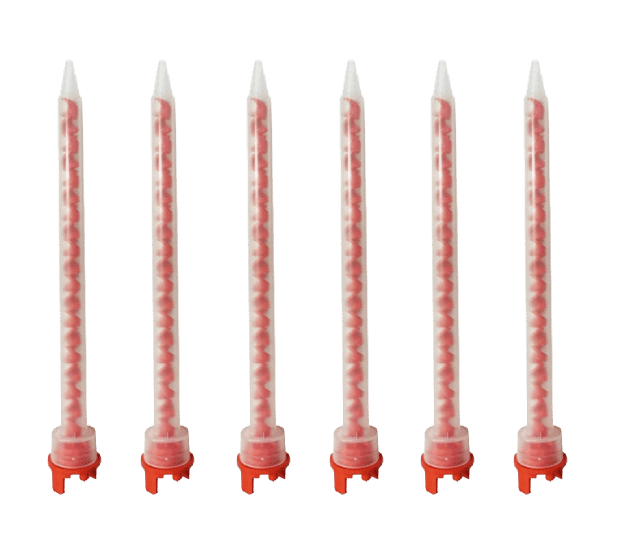

In the realm of industrial processes where accuracy and consistency are paramount, the role of custom static mixing nozzles stands out as a critical component. These specialized nozzles, meticulously designed to cater to specific requirements, offer an unparalleled level of precision in the blending of materials. Let’s delve into why these custom solutions have become indispensable in various industries.

Tailored to Perfection

Off-the-shelf mixing nozzles are versatile but fall short when it comes to addressing unique industrial needs. Custom static mixing nozzles, however, are engineered with precision, taking into account the specific viscosity, flow rates, and material properties required by a particular process. This tailoring ensures an exacting mix of materials, enhancing the quality and integrity of the final product.

Precision in Blending Ratios

One of the primary reasons for opting for customized mixing nozzles is the need for precise control over the blending ratios of components. Industries like adhesives, sealants, or chemical production demand exact proportions for optimal performance. Custom nozzles are designed to meet these stringent specifications, guaranteeing the accuracy and consistency needed for superior product outcomes.

Optimizing Manufacturing Efficiency

The design and engineering behind custom static mixing nozzles aim to optimize manufacturing processes. By ensuring the right blend, these nozzles help in minimizing waste, reducing rework, and enhancing the overall efficiency of production lines. The tailored approach directly contributes to cost savings and streamlined operations.

Meeting Diverse Industry Needs

Various industries, from automotive to aerospace, pharmaceuticals to construction, have distinct requirements that demand precise mixing solutions. Custom static mixing nozzles offer the flexibility to meet these diverse needs, whether it’s the dispensing of adhesives, coatings, resins, or other materials, each with their unique viscosity and curing requirements.

Quality Assurance and Consistency

Consistency is key in industrial settings. Custom nozzles provide the assurance of consistent mixing, minimizing variations and ensuring a uniform blend of materials. This reliability directly impacts the quality of the final product, reducing defects and enhancing overall product performance.

Conclusion

Custom static mixing nozzles have emerged as a crucial solution in industries that prioritize accuracy, efficiency, and quality. Their tailored design and precision in blending ratios offer a level of control and reliability that cannot be achieved with standard off-the-shelf alternatives. As industrial processes continue to evolve, the demand for these customized solutions will likely grow, reaffirming their significance in achieving optimal manufacturing outcomes.