Epoxy mixing nozzles are critical components in dispensing two-part epoxy adhesives accurately and precisely. These nozzles come in a variety of sizes, shapes, and configurations to accommodate different epoxy types, application methods, and substrates. But have you ever wondered why some epoxy mixing nozzles have different colors? In this article, we will explore the reasons behind the various colors of epoxy mixing nozzles.

The Function of Epoxy Mixing Nozzles

Before we dive into the reasons behind the different colors of epoxy mixing nozzles, it is essential to understand their function. Epoxy mixing nozzles are designed to thoroughly mix the two components of a two-part epoxy adhesive as they pass through the nozzle. These nozzles have multiple mixing elements that ensure uniform mixing of the epoxy components. The result is a uniform mixture that is ready for immediate use.

The primary function of epoxy mixing nozzles is to blend the two components of the epoxy adhesive together to ensure optimal bond strength and reliability. These nozzles can be attached to manual or automatic dispensing guns and can be disposable or reusable, depending on the application requirements.

The Different Colors of Epoxy Mixing Nozzles

Epoxy mixing nozzles come in various colors, including black, green, clear, yellow and red. These colors are not random but serve a specific purpose.

-

Black Epoxy Mixing Nozzles:

Black epoxy mixing nozzles are used for opaque or dark-colored epoxy adhesives. They help to ensure that the mixed adhesive is fully blended and that no unmixed adhesive remains in the nozzle. Black epoxy mixing nozzles are also suitable for UV-cured epoxy adhesives.

-

Green Epoxy Mixing Nozzles:

Green epoxy mixing nozzles are used for rapid-curing epoxy adhesives. They allow for quick mixing and dispensing of the adhesive, making them suitable for time-sensitive applications. Green epoxy mixing nozzles also provide good mixing efficiency for low-viscosity adhesives.

-

Clear Epoxy Mixing Nozzles:

Clear epoxy mixing nozzles are used for clear or translucent epoxy adhesives. They allow for easy inspection of the adhesive flow and mixing, making it easier to identify any inconsistencies or problems during the application process.

-

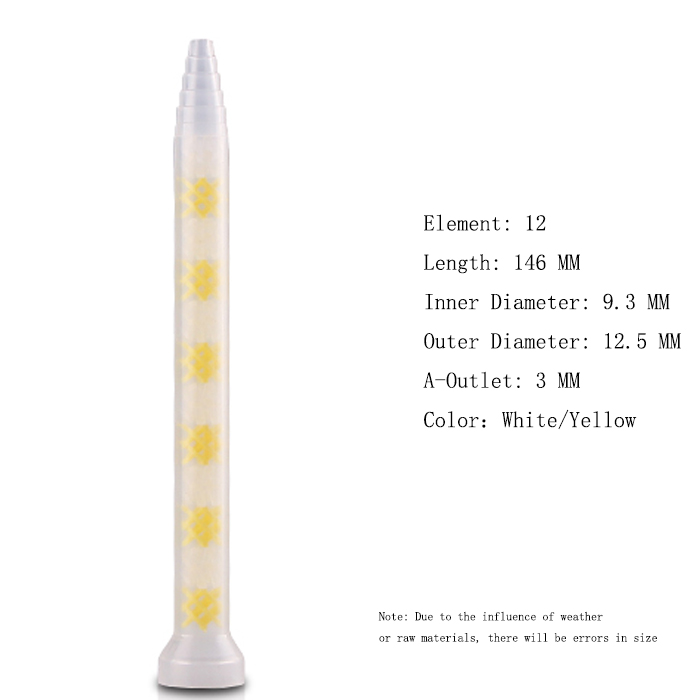

Yellow Epoxy Mixing Nozzles:

Yellow epoxy mixing nozzles are used for epoxy adhesives that contain fillers or thickeners. They provide excellent mixing efficiency for these types of adhesives, ensuring that the filler or thickener is fully blended into the adhesive.

-

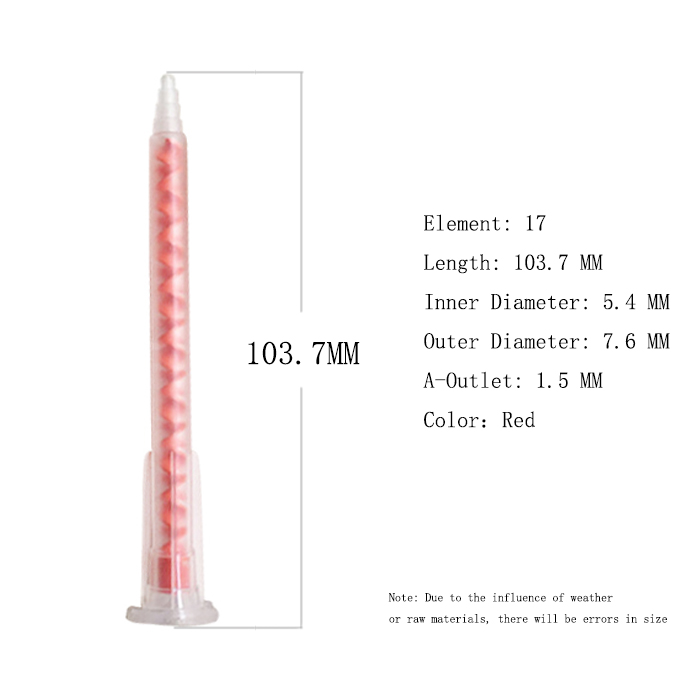

Red Epoxy Mixing Nozzles:

Red epoxy mixing nozzles are made from materials that can withstand temperatures of up to 200 degrees Celsius (392 degrees Fahrenheit) and provide excellent mixing efficiency for high-temperature epoxies. The red color coding makes it easy to identify the nozzle that is suitable for high-temperature applications, which is important for achieving optimal results.

Why Different Colors?

So, why do epoxy mixing nozzles come in different colors? The reason behind the various colors is to make it easier to identify the type of epoxy mixing nozzle needed for a specific application. By using color coding, users can quickly identify which nozzle to use for a particular epoxy type and application.

For example, if a user needs to bond two substrates that require high bond strength, they can quickly identify the green epoxy mixing nozzle and use it for their application. Similarly, if a user needs to bond two substrates that require a fast-curing epoxy, they can identify the yellow epoxy mixing nozzle and use it for their application.

Color coding also makes it easier to manage inventory and ensure that the correct epoxy mixing nozzles are available for different applications. By using a color-coded system, users can easily organize their epoxy mixing nozzles and avoid confusion.

Conclusion

The various colors of epoxy mixing nozzles serve a specific purpose and make it easier to identify the type of nozzle needed for a particular application. By using a color-coded system, users can quickly identify the correct epoxy mixing nozzle, manage their inventory effectively, and ensure optimal bond strength and reliability in their epoxy applications.