive a customized solution tailored to your process.