In the world of adhesives, the secret to a successful bond often lies in the intricate dance between adhesive viscosity and the static mixing nozzle. The viscosity of an adhesive—the measure of its thickness or resistance to flow—can significantly impact the application process. Pair this with the right static mixing nozzle, and you’re on your way to achieving optimal adhesive performance. In this blog post, we’ll explore the fascinating relationship between adhesive viscosity and static mixing nozzles and how this synergy shapes the world of adhesive applications.

Adhesive Viscosity:

Viscosity is a fundamental property of liquids, including adhesives. It quantifies how easily or reluctantly a fluid flows. Adhesives come in a wide range of viscosities, from thin and runny to thick and gooey. This property has a profound effect on how adhesives are dispensed, mixed, and applied.

Static Mixing Nozzles:

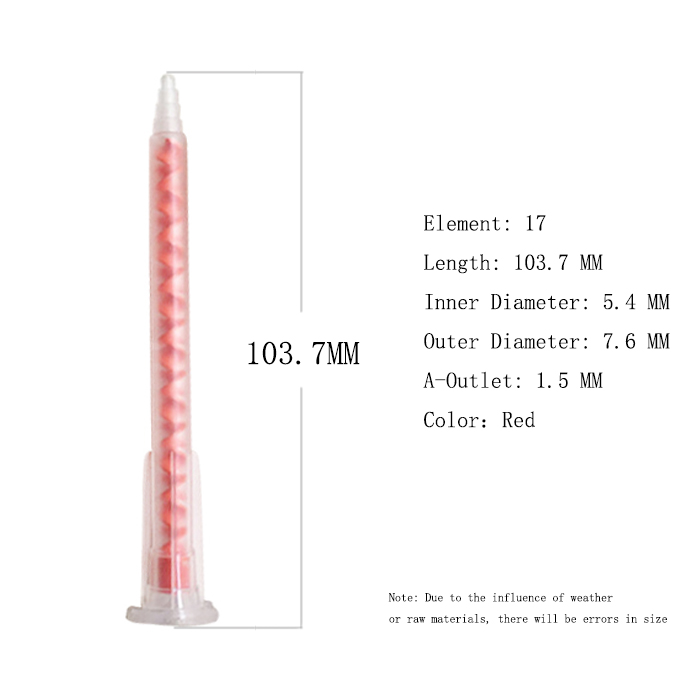

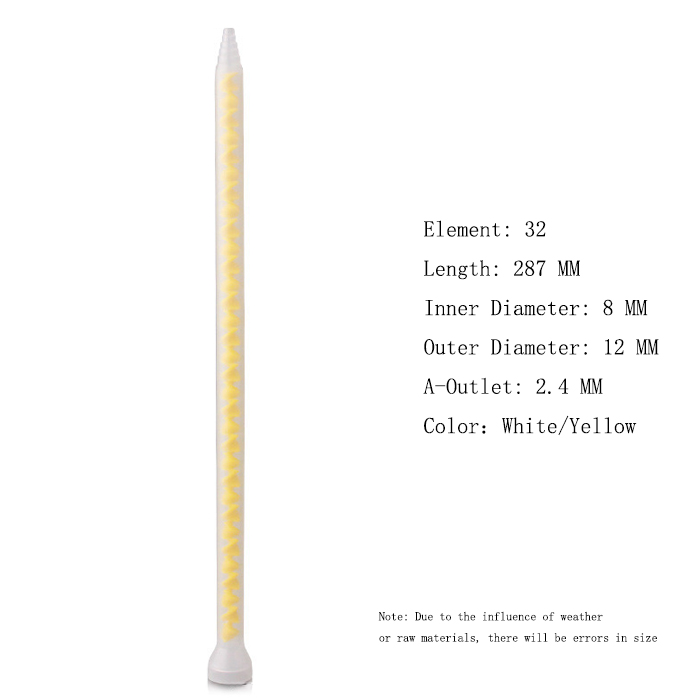

Static mixing nozzles play a crucial role in adhesive application systems. They’re designed to blend two or more components of an adhesive, ensuring a homogeneous mix before it’s dispensed. These nozzles typically consist of a series of internal elements that twist and intermingle the adhesive components as they pass through.

The Interplay:

Now, let’s uncover the intricate relationship between adhesive viscosity and static mixing nozzles:

Low-Viscosity Adhesives and Short Nozzles:

- Adhesives with low viscosity, like watery liquids, flow easily.

- For these adhesives, shorter static mixing nozzles with fewer mixing elements are sufficient.

- Using a short nozzle prevents overmixing, which can lead to wasted adhesive and longer dispensing times.

Medium-Viscosity Adhesives and Balanced Nozzle Length:

- Adhesives with moderate viscosity require a careful balance between mixing efficiency and flow rate.

- Medium-length static mixing nozzles with an appropriate number of mixing elements work well for achieving a thorough blend without compromising the adhesive’s flow properties.

High-Viscosity Adhesives and Longer Nozzles:

- Highly viscous adhesives, such as thick gels or pastes, demand more mechanical force to mix effectively.

- Longer static mixing nozzles, equipped with multiple mixing elements, are necessary to ensure uniform mixing and homogeneity in these adhesives.

Selecting the Right Nozzle for Your Application

To ensure your adhesive application is a success, consider these key factors:

-

Know Your Adhesive:

Understand the viscosity of your adhesive and match it with an appropriate nozzle length.

-

Application Requirements:

Evaluate the desired mix quality and the specific needs of your application, which can influence nozzle selection.

-

Equipment Compatibility:

Ensure that your dispensing equipment can accommodate the chosen nozzle in terms of length and diameter.

-

Material Efficiency:

Using the right nozzle size can help minimize material waste, especially when dealing with costly adhesives.

-

Testing and Validation:

Conduct preliminary tests to verify that the selected nozzle works effectively with your adhesive formulation.

Conclusion

The relationship between adhesive viscosity and static mixing nozzles is a fundamental aspect of adhesive applications. By selecting the right nozzle length to match your adhesive’s viscosity, you can achieve a perfect blend and an efficient application process. This synergy between adhesive properties and mixing nozzles paves the way for stronger, more reliable bonds and ensures that adhesives perform their crucial roles effectively in various industries.